Adhesive self-repairing hemostatic sponge and preparation method thereof

A hemostatic sponge and self-repairing technology, which can be used in medical formulations, surgery, drug delivery, etc., can solve the problems of inability to stimulate the endogenous hemostatic process and poor hemostatic effect, and achieve the goal of accelerating hemostatic efficiency, preventing displacement, and increasing swelling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

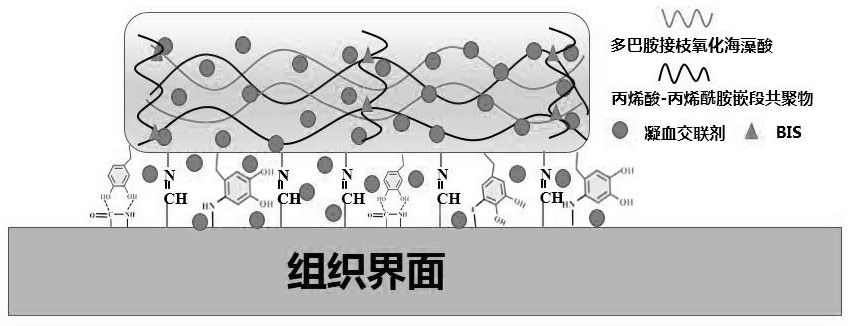

Method used

Image

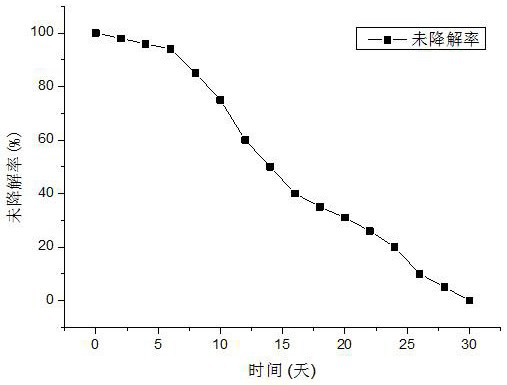

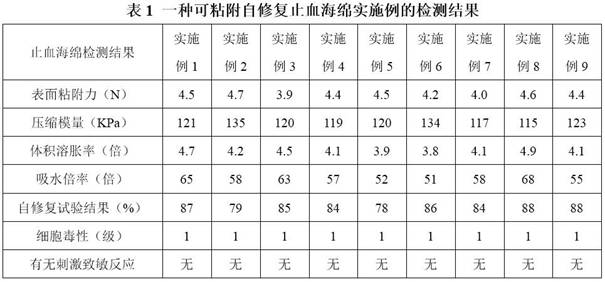

Examples

Embodiment 1

[0054] Example 1: 2.5% dopamine was grafted with oxidized alginic acid (85% oxidation degree, 15% dopamine grafting rate, and 300 mPa·s viscosity), 30% acrylamide, 13% acrylic acid, 0.015% N , N'-methylenebisacrylamide is added to purified water, stirred at 100-200rpm until it is completely dissolved, then sodium hydroxide solution is added dropwise to neutrality, 1.2% ammonium persulfate, 0.5% sodium bisulfite, 0.4 % calcium chloride, stirred evenly at 100-200rpm, and reacted at 60°C for 3h under the protection of nitrogen to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze dryer at -50°C for 4 hours, and vacuumed after the end,...

Embodiment 2

[0055] Example 2 Graft oxidized alginic acid with a mass fraction of 3.5% dopamine (oxidation degree is 80%, dopamine grafting rate is 10%, viscosity is 200mPa·s), 20% acrylamide, 20% acrylic acid, 0.01% N , Add N'-methylenebisacrylamide to purified water, stir at 100-200rpm until completely dissolved, add sodium hydroxide solution and disodium hydrogen phosphate solution to neutrality, add 1.1% ammonium persulfate, 0.5% Sodium bisulfite, 0.4% calcium sulfate, stirred evenly at 100-200rpm, and reacted at 60°C for 3h under the protection of nitrogen to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze dryer at -50°C for 4 hours, an...

Embodiment 3

[0056] Example 3 Graft oxidized alginic acid with a mass fraction of 1.5% of dopamine (90% oxidation degree, 20% dopamine grafting rate, and 500 mPa·s viscosity), 25% acrylamide, 13% acrylic acid, 0.02% N , N'-methylenebisacrylamide is added to purified water, stirred at 100-200rpm until it is completely dissolved, then sodium hydroxide solution and sodium bicarbonate solution are added dropwise to neutrality, 1.0% ammonium persulfate, 0.5% sulfite Sodium bisulfate, 0.5% calcium carbonate, stirred evenly at 100-200rpm, and reacted at 60°C for 3h under the protection of nitrogen to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com