Diamond-based gallium nitride composite wafer and bonding preparation method thereof

A technology of diamond and gallium nitride, which is applied in the manufacture of microwave radio frequency devices and power electronic devices, the field of diamond-based gallium nitride composite wafer and its bonding preparation, and can solve wafer warpage, gallium nitride and diamond lattice constant Differences, difficulties in growing high-quality gallium nitride or diamond epitaxial layers, etc., to reduce pollution and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

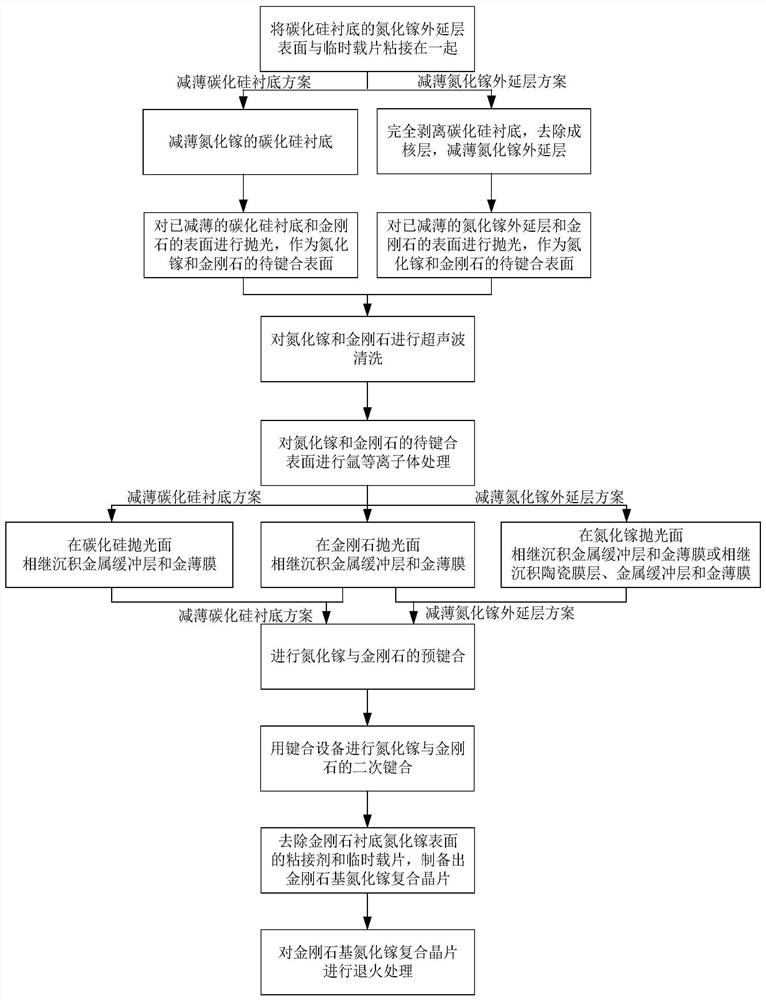

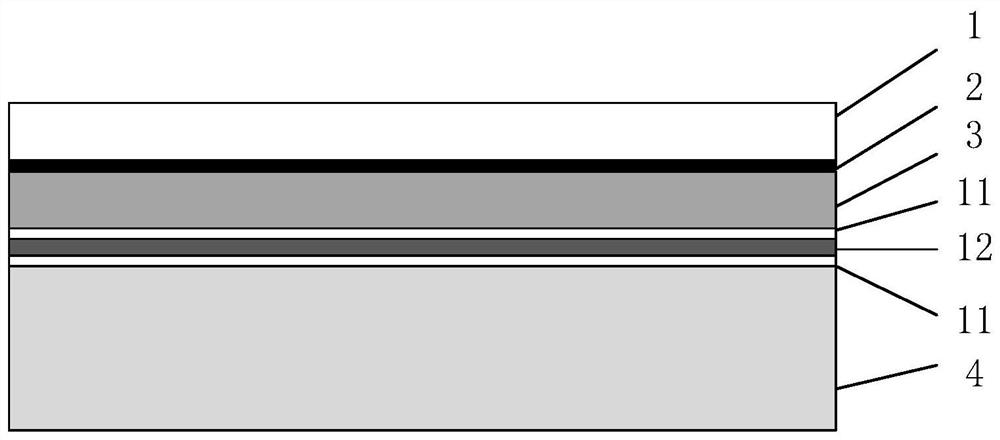

[0054] see figure 1 and figure 2 , the GaN-on-diamond composite wafer prepared by the present invention has the structure of GaN / nucleation layer / silicon carbide (5-80 microns) / metal buffer layer / gold film / metal buffer layer / diamond, and the specific preparation method includes the following step:

[0055] 1) bonding the surface of the gallium nitride epitaxial layer of the silicon carbide substrate gallium nitride to the silicon wafer (temporary carrier) with photoresist;

[0056] 2) The silicon carbide substrate is thinned to 40 microns by mechanical grinding;

[0057] 3) Carrying out surface polishing on the silicon carbide substrate and the diamond, so that the roughness of the polished surface of the silicon carbide substrate and the diamond is lower than 2 nanometers;

[0058] 4) Ultrasonic cleaning of gallium nitride and diamond with acetone, ethanol and deionized water successively;

[0059] 5) Put the gallium nitride and diamond into the sputter coater, use the p...

Embodiment 2

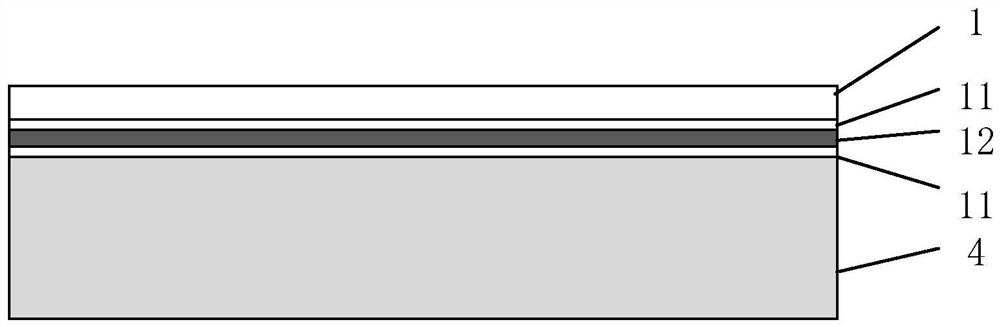

[0066] see figure 1 and image 3 The gallium nitride-on-diamond composite wafer prepared by the present invention has a structure of gallium nitride (1-3 microns) / metal buffer layer / gold film / metal buffer layer / diamond, and the specific preparation method includes the following steps:

[0067] 1) Using benzocyclobutene (BCB) to bond the surface of the gallium nitride epitaxial layer of the silicon carbide substrate gallium nitride to the silicon carbide wafer (temporary carrier);

[0068] 2) The silicon carbide substrate is thinned to 30 microns by mechanical grinding, and then the remaining silicon carbide substrate is etched away by inductively coupled plasma etching, the nucleation layer is removed, and the gallium nitride epitaxial layer is thinned to 2 microns;

[0069] 3) Surface polishing of the epitaxial layer of gallium nitride and diamond, so that the roughness of the polished surface of gallium nitride and diamond is lower than 2 nanometers;

[0070] 4) Ultrasoni...

Embodiment 3

[0078] see figure 1 and Figure 4 The gallium nitride-on-diamond composite wafer prepared in the present invention has a structure of gallium nitride (1-3 microns) / ceramic film layer / metal buffer layer / gold film / metal buffer layer / diamond, and the specific preparation method includes the following steps:

[0079] 1) Using 502 glue to bond the surface of the gallium nitride epitaxial layer of the silicon carbide substrate gallium nitride to the quartz plate (temporary carrier);

[0080] 2) The silicon carbide substrate is thinned to 50 microns by mechanical grinding, and then the remaining silicon carbide substrate is etched away by inductively coupled plasma etching, the nucleation layer is removed, and the gallium nitride epitaxial layer is thinned to 3 microns;

[0081] 3) Surface polishing of the epitaxial layer of gallium nitride and diamond, so that the roughness of the polished surface of gallium nitride and diamond is lower than 2 nanometers;

[0082] 4) Ultrasonic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com