A kind of electrochemically prepared functionalized graphene flame retardant and its application

A flame retardant, graphene technology, applied in the chemical characteristics of fibers, the manufacture of fire-retardant and flame-retardant filaments, textiles and papermaking, etc., can solve the problems of non-compliance with green production, different material substrates, and cannot be completely restored, and achieve mechanical properties. Improve, improve the flame retardant performance, improve the effect of flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

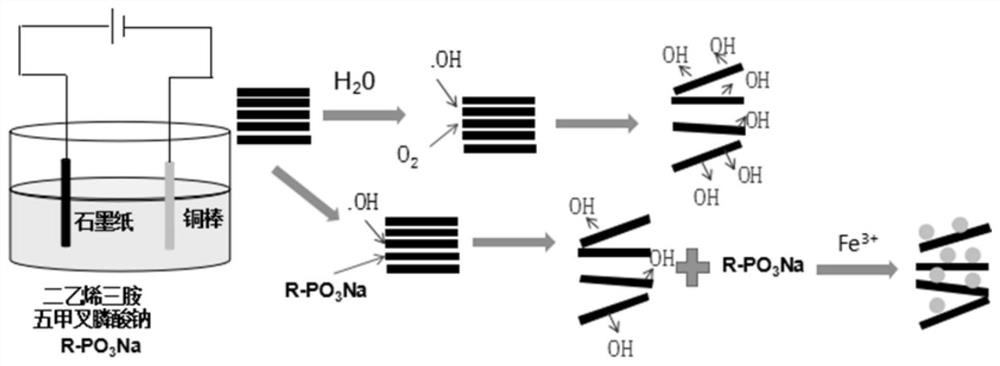

[0044] Embodiment 1: Preparation of functionalized graphene flame retardant

[0045]The 0.5mm graphite paper made of expanded graphite is used as the anode, the copper rod is used as the cathode, and 150ml of 0.2mol / L sodium diethylenetriaminepentamethylene phosphonate is used as the electrolyte, and a DC voltage of 5V is applied for electrolysis for 6h, filtered, Wash and dry to obtain the graphene modified by sodium diethylenetriaminepentamethylene phosphate, get 1g of graphene modified by sodium diethylenetriaminepentamethylene phosphate and add it to 0.5mol / L ferric chloride aqueous solution (30mL) while stirring After ultrasonication for 3 hours, it was filtered, and the obtained precipitate was dried to obtain a functionalized graphene flame retardant.

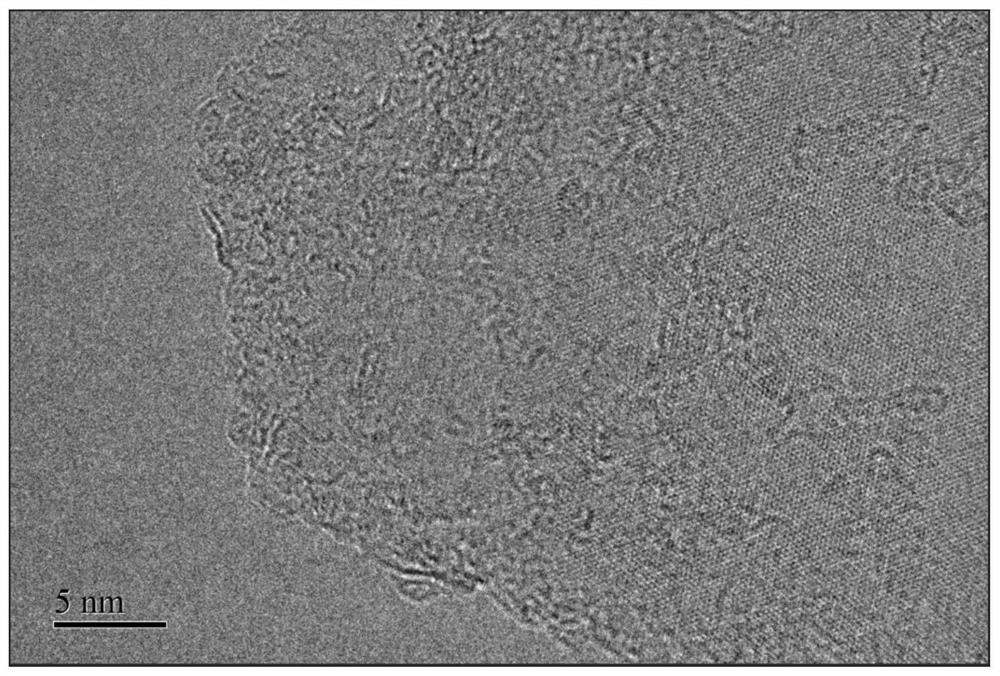

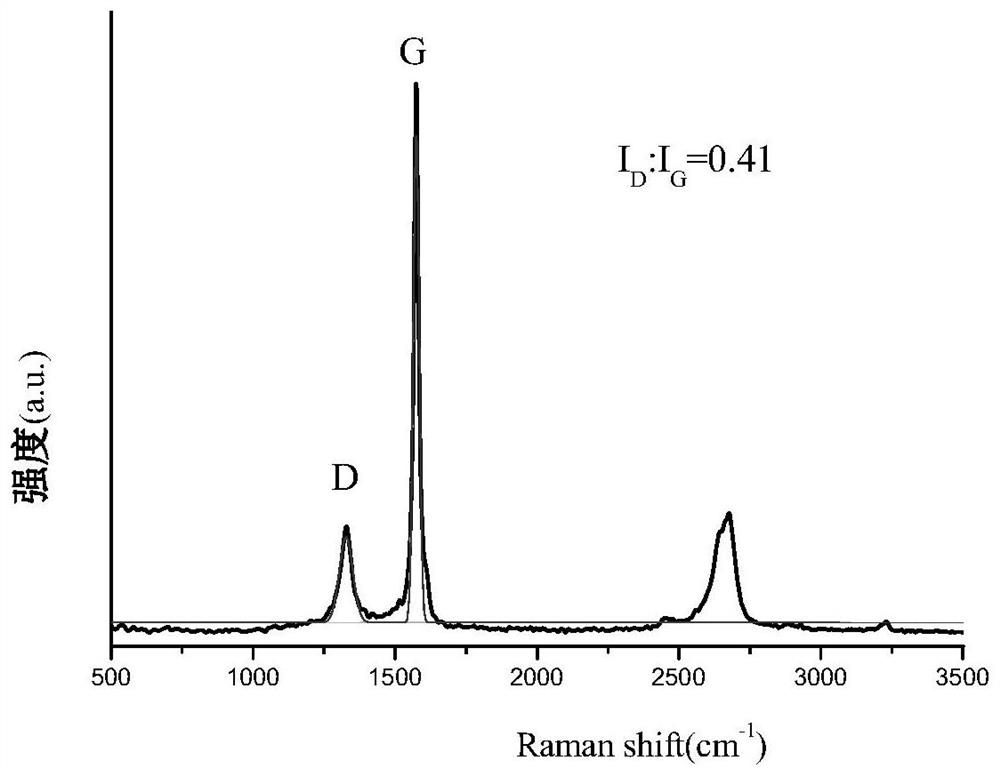

[0046] High-magnification transmission electron microscopy of the prepared functionalized graphene flame retardant as figure 2 shown. It can be seen from the high-power transmission electron microscope analysis that t...

Embodiment 2

[0049] Embodiment 2: the preparation of functionalized graphene flame retardant

[0050] The 0.3mm graphite paper made of flake graphite is used as the anode, the copper rod is used as the cathode, and 150ml of 0.5mol / L sodium diethylenetriaminepentamethylene phosphonate is used as the electrolyte, and a DC voltage of 5V is applied for electrolysis for 6h, filtered, Wash and dry to obtain graphene modified by sodium diethylenetriaminepentamethylene phosphate, take 1g of graphene modified by sodium diethylenetriaminepentamethylene phosphate and add it to 0.5mol / L ferric chloride aqueous solution while stirring and ultrasonically for 3h , filtered, and the resulting precipitate was dried to obtain a functionalized graphene flame retardant.

[0051] The number of layers of the graphene of gained is 3 layers, 1 D / I G The value is 0.68, and the defect is relatively small.

Embodiment 3

[0052] Embodiment 3: the preparation of functionalized graphene flame retardant

[0053] The 1mm graphite paper made of highly oriented graphite is used as the anode, the copper rod is used as the cathode, and 150ml of 0.1mol / L sodium diethylenetriaminepentamethylene phosphonate is used as the electrolyte, and a DC voltage of 5V is applied for electrolysis for 6h, filtered, Wash and dry to obtain graphene modified by sodium diethylenetriaminepentamethylene phosphate, take 1g of graphene modified by sodium diethylenetriaminepentamethylene phosphate and add it to 0.5mol / L ferric chloride aqueous solution while stirring and ultrasonically for 3h , filtered, and the resulting precipitate was dried to obtain a functionalized graphene flame retardant.

[0054] The number of layers of the graphene of gained is 3 layers, 1 D / I G The value is 0.71, and the defect is relatively small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com