Easy-to-adhere nylon film and preparation method thereof, and nylon-based composite film and preparation method thereof

A nylon film and bonding technology, applied in the field of packaging materials, can solve problems such as insufficient bonding and achieve the effect of good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

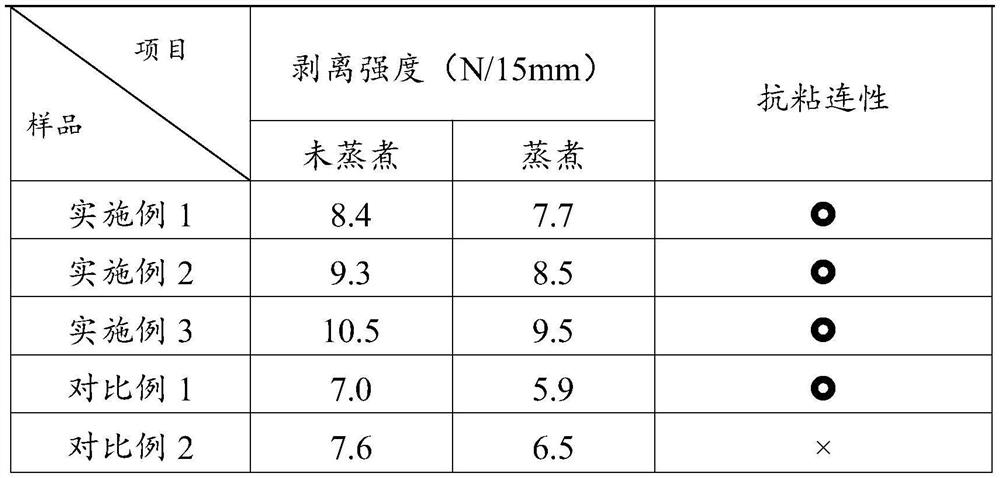

Examples

preparation example Construction

[0053] The present invention also provides a preparation method for the easy-adhesive nylon film described in the above technical solution, comprising the following steps:

[0054] Mixing nylon resin, slip agent, blocking agent, easy-bonding functional material and antistatic agent, melting and extruding through an extruder to obtain melt raw materials for the first surface layer and the second surface layer;

[0055] Melting and extruding the nylon resin through an extruder to obtain the melt raw material of the core layer;

[0056] Co-extruding the melt raw materials of the first surface layer and the second surface layer and the melt raw materials of the core layer, casting them on the surface of the chilled roll, and obtaining the nylon substrate layer after plasma treatment;

[0057] Mix the modified water-based hydroxyl acrylic resin, nano-silica grafted hyperbranched polymer, ethylene maleic anhydride copolymer, solvent, cross-linking agent and slip agent, and carry out...

Embodiment 1

[0081] The mass percentage content is: 94.2% nylon 6 resin, 0.2% oleic acid amide, 0.5% magnesium carbonate (particle size is 0.005 ~ 1.2 μm), 5% ethylene acrylic acid copolymer and 0.1% trishydroxyethyl methyl quaternary ammonium Methylsulfate is mixed, melted and extruded by an extruder to obtain the melt raw material of the first surface layer;

[0082] The mass percentage content is: 88.2% nylon 11 resin, 0.5% erucamide, 0.8% sodium silicate (particle size is 0.008 ~ 1.3 μm), 10% ionized ethylene methacrylic acid copolymer and 0.5% graphene mixed , melt and extrude through an extruder to obtain the melt raw material of the second surface layer;

[0083] Melting and extruding nylon 6 resin through an extruder to obtain the melt raw material of the core layer;

[0084] Cast the melt raw materials of the first surface layer and the second surface layer and the melt raw material of the core layer through a T-die to the surface of a chilled roll at a temperature of 30°C, and t...

Embodiment 2

[0090] The difference between this embodiment and embodiment 1 is:

[0091] The mass percentage content is: 87.5% nylon 6 / 12 resin, 1% ethylene bis stearic acid amide, 0.5% talcum powder (particle size is 0.01 ~ 1.5 μm), 10% ionized ethylene methacrylic acid copolymer Mix with 1% stearamidopropyl dimethyl-β-hydroxyethylammonium dihydrogen phosphate, melt and extrude through an extruder to obtain the melt raw material of the first surface layer;

[0092] The mass percentage content is: 87.5% nylon 610 resin, 1% silicone oil, 0.5% diatomaceous earth (particle size is 0.005 ~ 1.8 μm), 10% ethylene-methyl acrylate copolymer and 1% polyol fatty acid ester Mixing, melting and extruding through an extruder to obtain the melt raw material of the second surface layer;

[0093] Melting and extruding nylon 6 / 66 resin through an extruder to obtain the melt raw material of the core layer;

[0094] The mass parts are 50 parts of organosiloxane modified hydroxyacrylic resin, 20 parts of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com