Preparation method of meta-aramid-based polyamide composite nanofiltration membrane

A composite nanofiltration membrane and polyamide-based technology, which is applied in the field of nanofiltration membrane materials to achieve high physical and chemical stability, scale-up and industrial application, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

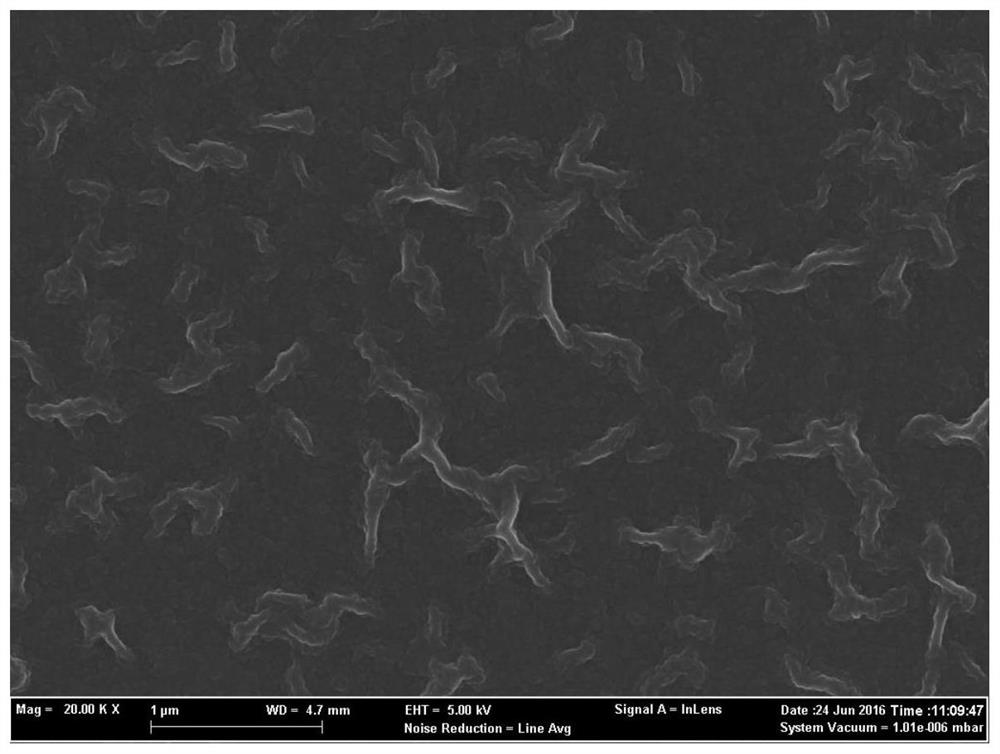

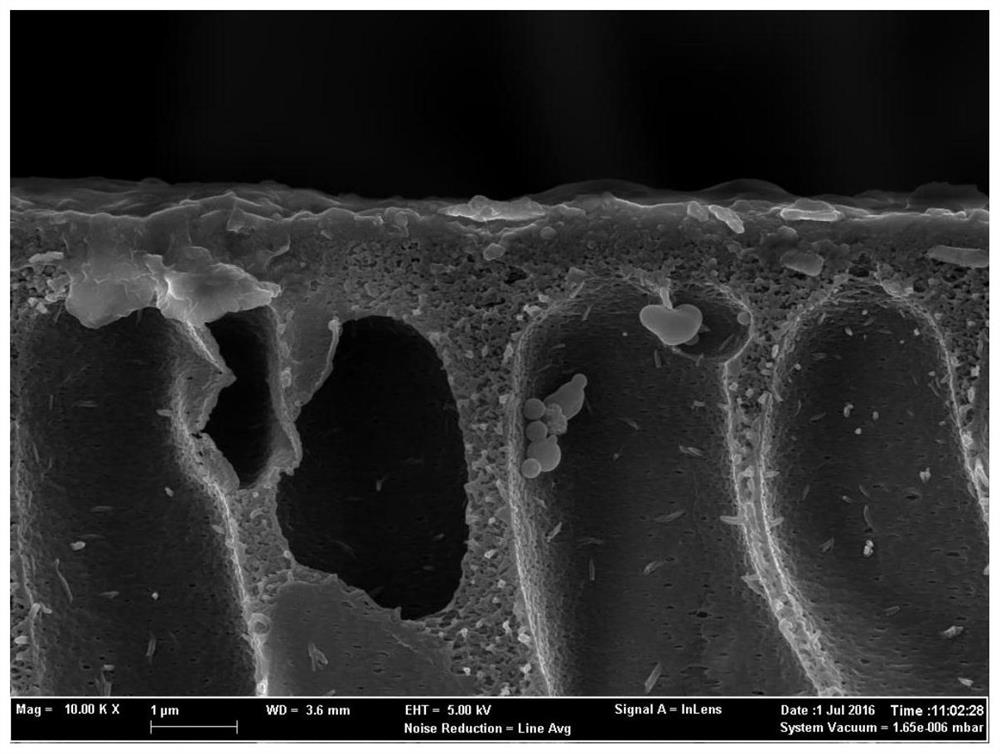

[0026] First, a homogeneous solution containing 12.5wt.% meta-aramid, 1.5wt.% polyvinylpyrrolidone, 4.5wt.% lithium chloride, 3.0wt.% acetone, and 77.5wt.% dimethylacetamide was used as a film-making solution , the meta-aramid porous base membrane was prepared by phase inversion method.

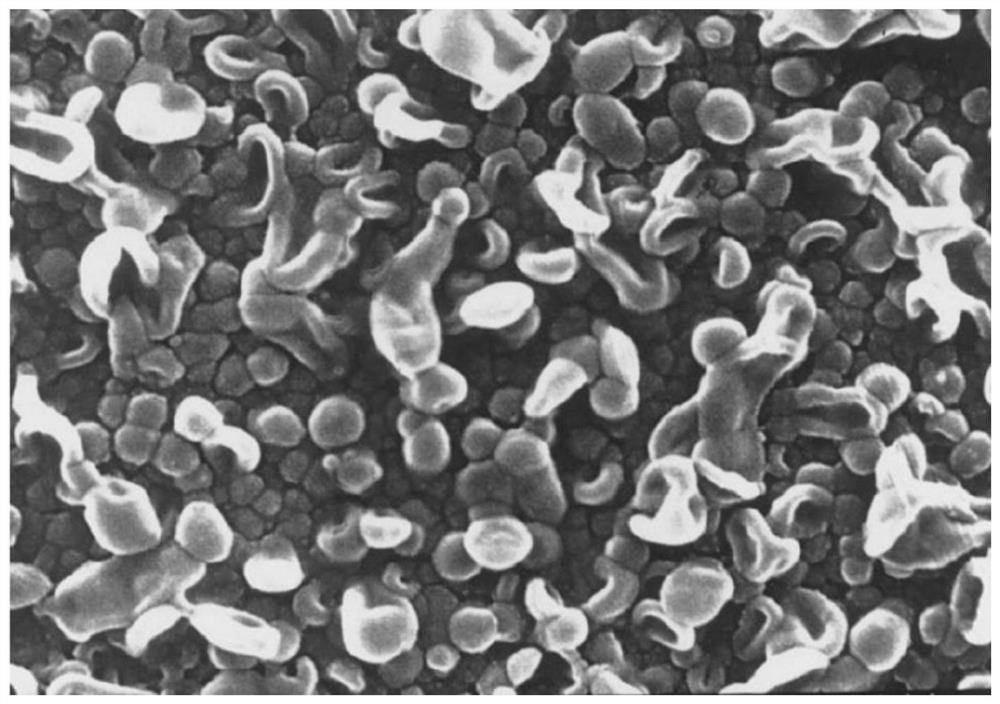

[0027] Secondly, after immersing the prepared meta-aramid porous base membrane in a piperazine aqueous solution with a concentration of 1.5wt.% for 2min, take out the piperazine solution remaining on the surface with a rubber roller, and then immerse it at a concentration of 0.2% (w / v) In the trimesoyl chloride n-hexane solution, react for 20s, take out the membrane and transfer it to an oven at 70°C for heat treatment for 5min, and finally immerse the membrane in deionized water for rinsing to obtain a meta-aramid-based polyamide composite nanofiltration membrane .

[0028] The pure water flux of the membrane was measured with deionized water, and the rejection rate of monovalent salt and ...

Embodiment 2

[0032] Using the meta-aramid membrane in Example 1 as the base membrane, immerse the prepared meta-aramid porous base membrane in a piperazine aqueous solution with a concentration of 1.5wt.% for 2 minutes, then remove the residue on the surface with a rubber roller. Piperazine solution, then immersed in trimesoyl chloride n-hexane solution with a concentration of 0.1% (w / v), reacted for 30s, took out the membrane and transferred it to an oven at 80°C for heat treatment for 4min, and finally immersed the membrane in deionized water for rinsing , to obtain the meta-aramid-based polyamide composite nanofiltration membrane.

[0033] The pure water flux of the membrane was measured with deionized water, and the rejection rate of monovalent salt and divalent salt was measured with 2000mg / L magnesium sulfate and 2000mg / L sodium chloride solution. The operating pressure was 0.6MPa and the temperature was 25°C.

[0034] The test results are as follows:

[0035]

Embodiment 3

[0037] First, a homogeneous solution containing 15wt.% meta-aramid, 4.0wt.% polyethylene glycol, 5wt.% lithium chloride, 2.0wt.% acetone, and 74wt.% dimethylacetamide was used as a film-making solution. The meta-aramid porous base membrane was prepared by phase inversion method.

[0038] Secondly, after immersing the prepared meta-aramid porous base membrane in a piperazine aqueous solution with a concentration of 1.5wt.% for 3 minutes, take out the piperazine solution remaining on the surface with a rubber roller, and then immerse it at a concentration of 0.15% (w / v) In the trimesoyl chloride n-hexane solution, react for 40s, take out the membrane and transfer it to an oven at 80°C for heat treatment for 5min, and finally immerse the membrane in deionized water for rinsing to obtain a meta-aramid-based polyamide composite nanofiltration membrane .

[0039] The pure water flux of the membrane was measured with deionized water, and the rejection rate of monovalent salt and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com