Adhesive repair-promoting hemostatic sponge and preparation method thereof

A technology of hemostatic sponge and hydroxysuccinimide ester, which is applied in the field of biomedical materials, can solve the problems of weak tissue adhesion, low mechanical strength of sponge, weak cross-linked network structure, etc., and achieve the effect of ensuring swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

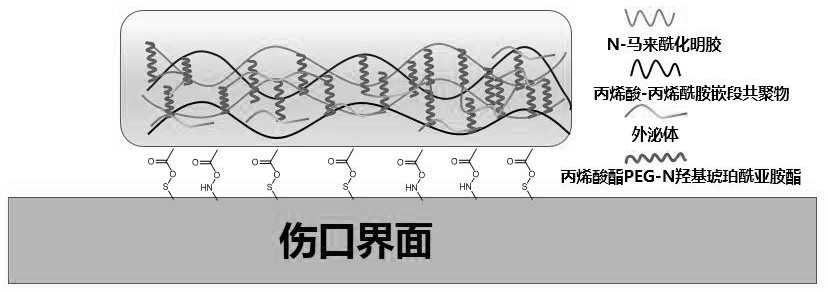

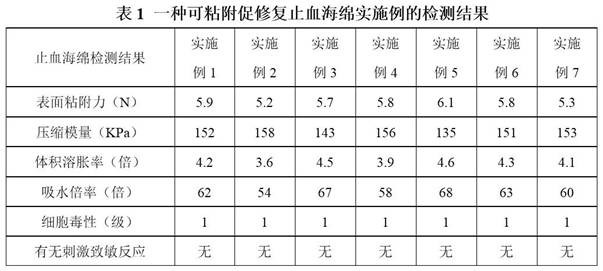

[0050] Example 1 The mass fraction of 20% N-maleoylated gelatin (60-90KDa, degree of substitution 85-95%), 0.75% exosomes, 3% acrylate PEG-N hydroxysuccinimide Add ester (3.4KDa) and 0.015% N, N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, and continue stirring for 20min. Add 1.0% maleic anhydride, 20% acrylic acid and 0.65% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone at 100-200rpm Stir at 100-200rpm until completely dissolved, then add sodium hydroxide solution to neutralize until the neutralization degree is 50% under stirring at 100-200rpm, pre-polymerize for 30min under a UV lamp at a power of 150W, a wavelength of 365nm, and atomize and spray 0.75% acrylic acid A mixture of N-hydroxysuccinimide ester and 0.010% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, at a power of 150W, The wavelength is 365nm. After 15 minutes of polymerization under ultraviolet light, pre-freeze at -50°C for 4 hours. ...

Embodiment 2

[0051] Example 2 The mass fraction is 15% N-maleoylated gelatin (50-80KDa, substitution degree 85-95%), 0.5% exosomes, 2% acrylate PEG-N hydroxysuccinimide Add ester (2KDa) and 0.02% N, N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, and continue stirring for 20min. Add 1.25% maleic anhydride, 25% acrylic acid and 0.8% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone at 100-200rpm Stir at 100-200rpm until completely dissolved, add sodium hydroxide solution and disodium hydrogen phosphate solution to neutralize to 60% under stirring at 100-200rpm, pre-polymerize under UV lamp for 40min with a power of 150W, a wavelength of 365nm, fog Spray the mixture of 0.5% N-hydroxysuccinimide acrylate and 0.007% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone , at a power of 150W, a wavelength of 365nm, after 10 minutes of polymerization under a UV lamp, pre-freeze at -50°C for 4 hours, and then vacuumize after the end, a...

Embodiment 3

[0052] Example 3 N-maleoylated gelatin (70-100KDa, substitution degree 85-95%) with a mass fraction of 25%, 1.0% exosomes, 4% acrylate PEG-N hydroxysuccinimide Add ester (5KDa) and 0.01% N, N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, and continue stirring for 20min. Add 0.75% maleic anhydride, 15% acrylic acid and 0.5% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone at 100-200rpm Stir at 100-200rpm until completely dissolved, add sodium hydroxide solution and sodium bicarbonate solution to neutralize to 40% under stirring at 100-200rpm, pre-polymerize under UV lamp for 20min under power of 150W, wavelength of 365nm, and atomize Spray a mixture of 1.0% N-hydroxysuccinimide acrylate and 0.013% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone, After polymerization at 150W, wavelength 365nm, under UV light for 20min, pre-freeze at -50°C for 4 hours, then vacuumize after completion, the vacuum degree should b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com