Catalyst for low-temperature catalytic degradation of straight-chain alkane and preparation method thereof

A technology for straight-chain alkanes and low-temperature catalysis, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as low catalytic activity, limit the application of noble metal catalysts, and expensive costs, and achieve the preparation process And the equipment is simple, good industrial application prospects, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

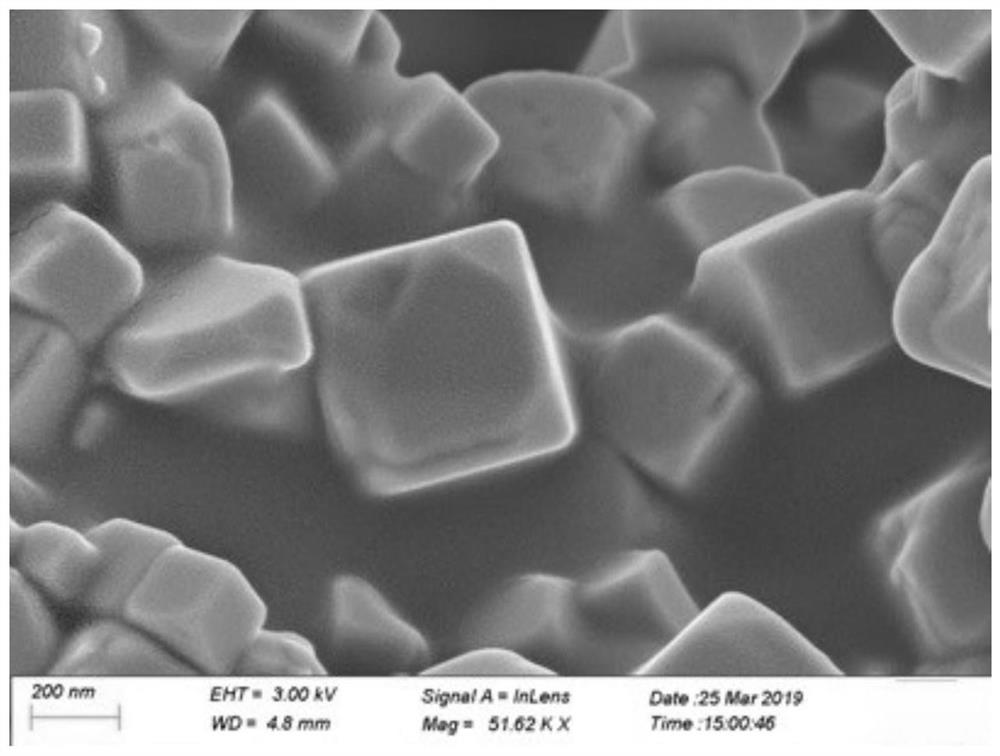

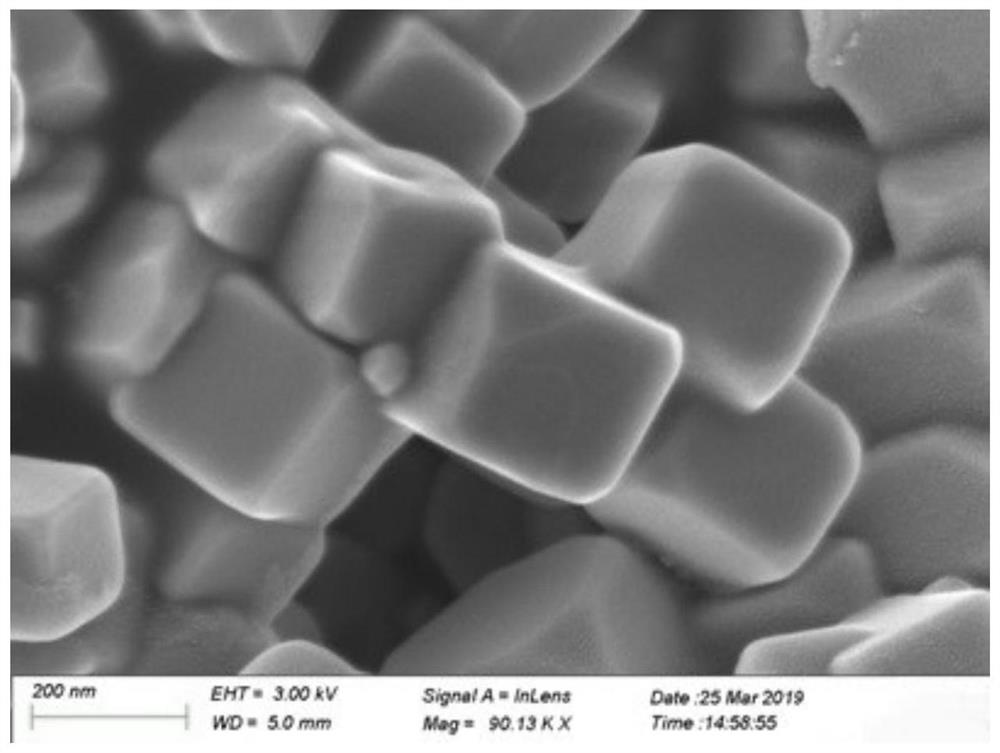

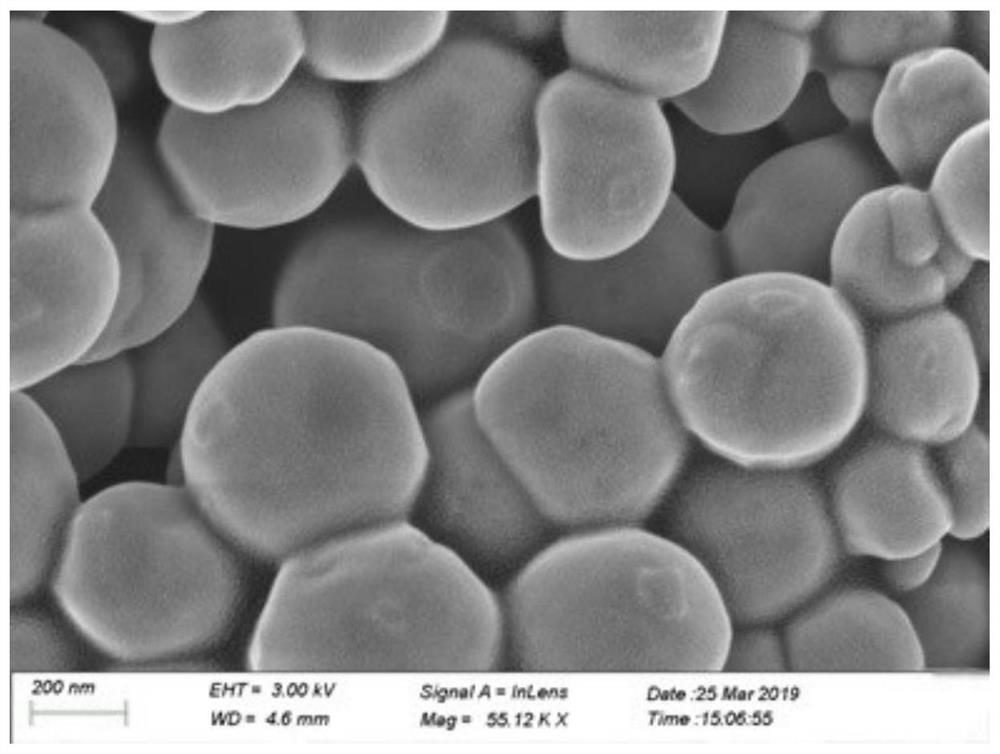

Image

Examples

Embodiment 1

[0031] The preparation of surface modified cobalt oxide catalyst comprises the following steps:

[0032] (1) Take 105mL ammonia water and add it to 800mL deionized water solution to get 1.5mol / L ammonia water solution;

[0033] (2) Take 0.75g potassium chloride and add it to 20mL deionized water solution to prepare 0.5mol / L potassium chloride solution;

[0034] (3) Add 116.4g of cobalt nitrate hexahydrate powder into 200mL of deionized water, and stir for 30 minutes to completely dissolve the powder to obtain a 2mol / L cobalt nitrate solution;

[0035] (4) Add 10mL of the prepared potassium chloride solution into the cobalt nitrate solution in step (3), and stir for 60 minutes to fully mix the solution to obtain a mixed solution;

[0036] (5) Add the prepared ammonia solution dropwise to the surface-modified cobalt nitrate solution in step (4), stir while adding dropwise and measure the pH value of the solution. When the pH is equal to 11, stop adding ammonia solution. Stirri...

Embodiment 2

[0041] The preparation of surface modified cobalt oxide catalyst comprises the following steps:

[0042] (1) Take 35mL ammonia water and add it to 800mL deionized water solution to prepare 0.5mol / L ammonia water solution;

[0043] (2) Take 1.5g potassium chloride and add it to 20mL deionized water solution to prepare a 1mol / L potassium chloride solution;

[0044] (3) Add 116.4g of cobalt nitrate hexahydrate powder into 200mL of deionized water, and stir for 30 minutes to completely dissolve the powder to obtain a 2mol / L cobalt nitrate solution;

[0045] (4) Add 10mL of the prepared potassium chloride solution into the cobalt nitrate solution in step (3), and stir for 60 minutes to fully mix the solution to obtain a mixed solution;

[0046] (5) Add the prepared ammonia solution dropwise to the surface-modified cobalt nitrate solution in step (4), stir while adding dropwise and measure the pH value of the solution. When the pH is equal to 11, stop adding ammonia solution. Stir...

Embodiment 3

[0051] The preparation of surface modified cobalt oxide catalyst comprises the following steps:

[0052] (1) Take 105mL ammonia water and add it to 800mL deionized water solution to get 1.5mol / L ammonia water solution;

[0053] (2) Take 0.15g of potassium chloride and add it to 20mL of deionized aqueous solution to prepare a 0.1mol / L potassium chloride solution;

[0054] (3) Add 58.2g of cobalt nitrate hexahydrate powder into 200mL of deionized water, and stir for 30 minutes to completely dissolve the powder to obtain a 1mol / L cobalt nitrate solution;

[0055] (4) Add 10mL of the prepared potassium chloride solution into the cobalt nitrate solution in step (3), and stir for 60 minutes to fully mix the solution to obtain a mixed solution;

[0056] (5) Add the prepared ammonia solution dropwise to the surface-modified cobalt nitrate solution in step (4), stir while adding dropwise and measure the pH value of the solution. When the pH is equal to 11, stop adding ammonia solution. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com