Magnetic core-shell hydrogenation catalyst and method for preparing 2, 2, 4, 4-tetramethyl-1,3-cyclobutanediol

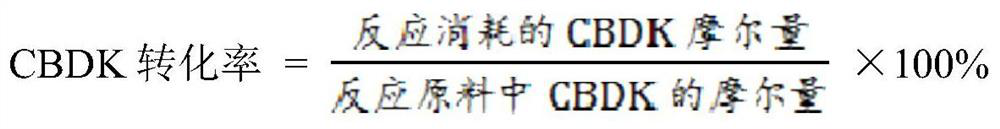

A hydrogenation catalyst, cyclobutanediol technology, applied in the direction of organic compound/hydride/coordination complex catalyst, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the loss of CBDO , complex operation, high economic cost and other problems, to achieve the effect of high conversion rate, high selectivity and fast hydrogenation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

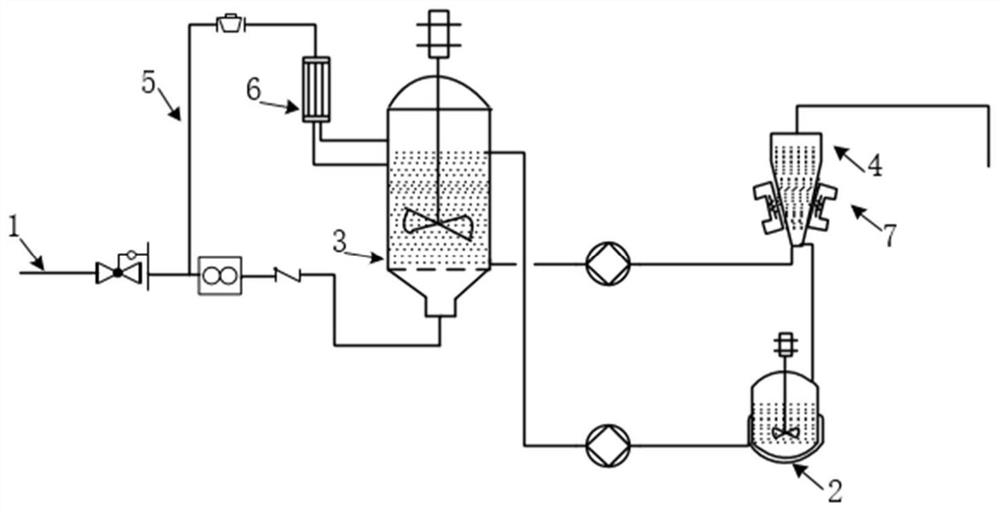

[0063] In a second aspect, the present invention provides a method for preparing the above-mentioned catalyst, the steps comprising:

[0064] a) Fe 3 o 4 Preparation of nanoparticles

[0065] Under the protection of nitrogen, dissolve the iron-containing precursor compound in ethylene glycol to obtain a transparent iron-containing solution; add sodium acetate, polyethylene glycol and sodium citrate, heat to 100-200°C, and stir for 1-3 hours; Crystallize the uniformly mixed solution at 100-200°C for 8-16 hours; wash the crystallized black solution with ethanol, and dry it in vacuum at 60-80°C for 10-20 hours to obtain Fe 3 o 4 Nanoparticles;

[0066] b) Fe 3 o 4 Preparation of @S

[0067] Will Fe 3 o 4 Nanoparticles are placed in dilute hydrochloric acid solution and ultrasonicated for 10-60 minutes to carry out surface acid treatment and magnetic separation of Fe 3 o 4 nanoparticles and washed with ethanol; the Fe 3 o 4 Nanoparticles are redispersed in the mixed s...

preparation example 1

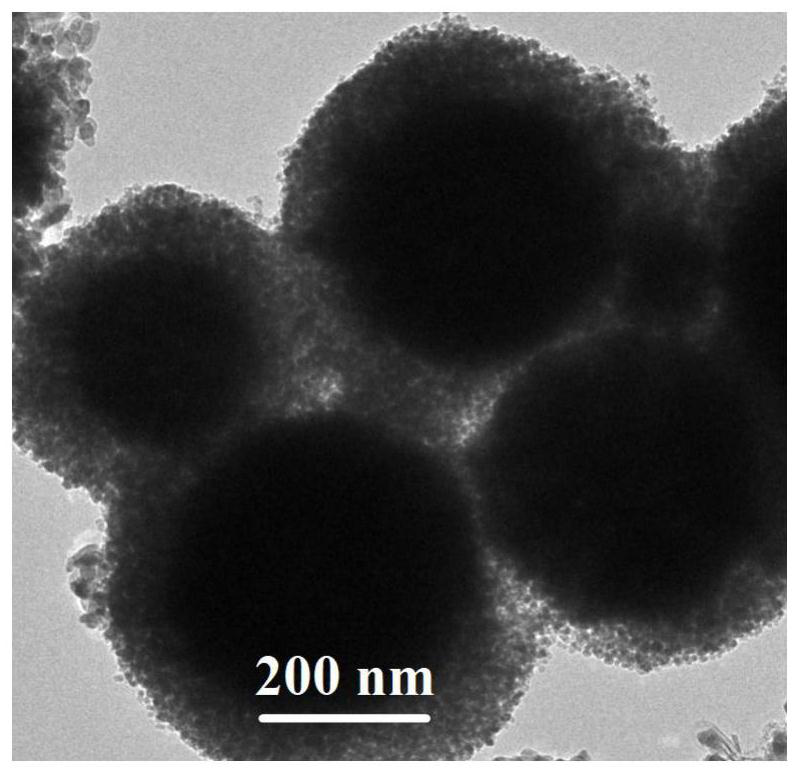

[0104] First, weigh 2.70 g of FeCl in sequence with an electronic balance 3 ·6H 2 O, 7.67g of sodium acetate, 2.10g of polyethylene glycol and 0.80g of sodium citrate were dissolved in 150mL of ethylene glycol and mixed uniformly; the above mixed solution was heated to 170°C and mechanically stirred for 1 hour to obtain a uniform black color solution; put the above solution into a polytetrafluoroethylene liner with a volume of 200mL, put it into a crystallization kettle and seal it, move it to a blast oven, and crystallize at 200°C for 16 hours; wait for the crystallization kettle to cool to room temperature , the magnet separates Fe 3 o 4 Nanoparticles, washed several times with ethanol, moved to a vacuum drying oven, and dried at 60°C for 12 hours;

[0105] Secondly, the above obtained Fe 3 o 4 Nanoparticles (0.5g) were dispersed in dilute hydrochloric acid (0.1mol / L) solution and ultrasonicated for 30min, washed with ethanol for 3 times and magnetically separated, redi...

preparation example 2

[0109] First, weigh 2.70 g of FeCl in sequence with an electronic balance 3 ·6H 2 O, 7.67g of sodium acetate, 2.10g of polyethylene glycol and 0.80g of sodium citrate were dissolved in 150mL of ethylene glycol and mixed uniformly; the above mixed solution was heated to 170°C and mechanically stirred for 1 hour to obtain a uniform black color solution; put the above solution into a polytetrafluoroethylene liner with a volume of 200mL, put it into a crystallization kettle and seal it, move it to a blast oven, and crystallize at 200°C for 16 hours; wait for the crystallization kettle to cool to room temperature , the magnet separates Fe 3 o 4 Nanoparticles were washed several times with ethanol, moved to a vacuum oven, and dried at 60°C for 12 hours; secondly, the Fe obtained above 3 o 4Nanoparticles (0.5g), dispersed in dilute hydrochloric acid (0.1mol / L) solution and sonicated for 30min, washed with ethanol for 3 times and magnetically separated, redispersed into a mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com