Flame-retardant polyurethane adhesive and preparation method thereof

A polyurethane adhesive, flame-retardant technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems such as leakage, glass bricks and adhesive quality that cannot meet technical requirements, and achieve the preparation method Simple, improved anti-corrosion durability and safety, and the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

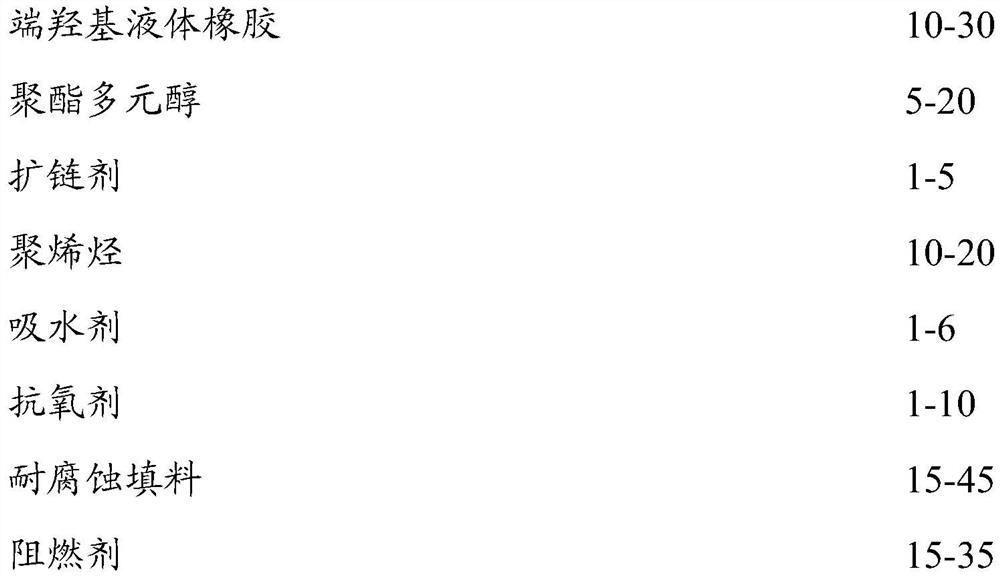

Method used

Image

Examples

Embodiment 1

[0031] Flame-retardant polyurethane adhesive includes A component and B component, and the preparation method is as follows:

[0032] 30kg of hydroxyl-terminated polybutadiene (HTPBШ type, Liming Institute of Chemical Industry, hydroxyl value 38mgKOH / g, molecular weight 1800-3500) and 10kg of quartz powder (604, Sibelco Mining Co., Ltd., with an average particle size (D50) of 15μm ) into the mixing device for 15 minutes, add 3kg trishydroxymethyl phosphine oxide, 10kg antimony trioxide and 10kg decabromodiphenylethane, 2kg antioxidant Irganox 1010, 2kg chain extender Span80 (Guangdong Runhua Chemical Co., Ltd. , hydroxyl value 200mgKOH / g), 10kg polyisobutylene (PB4000, Daelim, South Korea, molecular weight 4000) were mixed for 15 minutes to obtain a premix; 7kg corrosion-resistant filler barium sulfate (XLT-3, Guizhou Xinli Tinto Mining Co., Ltd. , 600 mesh) mixed with 15kg polycaprolactone diol (L330AL, Nippon Chemical Industry Co., Ltd. Daicel, 3000 molecular weight, hydroxy...

Embodiment 2

[0034] Flame-retardant polyurethane adhesive includes A component and B component, and the preparation method is as follows:

[0035]Mix 10kg of hydroxyl-terminated polybutadiene (HTPBШ type, Liming Institute of Chemical Industry, hydroxyl value 38mgKOH / g, molecular weight 1800-3500) and 15kg of silica powder (604, Sibelco Mining Co., Ltd., particle size (D50) is 15μm) Put into stirring device and mix for 15 minutes, add flame retardant 5kg trishydroxymethyl phosphine oxide, 6kg antimony trioxide and 14kg decabromodiphenylethane, 2kg antioxidant Irganox 1010, 2kg Span80 (Guangdong Runhua Chemical Co., Ltd., Hydroxyl value 200mgKOH / g), 3kg 1,4-butanediol (BASF), 5kg EPDM rubber (EV-30, Dongguan Junsong Plastic, molecular weight 45000, dynamic viscosity value at 25°C 200000cps), 10kg polyisobutylene (Jilin Petrochemical, molecular weight 3000) mixed again for 15 minutes to obtain a premix; 20kg microsilica powder (604, Sibelco Mining Co., Ltd.) and 5kg polycaprolactone glycol (C...

Embodiment 3

[0037] Flame-retardant polyurethane adhesive includes A component and B component, and the preparation method is as follows:

[0038] 25kg of hydroxyl-terminated polybutadiene (HTPB Poly bd R-45HT, Japan Idemitsu Kosan Co., Ltd., molecular weight 2800, hydroxyl value 46mgKOH / g) and 15kg of silicon micropowder (604, Sibelco Mining Co., Ltd., particle size (D50 ) is 15 μm) was put into a stirring device and mixed for 15 minutes, adding flame retardant 7kg antimony trioxide and 13kg decabromodiphenylethane, 3kg antioxidant Irganox1010, 1kg chain extender 1,4-butanediol (Tianjin Zhonghe Shengtai Chemical Co., Ltd.), 2kg Span80 (Guangdong Runhua Chemical Co., Ltd., hydroxyl value 200mgKOH / g), 5kg EPDM rubber (EV-30, Dongguan Junsong Plastic, molecular weight 45000, 25℃ viscosity value 200000cps), 5kg poly Isobutylene (PB2400, produced in Korea Daelim, molecular weight 2400, viscosity 4500cps at 100°C) was mixed for 15 minutes to obtain the premix; With 8kg polycaprolactone diol (C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com