Aluminum alloy electric arc additive manufacturing quality control system and method

A quality control method and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of reducing porosity, stacking current, voltage fluctuation, increasing wire manufacturing costs, etc., and achieve the goal of eliminating pores, good plasticity, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

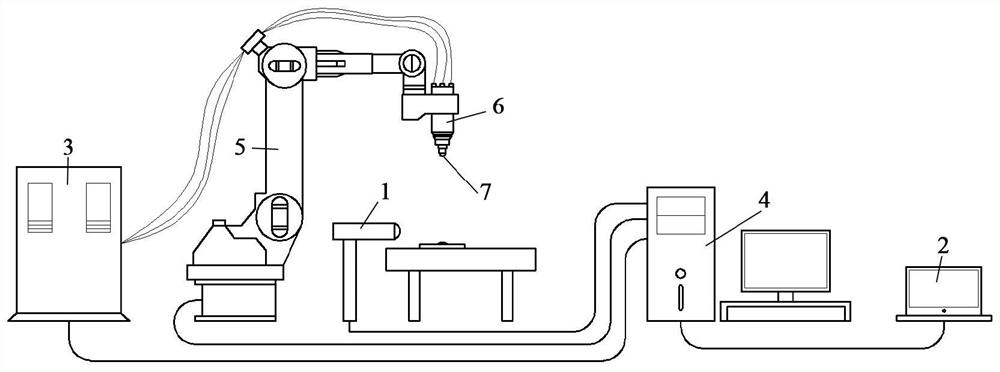

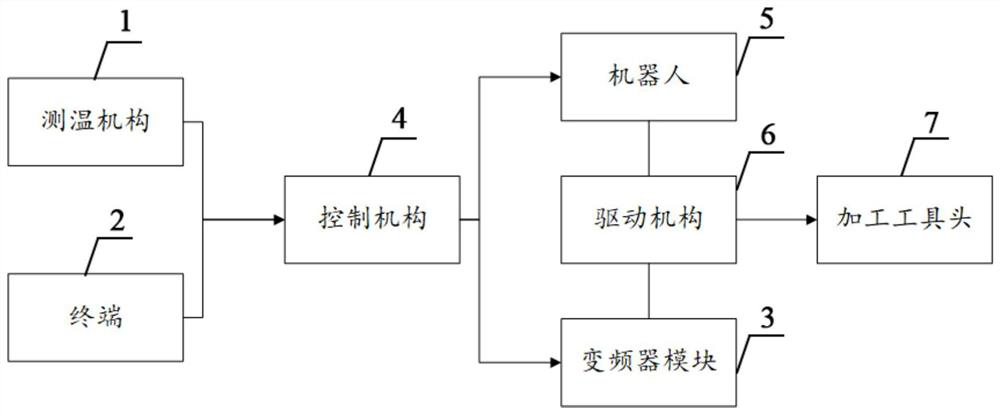

Embodiment 1

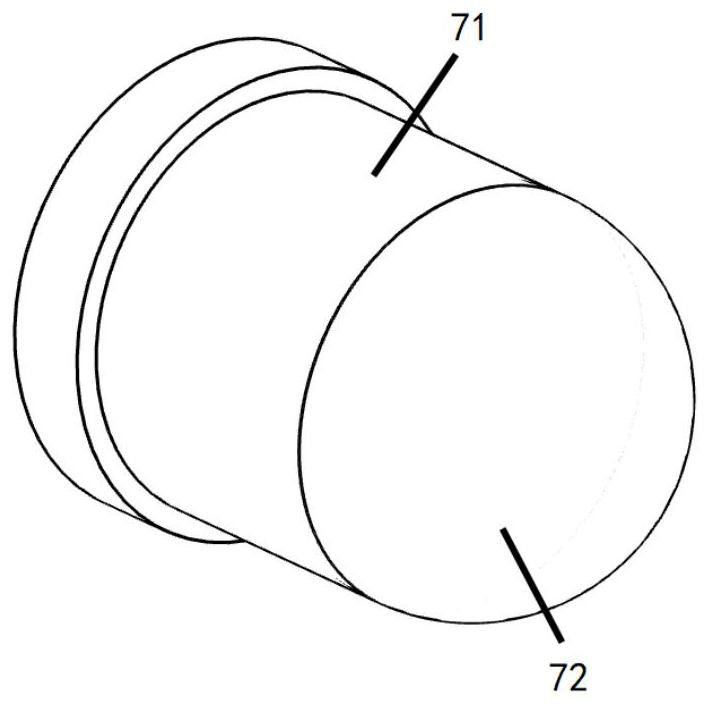

[0065] In this embodiment, the quality control system is used to control the quality of the aluminum alloy arc additive manufacturing, and each parameter is determined before execution: the arc additive manufacturing process used in this embodiment is tungsten inert gas welding (TIG, Tungsten Inert Gas). , the stacking current is 200A, the stacking travel speed is 300mm / min, the wire feeding speed is 2000mm / min, the wire used is ER2319 aluminum wire, the base metal used is 2219 aluminum, and the width of the single stacking metal is 7.6mm; determine the material of the processing tool head , and the size parameters of the processing tool head are determined according to the width of the single-channel deposited metal in the aluminum alloy arc additive manufacturing. In this embodiment, the material of the processing tool head is H13 steel, and its end diameter D is 90% of the width of the single-channel deposited metal. The overall length L of the processing tool head is 6 cm. ...

Embodiment 2

[0075] In this embodiment, the quality control system is used to control the quality of the aluminum alloy arc additive manufacturing, and each parameter is determined before execution: the arc additive manufacturing process used in this gas welding), the stacking current is 230A, the stacking travel speed is 300mm / min, the wire feeding speed is 1800mm / min, the wire material used is ER5183 aluminum wire, the base metal used is 6061 aluminum, and the width of the single stacking metal is 8.2mm; determine the processing tool The size parameters of the machining tool head are determined according to the width of the single-track deposited metal in the aluminum alloy arc additive manufacturing. In this embodiment, the material of the machining tool head is H11 steel, and the end diameter D is taken as the width of the single-track stacked metal. 85% is 7mm, the overall length L of the processing tool head is 8cm, and the following parameters are preset in the control mechanism: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com