Polymer-based composite medium with ferromagnetic anisotropy and preparation method thereof

An anisotropic, composite medium technology, applied in the field of preparation of multiferroic composite medium, can solve problems such as difficult adjustment and control, harsh growth conditions, restrictions, etc., and achieve the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] A method for preparing a polymer-based composite medium with ferromagnetic anisotropy, comprising the steps of:

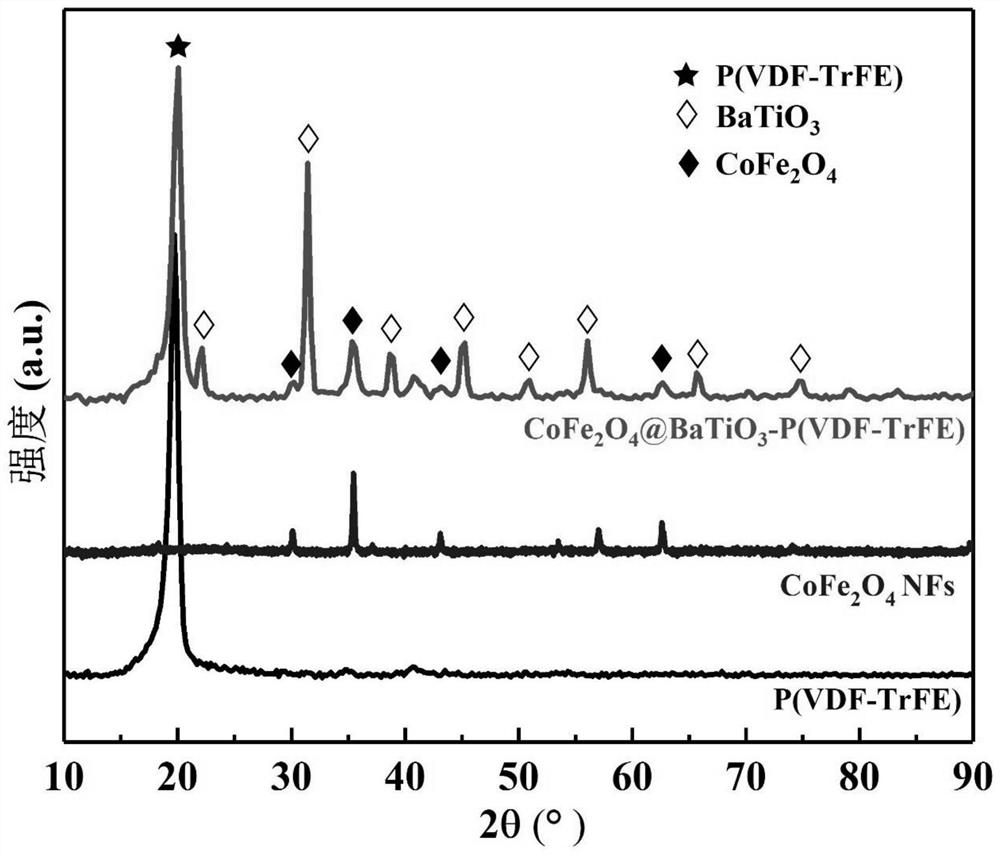

[0050] Step a, preparation of CoFe 2 o 4 Nanofibers;

[0051] Step b, preparation of core-shell structure CoFe 2 o 4 @BaTiO 3 Nanofibers;

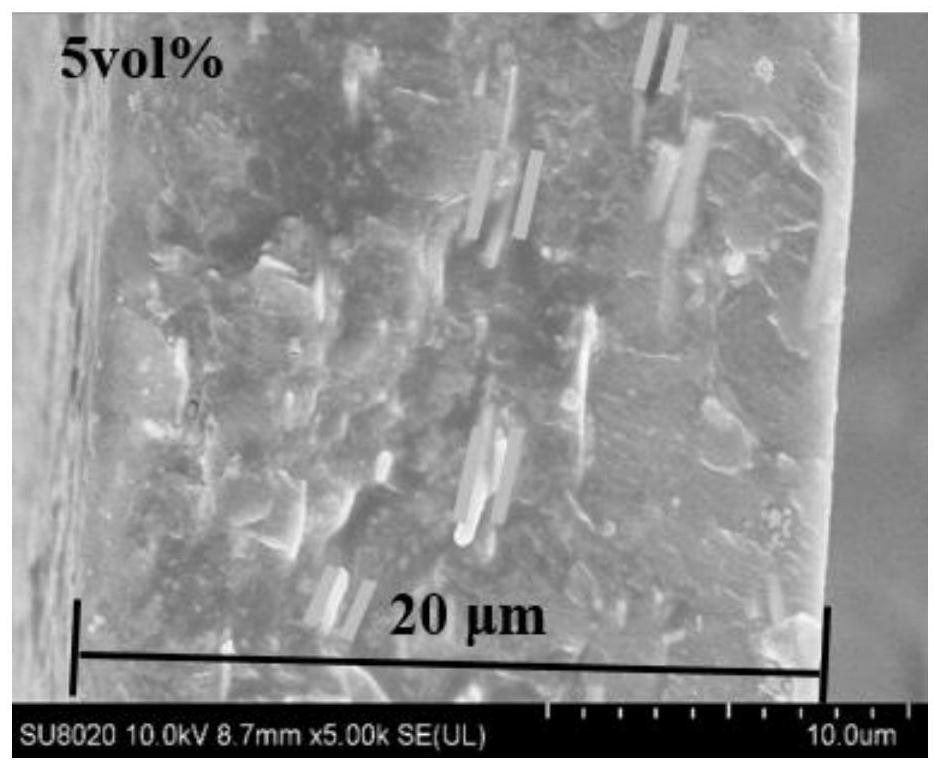

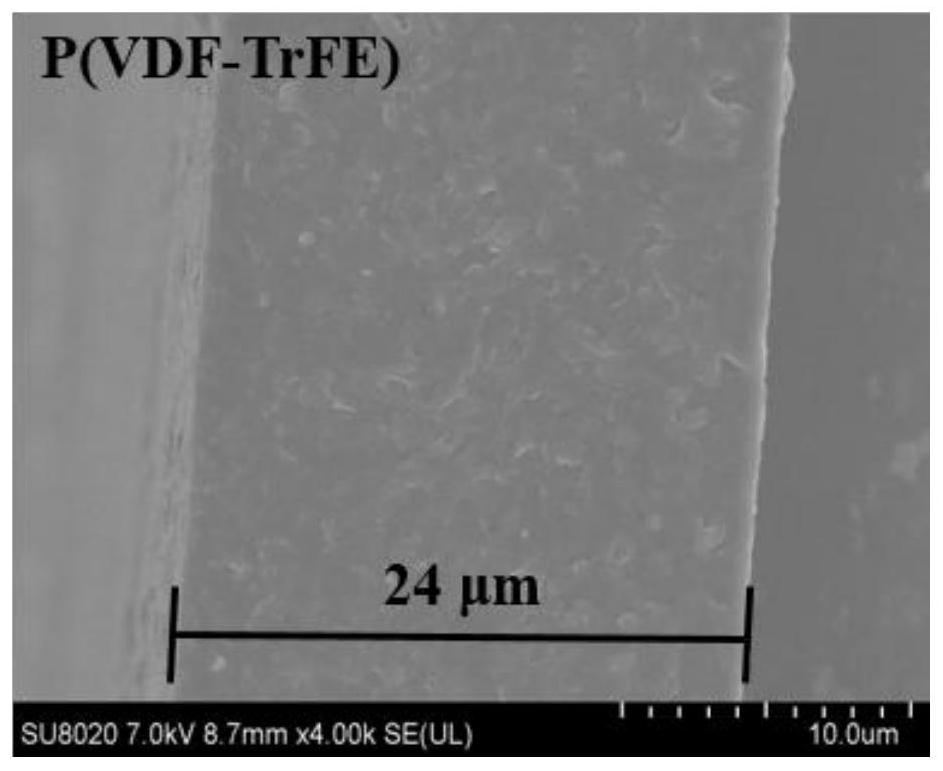

[0052] Step c, preparation of CoFe 2 o 4 @BaTiO 3 -P(VDF-TrFE) based composite medium;

[0053] Step d, preparing a polymer-based composite medium with ferromagnetic anisotropy.

[0054] A method for preparing a polymer-based composite medium with ferromagnetic anisotropy described in this embodiment, in step a, CoFe 2 o 4 The preparation method of nanofiber comprises the steps:

[0055] Step a1, weighing cobalt hexahydrate, ferric nitrate nonahydrate, and citric acid of a certain quality respectively according to the ratio of the amount of substances, and set aside;

[0056] Step a2, adding cobalt pinate hexahydrate and ferric nitrate nonahydrate weighed in step a1 into the ethanol solution, stirring evenly...

specific Embodiment approach 2

[0081] A method for preparing a polymer-based composite medium with ferromagnetic anisotropy, comprising the steps of:

[0082] Step a, preparation of CoFe 2 o 4 Nanofibers;

[0083] Step b, preparation of core-shell structure CoFe 2 o 4 @BaTiO 3 Nanofibers;

[0084] Step c, preparation of CoFe 2 o 4 @BaTiO 3 -P(VDF-TrFE) based composite medium;

[0085] Step d, preparing a polymer-based composite medium with ferromagnetic anisotropy.

[0086] A method for preparing a polymer-based composite medium with ferromagnetic anisotropy described in this embodiment, in step a, CoFe 2 o 4 The preparation method of nanofiber comprises the steps:

[0087] Step a1, weighing cobalt hexahydrate, ferric nitrate nonahydrate, and citric acid of a certain quality respectively according to the ratio of the amount of substances, and set aside;

[0088] Step a2, adding cobalt pinate hexahydrate and ferric nitrate nonahydrate weighed in step a1 into the ethanol solution, stirring evenly...

specific Embodiment approach 3

[0110] A method for preparing a polymer-based composite medium with ferromagnetic anisotropy, comprising the steps of:

[0111] Step a, preparation of CoFe 2 o 4 Nanofibers;

[0112] Step b, preparation of core-shell structure CoFe 2 o 4 @BaTiO 3 Nanofibers;

[0113] Step c, preparation of CoFe 2 o 4 @BaTiO 3 -P(VDF-TrFE) based composite medium;

[0114] Step d, preparing a polymer-based composite medium with ferromagnetic anisotropy.

[0115] CoFe in step a of the preparation method of a polymer-based composite medium with ferromagnetic anisotropy described in this embodiment 2 o 4 The preparation method of nanofiber comprises the steps:

[0116] Step a1, weighing cobalt hexahydrate, ferric nitrate nonahydrate, and citric acid of a certain quality respectively according to the ratio of the amount of substances, and set aside;

[0117] Step a2, adding cobalt pinate hexahydrate and ferric nitrate nonahydrate weighed in step a1 into the ethanol solution, stirring ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com