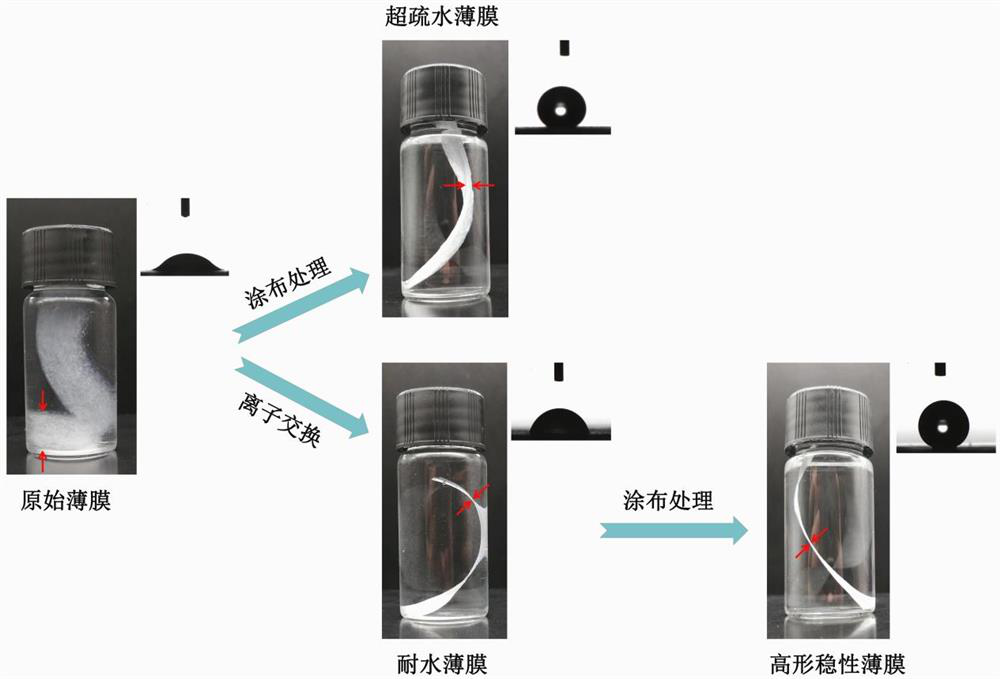

Cellulose-based transparent waterproof film with high dimensional stability and preparation method thereof

A cellulose-based, waterproof film technology, applied in the direction of coating, etc., can solve the problem of shape stability, can not prevent small volume water molecules from attacking layer by layer, to reduce energy consumption, reduce electrostatic repulsion, and improve moisture resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0045] (1) Using bleached hardwood pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO ) and 10wt% of dry pulp were weighed NaBr in a beaker, added distilled water to 100mL, and dissolved under magnetic stirring, stand-by. Transfer 200 g of bleached hardwood pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, th...

Embodiment 2

[0050] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0051] (1) Using bleached softwood pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO ) and 10wt% of dry pulp were weighed NaBr in a beaker, added distilled water to 100mL, and dissolved under magnetic stirring, stand-by. Transfer 200 g of bleached softwood pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, th...

Embodiment 3

[0056] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0057] (1) Using bamboo pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) and Weigh 10wt% of dry pulp NaBr into a beaker, add distilled water to 100mL, dissolve under magnetic stirring, and set aside. Transfer 200 g of bamboo pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, the reaction is complete. Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com