Environment-friendly nodular cast iron antirust oil

A technology of nodular cast iron and anti-rust oil, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient heat and humidity resistance and salt spray resistance, general water replacement performance, and short anti-rust time, etc., and achieve penetration Strong ability and water replacement performance, which is conducive to ocean transportation and protection from corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

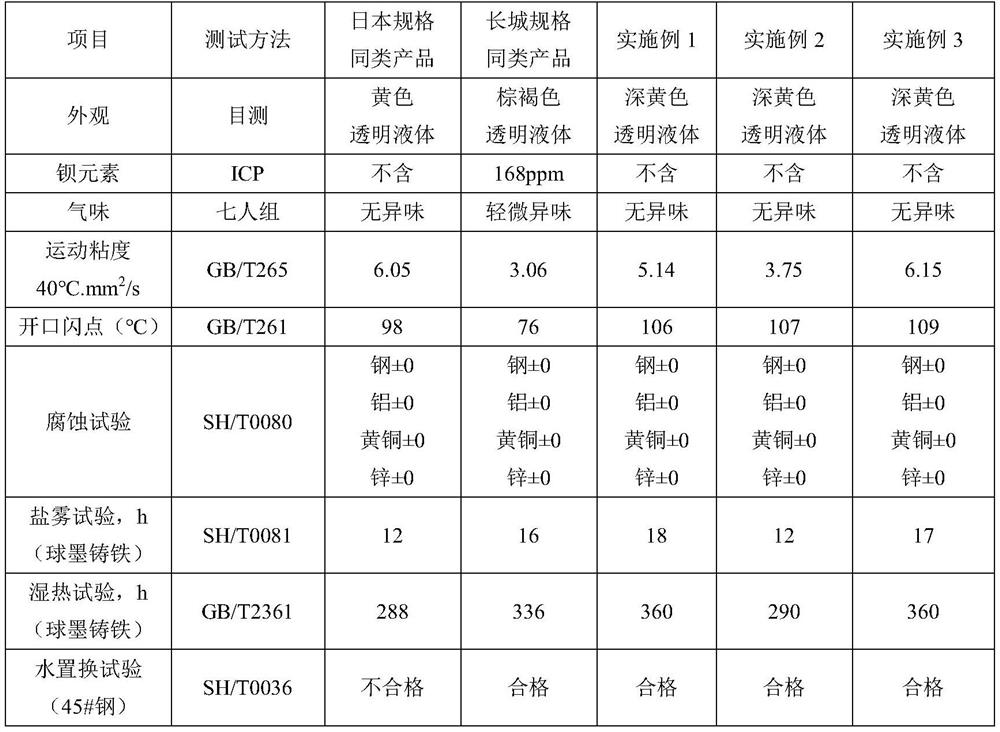

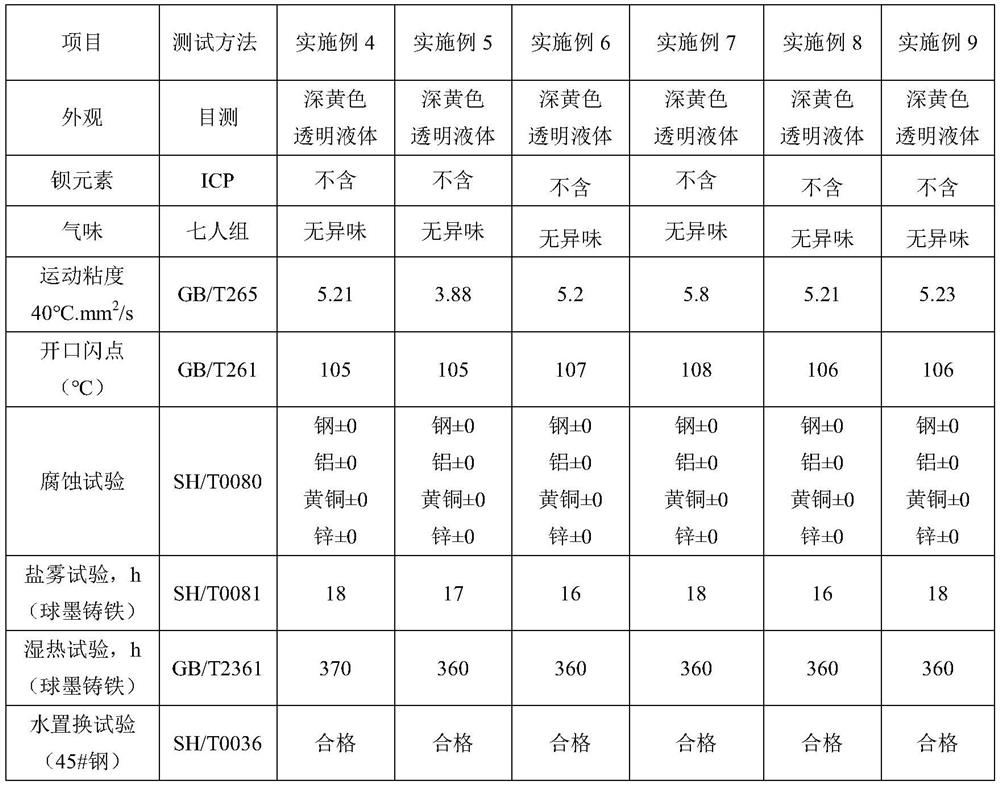

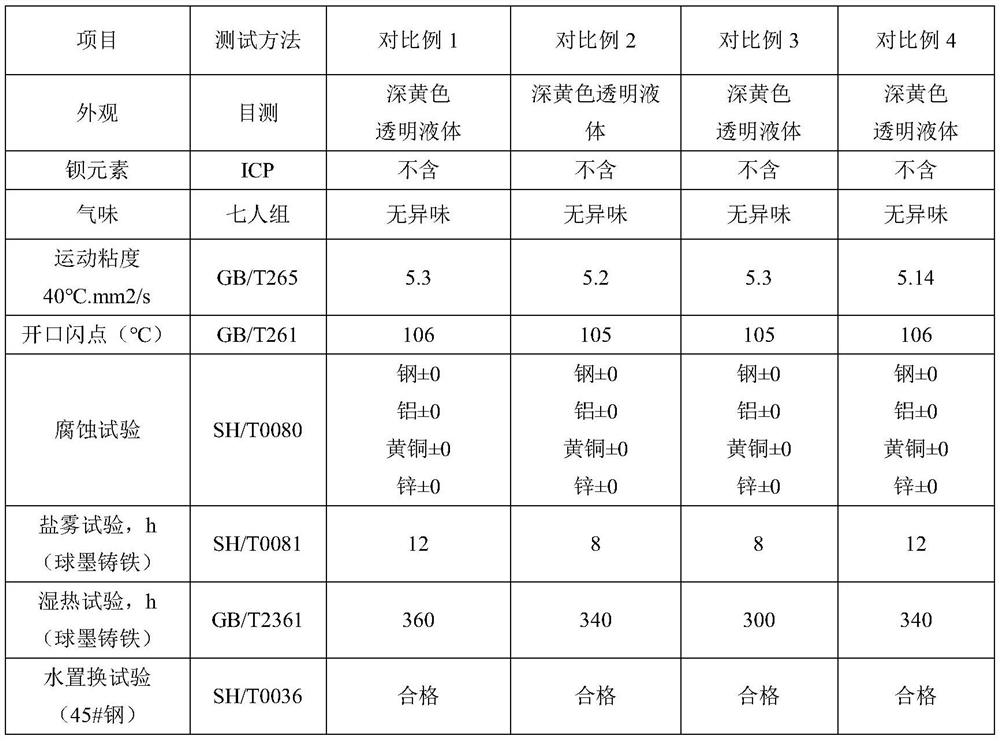

Examples

Embodiment 1

[0026] 1 part of benzotriazole, 0.5 part of magnesium lanolin soap, 0.5 part of sulfonated lanolin calcium soap, 9 parts of zinc naphthenate, 2 parts of octadecyl ammonium N-oleoyl sarcosine, 2 parts of dodecenyl butyl 1 part of diacid, 10 parts of neutral calcium dinonylnaphthalene sulfonate, 3 parts of sodium petroleum sulfonate, 3 parts of VCI granule, 1 part of hydroquinone, long-chain linear alkylbenzene high alkali value synthetic calcium sulfonate 5 parts, 3 parts of borated polyisobutylene monosuccinimide, 50 parts of 60N naphthenic base oil, 50 parts of isoparaffin solvent oil.

[0027] The method for preparing above-mentioned environment-friendly nodular cast iron antirust oil comprises the steps:

[0028] (1) Add the film-forming agent involved in this scheme into the base oil, heat up to 120°C, and stir to dissolve;

[0029] (2) Cool down the mixture obtained in the above steps and maintain the temperature at 60-70°C, add the corrosion inhibitor, rust inhibitor, d...

Embodiment 2

[0033]0.2 parts of dodecyl benzotriazole, 2 parts of lanolin magnesium soap, 1 part of zinc naphthenate, 2 parts of octadecyl ammonium salt of N-oleoyl sarcosine, 1 part of dodecenyl succinic acid half ester 3 parts, 3 parts of neutral calcium dinonyl naphthalene sulfonate, 0.5 parts of polyisobutylene resin, 1.5 parts of tert-butyl phenolic resin, 3 parts of sodium petroleum sulfonate, 0.1 part of 2,6-di-tert-butyl-p-cresol, Long-chain linear alkylbenzene high base value synthetic calcium sulfonate 5 parts, polyisobutylene bis-succinimide 1.5 parts, 60N naphthenic base oil 34.5 parts, isoparaffin solvent oil 37.2 parts.

Embodiment 3

[0035] 0.3 parts of benzotriazole, 2 parts of sulfonated lanolin calcium soap, 1.5 parts of zinc naphthenate, 2 parts of octadecyl ammonium salt of N-oleoyl sarcosine, 1 part of hexadecenyl succinic acid, neutral 10 parts of calcium dinonylnaphthalene sulfonate, 3 parts of sodium petroleum sulfonate, 1.0 parts of VCI particles, 0.5 parts of tert-butylphenolic resin, 0.2 parts of 2,6-di-tert-butylhydroquinone, borated polyisobutylene mono 5 parts of succinimide, 33 parts of 70N naphthenic base oil, 40.2 parts of isoparaffin solvent oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com