Nickel-coated graphite sealing coating on surface of cast-iron workpiece, and preparation method of nickel-coated graphite sealing coating

A nickel-coated graphite and sealing coating technology is applied in the field of thermal spraying nickel-coated graphite sealing coating on cast iron surface and its preparation. Dense, low cost, well combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (2) Preparation of bonding layer. The selected NiAl wire has a diameter of 1-4µm, and the bonding layer NiAl coating is prepared on the surface of the base material by arc spraying method. The parameters of the arc spraying process include: spraying current 120-180A; spraying voltage 25-35V; atomization The air pressure is 0.4-0.8MPa, and the spraying distance is 100-180mm.

[0030] (3) Preparation of nickel-coated graphite surface layer. The particle size of the nickel-coated graphite powder selected for the preparation of the nickel-coated graphite coating is 90-150 μm, and the nickel-coated graphite powder is sprayed on the substrate with a bonding bottom layer by using the flame spraying method to obtain NiAl / nickel-coated Graphite double layer structure abradable sealing coating system. Among them, the parameters of flame spraying process include: oxygen pressure: 0.5~1.0MPa; oxygen flow: 70~100L / h; acetylene pressure: 0.05~0.20MPa; acetylene flow: 30~70L / h; powd...

Embodiment 1

[0033] A NiAl / nickel-coated graphite double-layer coating structure is prepared on the cast iron substrate, the inner layer is: bonding layer, NiAl layer; the surface layer: nickel-coated graphite layer.

[0034] The steps of coating preparation are as follows:

[0035]Step 1: Perform sandblasting pretreatment on the surface of the cast iron substrate, and the sandblasting pressure is 0.4MPa;

[0036] Step 2: Using a wire arc spraying system, spray the above-mentioned NiAl wire with a suitable particle size on the pretreated substrate. The spraying process parameters are shown in Table 1, and the thickness of the coating is 50-70 μm;

[0037] Table 1 shows the process parameters of arc spraying NiAl coating:

[0038]

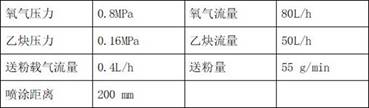

[0039] Step 3: Using a flame spraying system, spray the above-mentioned nickel-coated graphite powder with a suitable particle size on the base material with a bonding layer NiAl layer, and the spraying process parameters are shown in Table 2;

[0040] Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com