Precursor solution of indium gallium zinc oxide thin film and preparation method of indium gallium zinc oxide thin film transistor

A technology of indium gallium zinc oxide and precursor liquid, which is applied in the direction of transistors, chemical instruments and methods, gallium/indium/thallium compounds, etc., can solve problems such as negative threshold voltage bias, improve negative threshold voltage bias, improve performance, The effect of reducing the concentration of oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

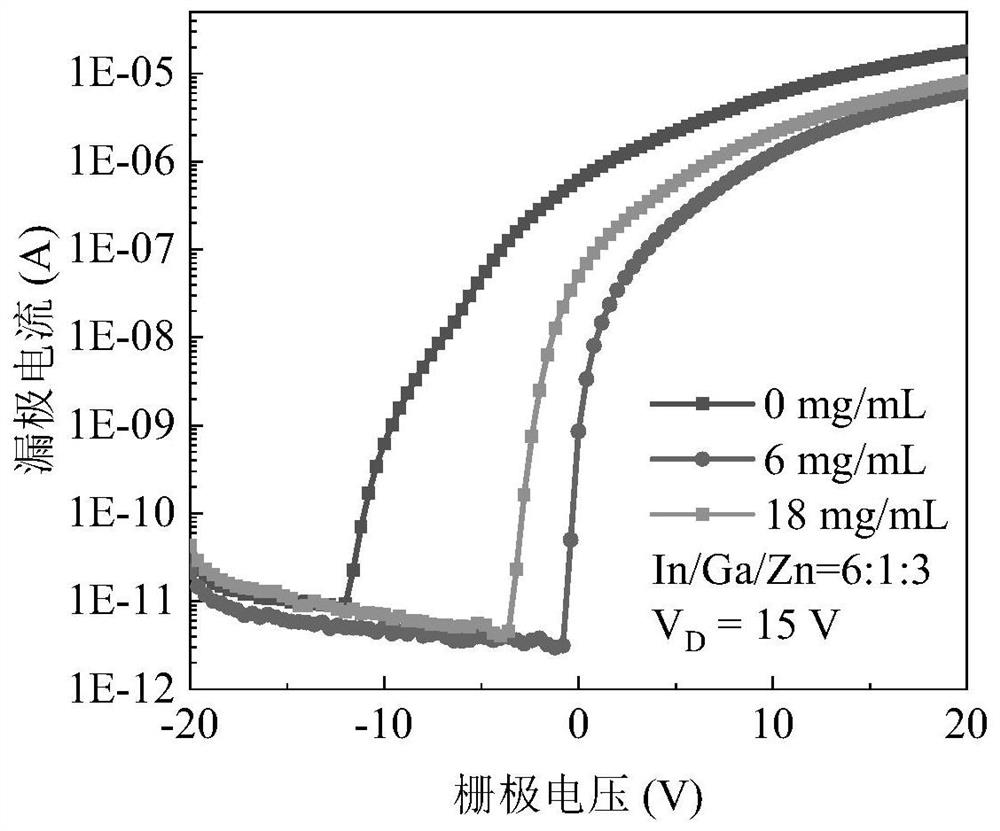

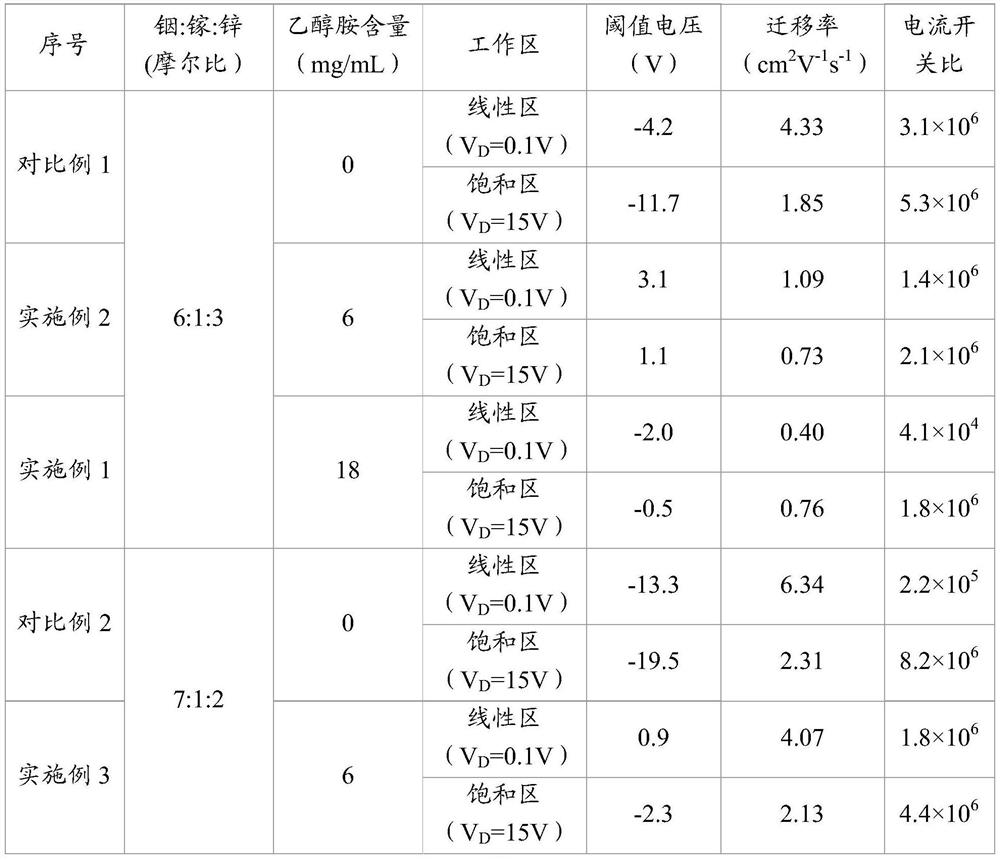

[0052] This embodiment provides a kind of precursor liquid of indium gallium zinc oxide thin film, and it comprises indium salt, gallium salt, zinc salt, stabilizer and solvent; Wherein indium salt is hydrated indium nitrate (In(NO 3 ) 3 ·3H 2 O); gallium salt is hydrated gallium nitrate (Ga(NO 3 ) 3 ·3H 2 O); the zinc salt is zinc nitrate hydrate (Zn(NO 3 ) 2 2H 2 O); the stabilizer is ethanolamine; the mass concentration of ethanolamine in the precursor solution is 18 mg / ml; the mol ratio of the indium ion, gallium ion and zinc ion in the precursor solution is 6:1:3; the solvent is 2-methoxy base ethanol.

[0053] This embodiment also provides a method for preparing an indium gallium zinc oxide thin film transistor using the above precursor solution, which includes the following steps:

[0054] (1) Preparing the precursor solution of the above-mentioned indium gallium zinc oxide thin film.

[0055] The specific method is: hydrated indium nitrate (In(NO 3 ) 3 ·xH ...

Embodiment 2

[0063] The difference between this example and Example 1 is that the mass concentration of ethanolamine in the precursor solution is 6 mg / ml. Other operating steps and parameters are all the same as in Example 1.

Embodiment 3

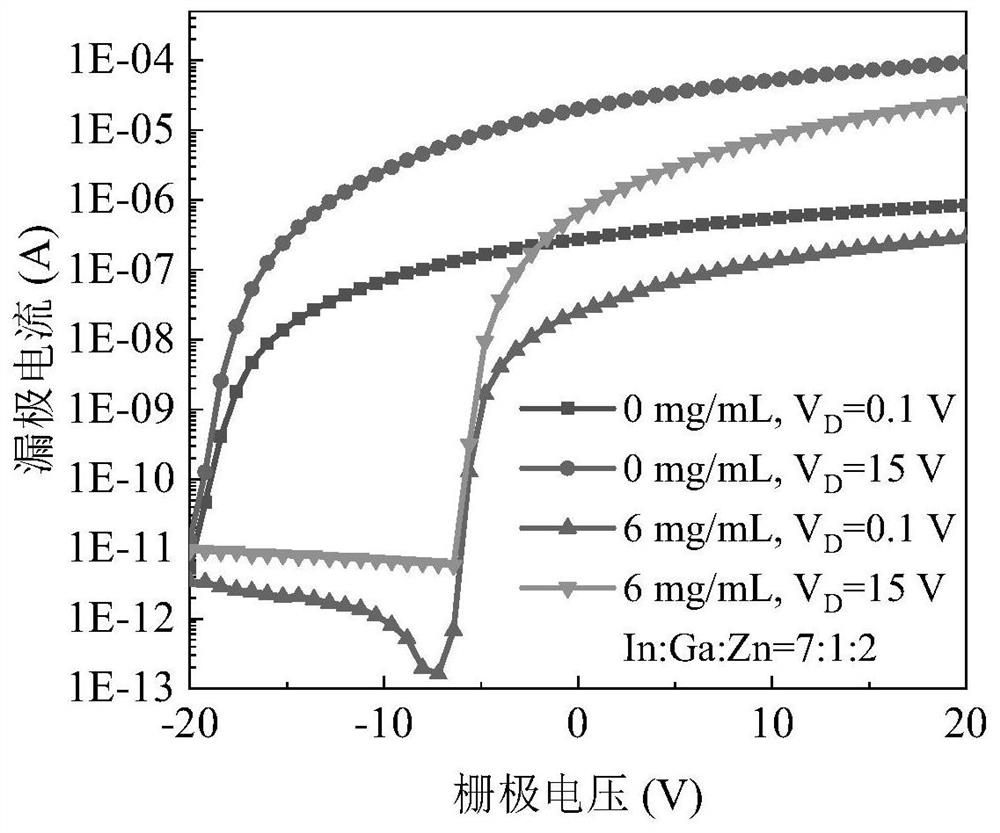

[0065] The difference between this embodiment and embodiment 2 is that the molar ratio of indium ions, gallium ions and zinc ions in the precursor solution is 7:1:2. Other operation steps and parameter are all identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com