A kind of MS sealant with insect repellent and anti-ultraviolet aging and preparation method

An MS sealant, anti-ultraviolet technology, applied in the direction of adhesives, polyether adhesives, adhesive additives, etc., can solve the problems of reducing the tightness of MS sealants, accelerating the aging of colloids, reducing the viscosity of MS sealants, etc. Good physical and mechanical properties, prolong the use time, reduce the effect of aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

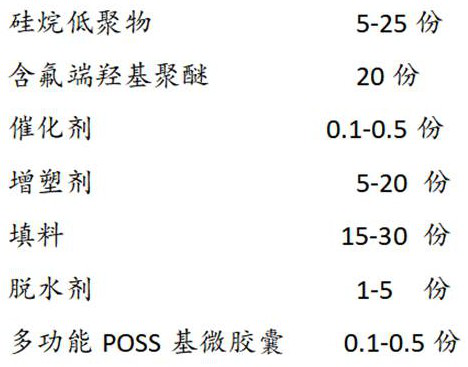

[0033] A preparation method of MS sealant with insect repellent and anti-ultraviolet aging, the preparation method comprises the following steps:

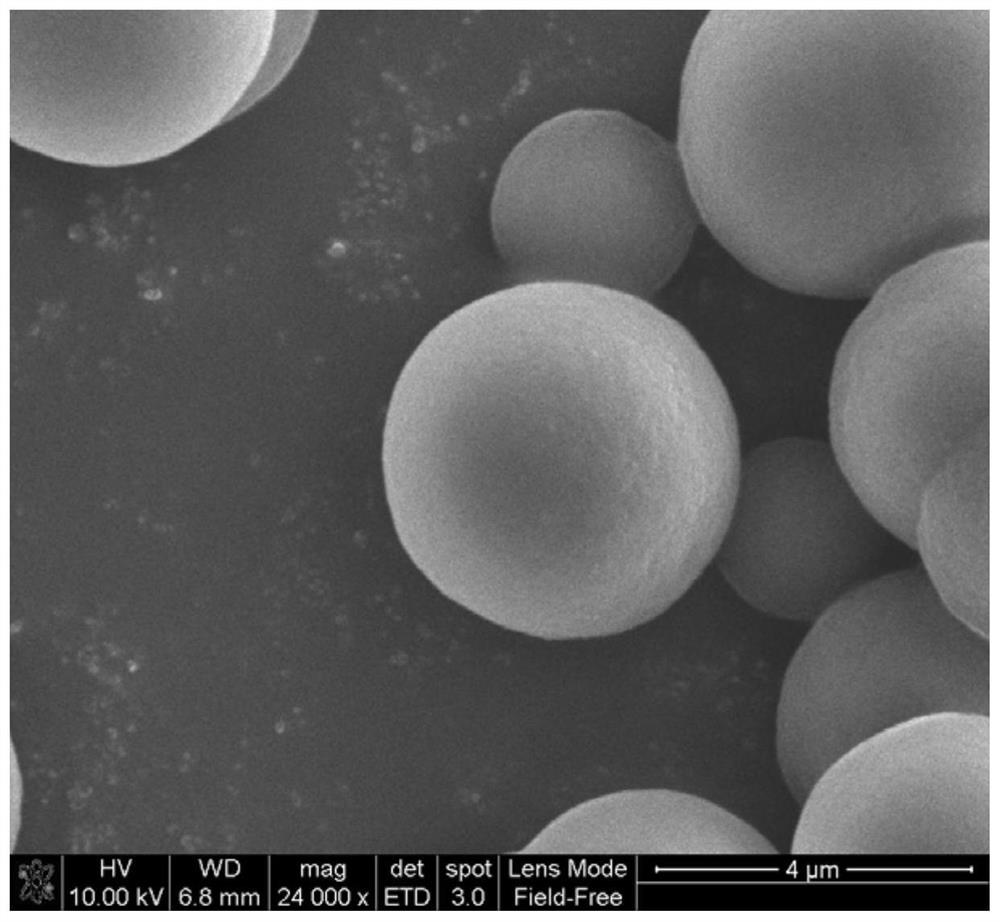

[0034] 1) Mix 0.5g of styrene, 0.5g of methyl methacrylate, 1g of citronella essential oil, 0.5g of 2-[3-(2-benzotriazol-2-yl)-4-hydroxyphenyl]methacrylic acid Ethyl ester, 0.5g ammonium octachloride propyl silsesquioxane, 0.1g alkylphenol polyoxyethylene ether, 0.1g sodium dodecylbenzenesulfonate, 0.1g sodium bicarbonate and 1ml acrylic acid dissolved in 80ml distilled water Then, the mixture was emulsified at a speed of 300rpm / min for 15 minutes. Finally, the obtained emulsion was poured into a 500ml four-necked flask, and argon gas was introduced for 30min. After the temperature was raised to 60°C, 5ml of 1wt% The initiator ammonium persulfate solution was added until the dropwise addition was completed, and the polymer containing citronella essential oil was obtained after continuous stirring and reaction for 3 hours.

[0035]...

Embodiment 2

[0041] A preparation method of MS sealant with insect repellent and anti-ultraviolet aging, the preparation method comprises the following steps:

[0042]1) 1 g of styrene, 1 g of methyl methacrylate, 2 g of eucalyptus essential oil, 1 g of 2-[3-(2-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl methacrylate, 1g octaammonium propyl silsesquioxane, 0.5g alkylphenol polyoxyethylene ether, 0.1g sodium dodecylbenzenesulfonate, 0.5g sodium bicarbonate and 2ml acrylic acid were dissolved in 80ml distilled water, and then The mixture was emulsified at a speed of 300rpm / min for 20 minutes. Finally, the obtained emulsion was poured into a 500ml four-necked flask, and argon was introduced for 30min. After the temperature was raised to 70°C, 15ml of 1wt% initiator was added dropwise. Ammonium sulfate solution, until the dropwise addition is completed, and then continue stirring and reacting for 3 hours to obtain a polymer containing eucalyptus essential oil.

[0043] 2) Dissolve 0.5g of vinylt...

Embodiment 3

[0049] A preparation method of MS sealant with insect repellent and anti-ultraviolet aging, the preparation method comprises the following steps:

[0050] 1) 1.5g of styrene, 1.5g of methyl methacrylate, 3g of clove essential oil, 1.5g of 2-[3-(2-benzotriazol-2-yl)-4-hydroxyphenyl]methacrylate ethyl Ester, 1.5g ammonium octachloride propyl silsesquioxane, 0.8g alkylphenol polyoxyethylene ether, 0.2g sodium dodecylbenzenesulfonate, 0.8g sodium bicarbonate and 4ml acrylic acid dissolved in 100ml distilled water , and then the mixture was emulsified at a speed of 400rpm / min for 20 minutes. Finally, the obtained emulsion was poured into a 500ml four-neck flask, and argon was introduced for 35min. After heating to 70°C, 10ml of 1.5wt% was added dropwise. The initiator ammonium persulfate solution was obtained until the dropwise addition was completed, and the polymer containing clove essential oil was obtained after continuous stirring and reaction for 3.5 hours.

[0051] 2) Disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com