Nitrogen-doped three-dimensional porous graphene-based electrode material as well as preparation method and application thereof

A three-dimensional porous, graphene-based technology, applied in the field of electrochemistry, can solve problems such as hindering the application of graphene-based electrochemical sensors, affecting sensor performance, easy agglomeration and overlapping, and achieving good application potential, short response time, and long-term stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a nitrogen-doped three-dimensional porous graphene-based electrode material, comprising the following steps:

[0035] 1) Take 50mL graphene oxide (2mg / mL) solution, according to the volume ratio of graphene oxide solution and hydrogen peroxide solution 15:1, add hydrogen peroxide solution (30wt.%), ultrasonic treatment for 15min, and then graphene oxide The mixed solution with hydrogen peroxide was transferred to a round-bottomed flask, and reacted at 95°C for 5 h; the resulting product was immersed in ultrapure water and dialyzed for 4 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen, and Continue freeze-drying in a freeze dryer for 10 hours to obtain a three-dimensional porous graphene oxide solid;

[0036] 2) Take 70 mg of the three-dimensional porous graphene oxide solid obtained above and dissolve it in 70 mL of ultrapure water, then add urea according to the mass ratio of urea solid to three-dim...

Embodiment 2

[0039] A preparation method of a nitrogen-doped three-dimensional porous graphene-based electrode material, comprising the following steps:

[0040]1) Take 50mL graphene oxide (2mg / mL) solution, according to the volume ratio of graphene oxide solution and hydrogen peroxide solution 12:1, add hydrogen peroxide solution (20wt.%), ultrasonic treatment for 20min, and then the graphene oxide The mixed solution with hydrogen peroxide was transferred to a round-bottomed flask, and reacted at 100°C for 3 h; the resulting product was immersed in ultrapure water and dialyzed for 5 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen, and Continue freeze-drying in a freeze dryer for 12 hours to obtain a three-dimensional porous graphene oxide solid;

[0041] 2) Take 70 mg of the three-dimensional porous graphene oxide solid obtained above and dissolve it in 50 mL of ultrapure water, then add urea according to the mass ratio of urea solid to three...

Embodiment 3

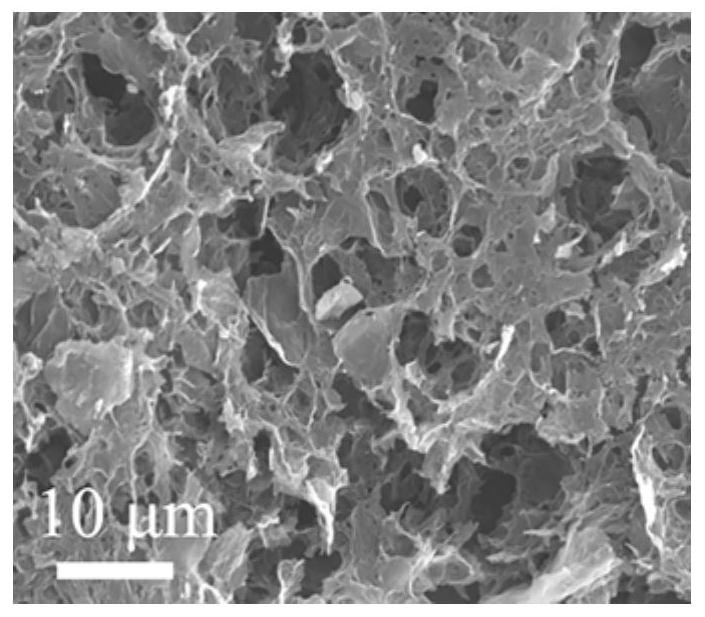

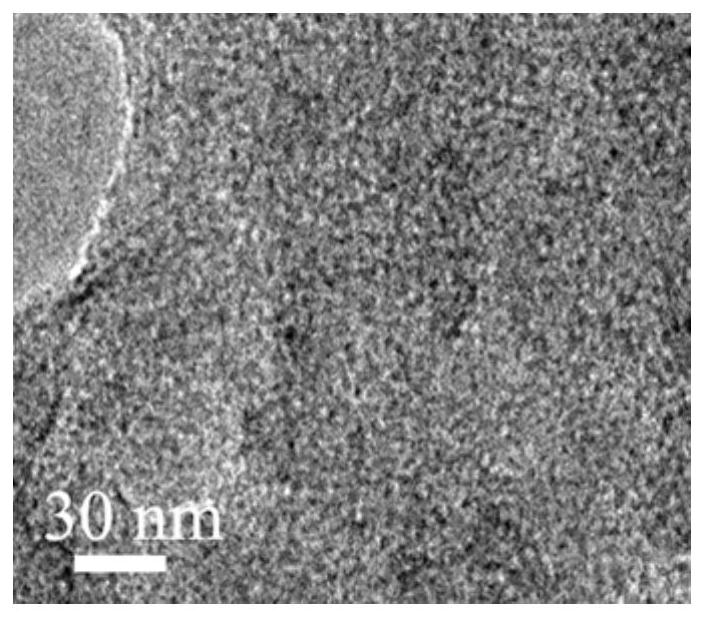

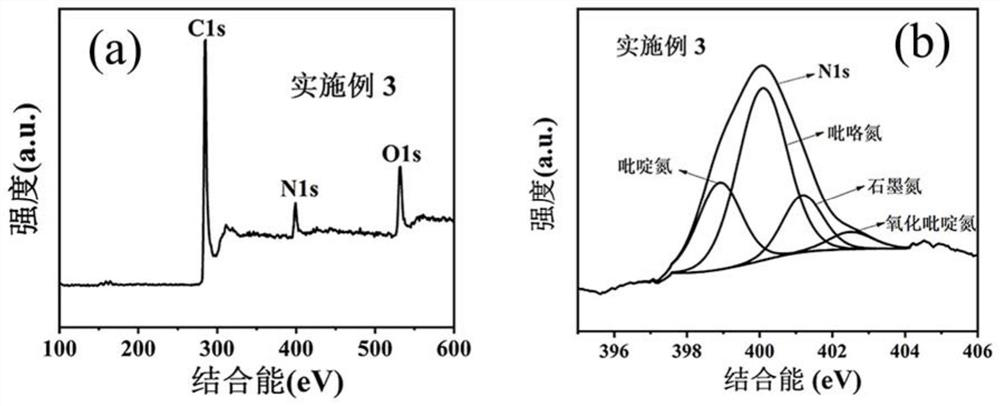

[0044] A preparation method of a nitrogen-doped three-dimensional porous graphene-based electrode material, comprising the following steps:

[0045] 1) Take 50mL graphene oxide (2mg / mL) solution, according to the volume ratio of graphene oxide solution and hydrogen peroxide solution 10:1, add hydrogen peroxide solution (40wt.%), ultrasonic treatment for 15min, and then graphene oxide The mixed solution with hydrogen peroxide was transferred to a round-bottomed flask, and reacted at 100°C for 3.5 hours; the resulting product was immersed in ultrapure water and dialyzed for 6 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen. And continue to freeze-dry for 12 hours in a freeze dryer to obtain a three-dimensional porous graphene oxide solid;

[0046] 2) Dissolve 70 mg of the three-dimensional porous graphene oxide solid obtained above in 35 mL of ultrapure water, add urea at a mass ratio of 50:1 between urea solid and three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com