EVA foam material and preparation method thereof

A technology of foaming materials and raw materials, which is applied in the field of EVA foaming materials and its preparation, can solve the problems of irritation, poor wear resistance, and not easy to degrade, etc., and achieve excellent wear resistance, rebound performance and stretching Increased strength and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

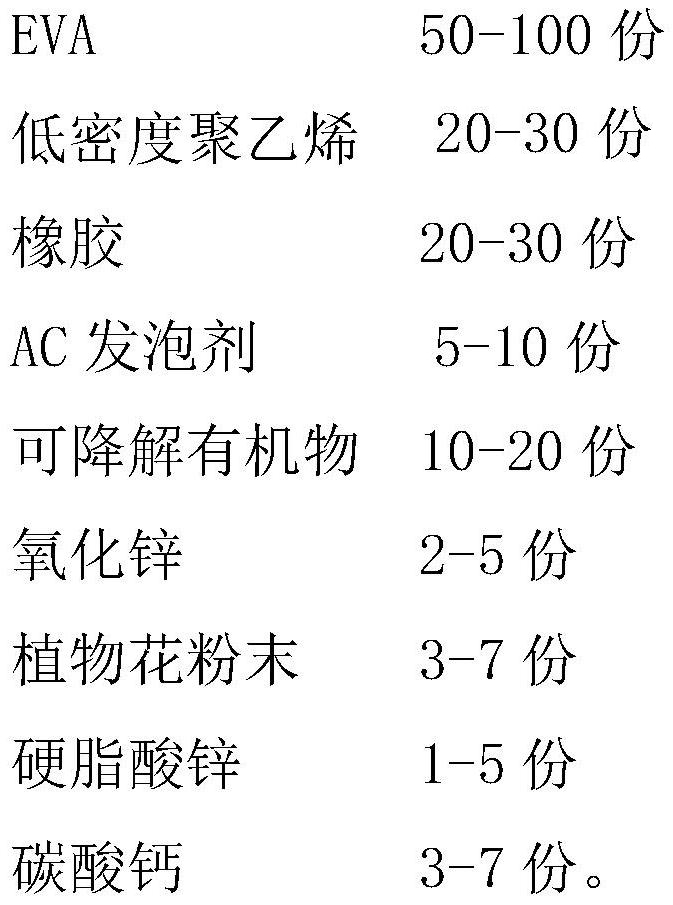

Examples

Embodiment 1

[0024]

[0025] Preparation method: S1. After mixing EVA, low-density polyethylene, rubber, degradable organic matter, plant flower powder and calcium carbonate evenly, extrude through a twin-screw extruder, the extrusion temperature is 150-220 degrees Celsius, and the extrusion time is for 3-5min, and then granulated to obtain granule A;

[0026] S2. After mixing the granular matter A, AC foaming agent, zinc oxide and zinc stearate evenly, enter the internal mixer for mixing. Nitrogen is used as the protective gas inside the internal mixer, and the mixing temperature is 120-140 degrees Celsius. The hydrogen flow rate is 1.9-2.8m 3 / h, the interior of the internal mixer is in a slight negative pressure state, and then granulated to obtain granules B;

[0027] S3. The finished product is obtained after the particles B are injected by the EVA injection machine, vulcanized, and foamed outside the mold.

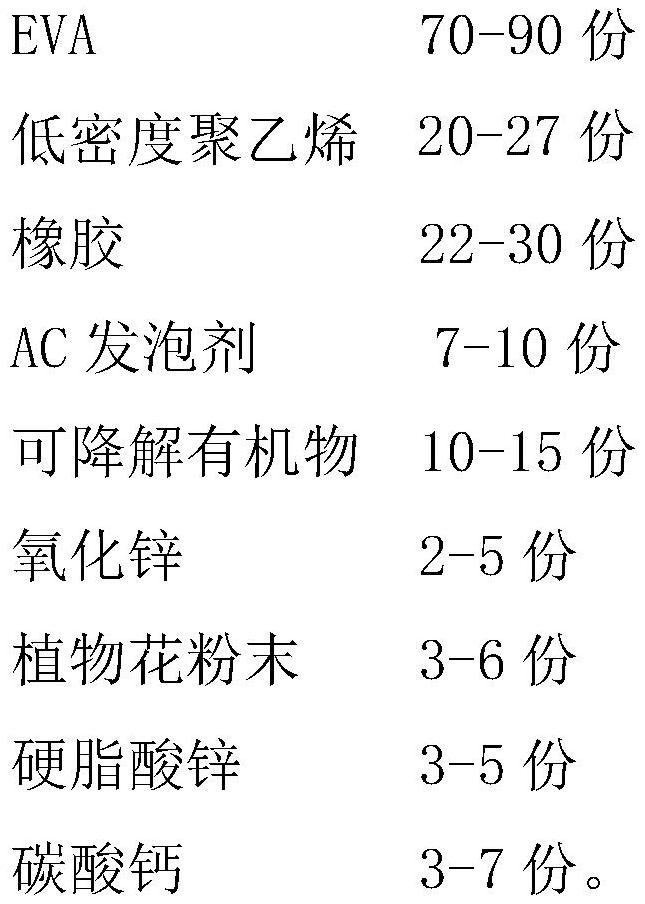

Embodiment 2

[0029]

[0030] Preparation method: with embodiment 1.

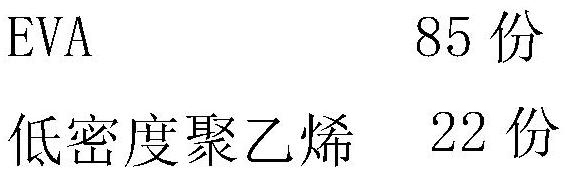

[0031]

[0032] Preparation method: with embodiment 1.

[0033]

[0034]

[0035] Preparation method: with embodiment 1.

[0036]

[0037] Preparation method: with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap