Low-water-absorptivity self-extinction photo-cured waterborne polyurethane acrylate cured film as well as preparation method and application thereof

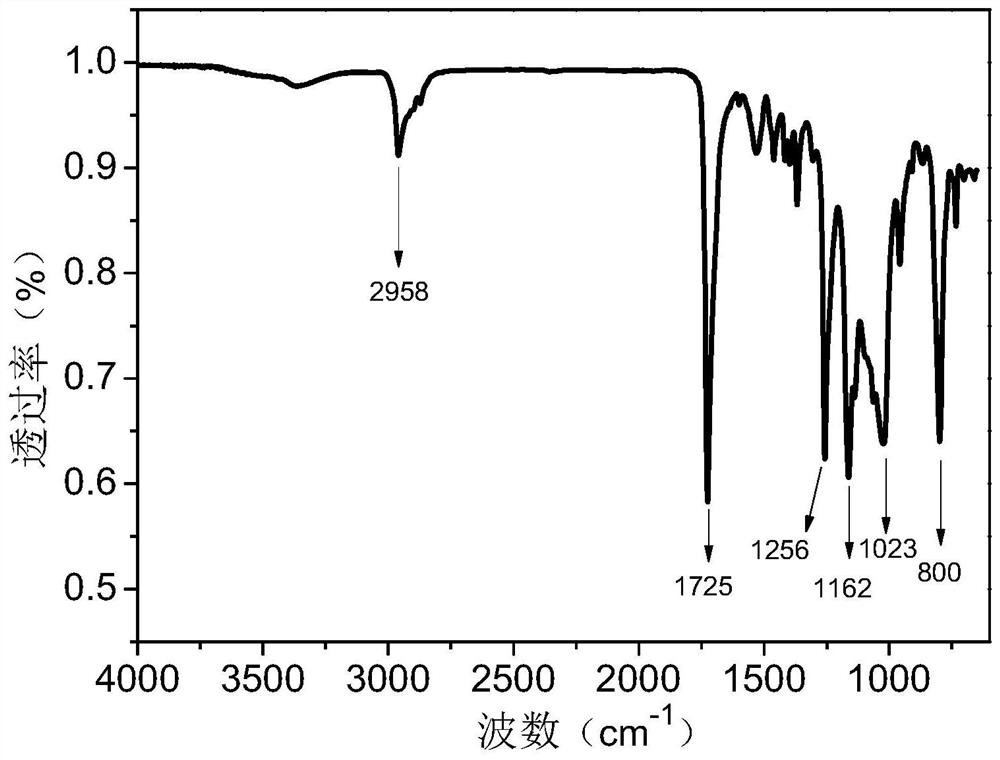

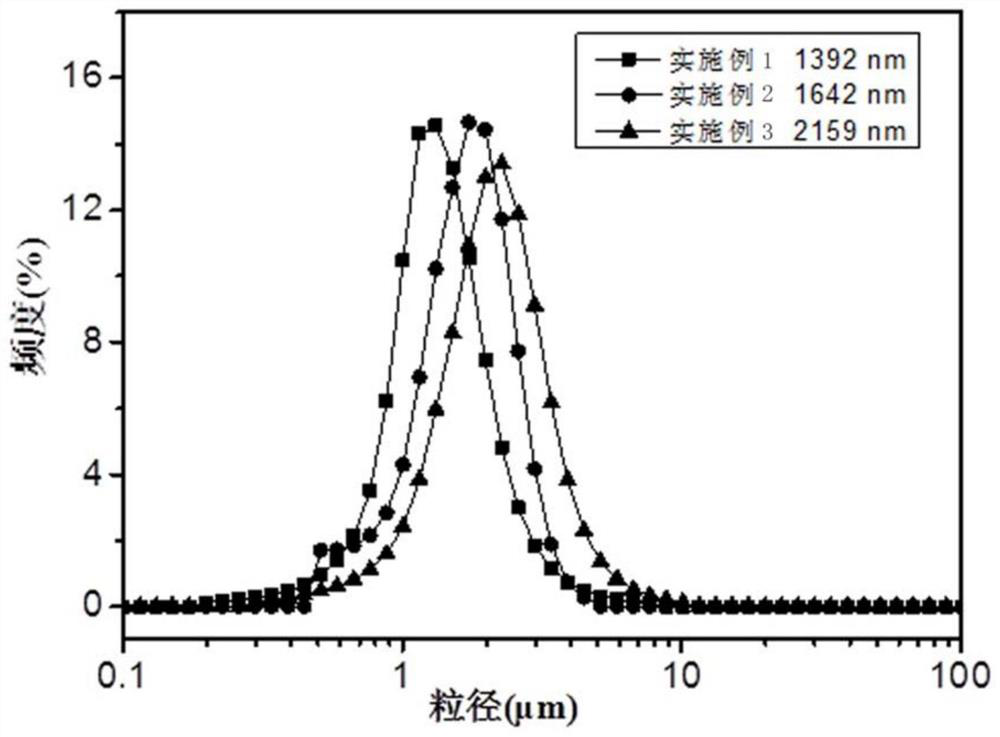

A polyurethane acrylate, low water absorption technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced substrate protection performance, reduced water resistance of the coating film, and high water absorption of the coating film, so as to reduce the water absorption rate. , Excellent water resistance, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

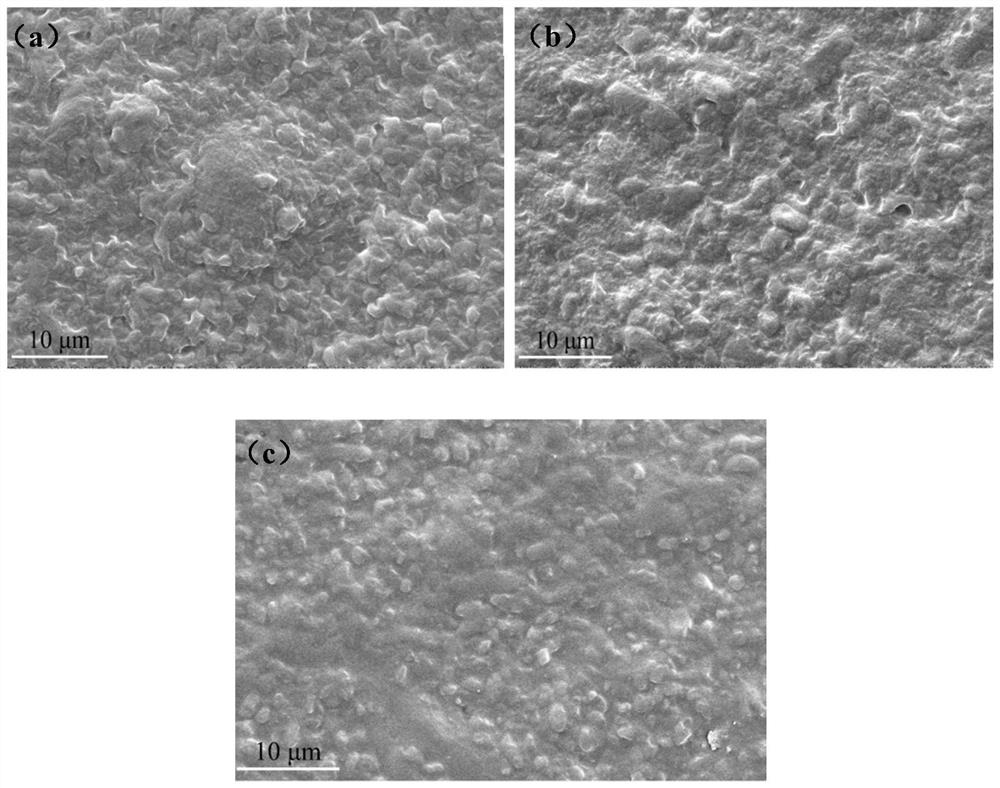

Embodiment 1

[0052] (1) Preparation of self-extinction photocurable water-based polyurethane acrylate emulsion with low water absorption

[0053] 1. 25 grams of molecular weight is 1000 polybutylene adipate diol, 2.0310 grams of molecular weight is 3000 terminal hydroxyl polydimethylsiloxane and 50 milligrams of catalyst dibutyltin dilaurate are added in the four-necked flask, under nitrogen Add 12.3593 grams of isophorone diisocyanate dropwise under atmosphere, stir at 60°C for 1 hour at a speed of 300 rpm, add 1.2186 grams of dimethylol propionic acid, and continue the reaction at 85°C for 2 hours to obtain polyurethane Prepolymer (Prepolymer I); wherein, isocyanate groups and hydroxyl groups (including the total hydroxyl groups in polybutylene adipate diol, hydroxyl-terminated polydimethylsiloxane and dimethylolpropionic acid) The molar ratio of dimethylolpropionic acid is 1.6, the mass fraction of dimethylolpropionic acid in prepolymer I is 3.0wt%, and the massfraction of hydroxyl-term...

Embodiment 2

[0064] (1) Preparation of self-extinction photocurable water-based polyurethane acrylate emulsion with low water absorption

[0065] 1. 25 grams of molecular weight is 1000 polybutylene adipate diol, 3.0709 grams of molecular weight is 3000 terminal hydroxyl polydimethylsiloxane and 50 milligrams of catalyst dibutyltin dilaurate are added in the four-necked flask, under nitrogen Add 11.7394 grams of isophorone diisocyanate dropwise under atmosphere, stir at 60°C for 1 hour at a speed of 300 rpm, add 1.2314 grams of dimethylol propionic acid, and continue the reaction at 85°C for 2 hours to obtain polyurethane Prepolymer (Prepolymer I); wherein, isocyanate groups and hydroxyl groups (including the total hydroxyl groups in polybutylene adipate diol, hydroxyl-terminated polydimethylsiloxane and dimethylolpropionic acid) The molar ratio of dimethylolpropionic acid is 1.5, the mass fraction of dimethylolpropionic acid in prepolymer I is 3.0wt%, and the massfraction of hydroxyl-term...

Embodiment 3

[0075] (1) Preparation of self-extinction photocurable water-based polyurethane acrylate emulsion with low water absorption

[0076] 1. 25 grams of molecular weight is 1000 polybutylene adipate diol, 4.3529 grams of molecular weight is 3000 terminal hydroxyl polydimethylsiloxane and 50 milligrams of catalyst dibutyltin dilaurate are added in four-necked flask, under nitrogen atmosphere Add 12.8703 grams of isophorone diisocyanate dropwise under atmosphere, stir at 60°C for 1 hour at a speed of 300 rpm, add 1.3059 grams of dimethylol propionic acid, and continue the reaction at 85°C for 2 hours to obtain polyurethane Prepolymer (Prepolymer I); wherein, isocyanate groups and hydroxyl groups (including the total hydroxyl groups in polybutylene adipate diol, hydroxyl-terminated polydimethylsiloxane and dimethylolpropionic acid) The molar ratio of dimethylolpropionic acid is 1.6, the mass fraction of dimethylolpropionic acid in prepolymer I is 3.0wt%, and the mass fraction of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com