GaN-based Schottky diode and preparation method thereof

A Schottky diode, GaN-based technology, applied in diodes, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of limited improvement of field plate technology withstand voltage, device design and process difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

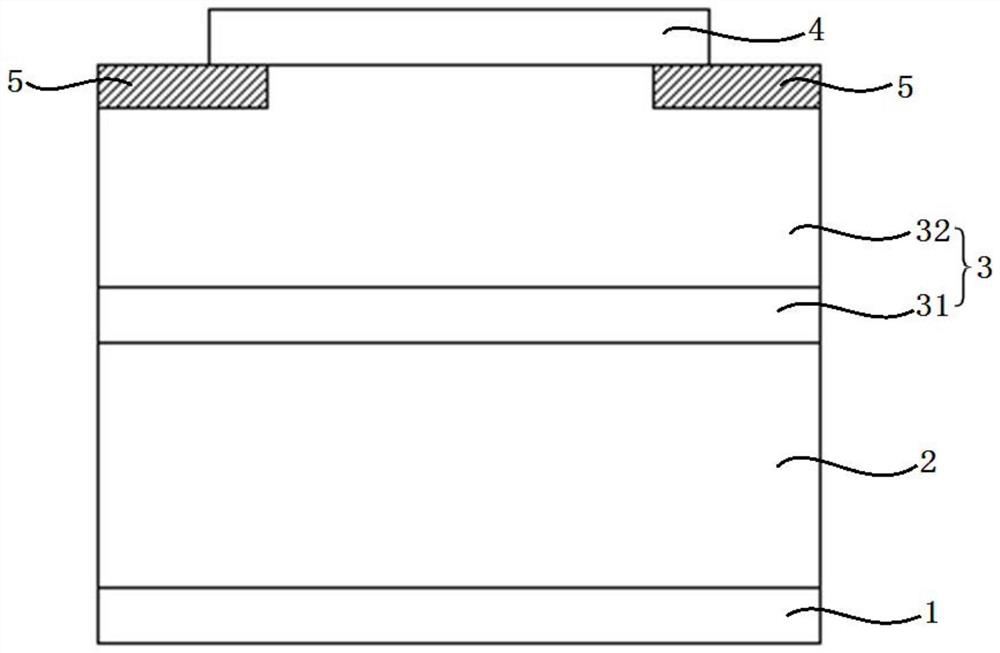

[0059] The present invention also provides a preparation method of the gallium nitride-based Schottky diode, including:

[0060] providing a substrate 2, and forming an n-type gallium nitride layer 3 on the substrate 2;

[0061] Forming a gallium oxide insulating layer 5 at the edge of both ends of the n-type gallium nitride layer 3 facing away from the substrate 2;

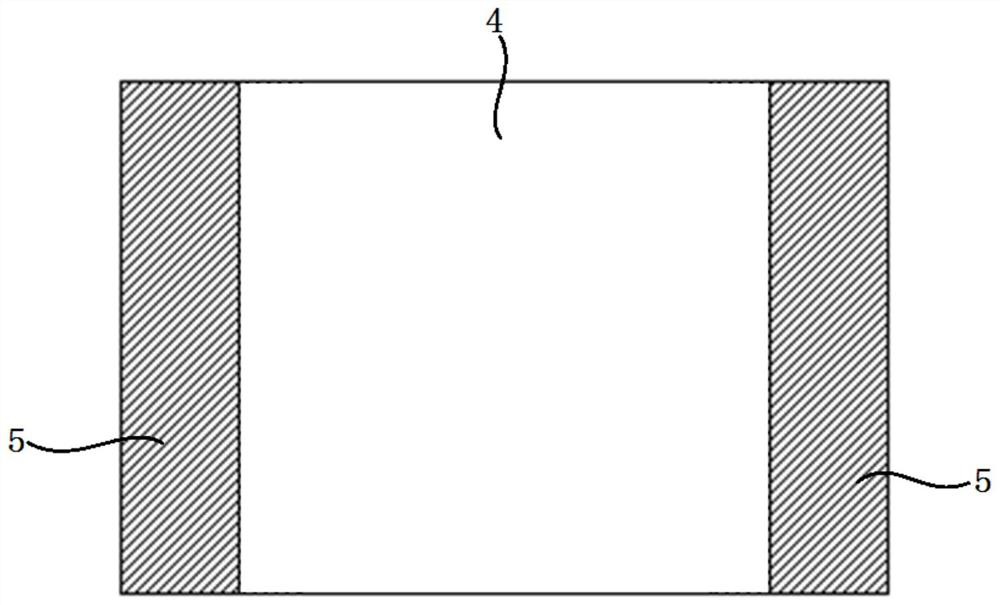

[0062] Forming a Schottky metal electrode 4 on the side of the n-type gallium nitride layer 3 away from the substrate 2 and at least partially covering the gallium oxide insulating layer 5;

[0063] An ohmic contact electrode 1 is formed on the side of the substrate 2 away from the n-type gallium nitride layer 3 .

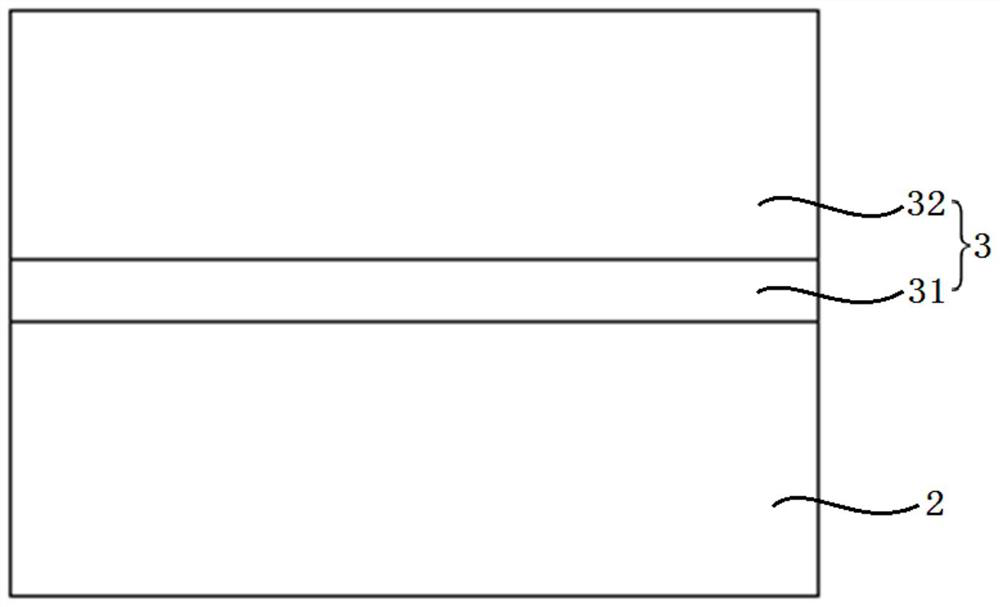

[0064] As an optional embodiment of the present invention, forming the n-type gallium nitride layer 3 on the substrate 2 includes:

[0065] A first n-type gallium nitride layer 31 and a second n-type gallium nitride layer 32 are sequentially formed on the substrate 2, and the doping concentration of...

Embodiment 1

[0075] This embodiment provides a method for preparing a GaN-based Schottky diode, the steps are as follows:

[0076] Step S1, prepare a substrate 2 (n-type GaN substrate polished on both sides), and sequentially grow a 2 μm first n-type gallium nitride layer 31 (n+ Type Si-doped GaN layer with a doping concentration of 2×10 18 cm -3 ) and the second n-type gallium nitride layer 32 of 8 μm (n-type Si-doped gallium nitride layer, the doping concentration is 6×10 15 cm -3 ), hydrosilane is used as Si dopant material, and the device structure that step S1 obtains is as image 3 shown;

[0077] In step S2, uniformly apply a layer of photoresist on the upper surface of the second n-type gallium nitride layer 32 to form a mask layer 6, and the device structure obtained in step S2 is as follows Figure 4 shown;

[0078] Step S3, remove the photoresist at both ends of the mask layer 6 by exposure and development, and form a gap at both ends of the mask layer 6, the gap exposes the...

Embodiment 2

[0087] This embodiment provides a method for preparing a GaN-based Schottky diode, the steps are as follows:

[0088] Step S1, prepare a substrate 2 (sapphire substrate), and sequentially grow a 5 μm first n-type GaN layer 31 (n+-type Si-doped nitride layer) on the substrate 2 by using a hydride vapor phase epitaxy (HVPE) process. Gallium layer, the doping concentration is 3×10 18 cm -3 ) and a second n-type gallium nitride layer 32 of 10 μm (n-type Si-doped gallium nitride layer, the doping concentration is 8×10 15 cm -3 ), hydrosilane is used as Si dopant material, and the device structure that step S1 obtains is as image 3 shown;

[0089] In step S2, uniformly apply a layer of photoresist on the upper surface of the second n-type gallium nitride layer 32 to form a mask layer 6, and the device structure obtained in step S2 is as follows Figure 4 shown;

[0090] Step S3, remove the photoresist at both ends of the mask layer 6 by exposure and development, and form a ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com