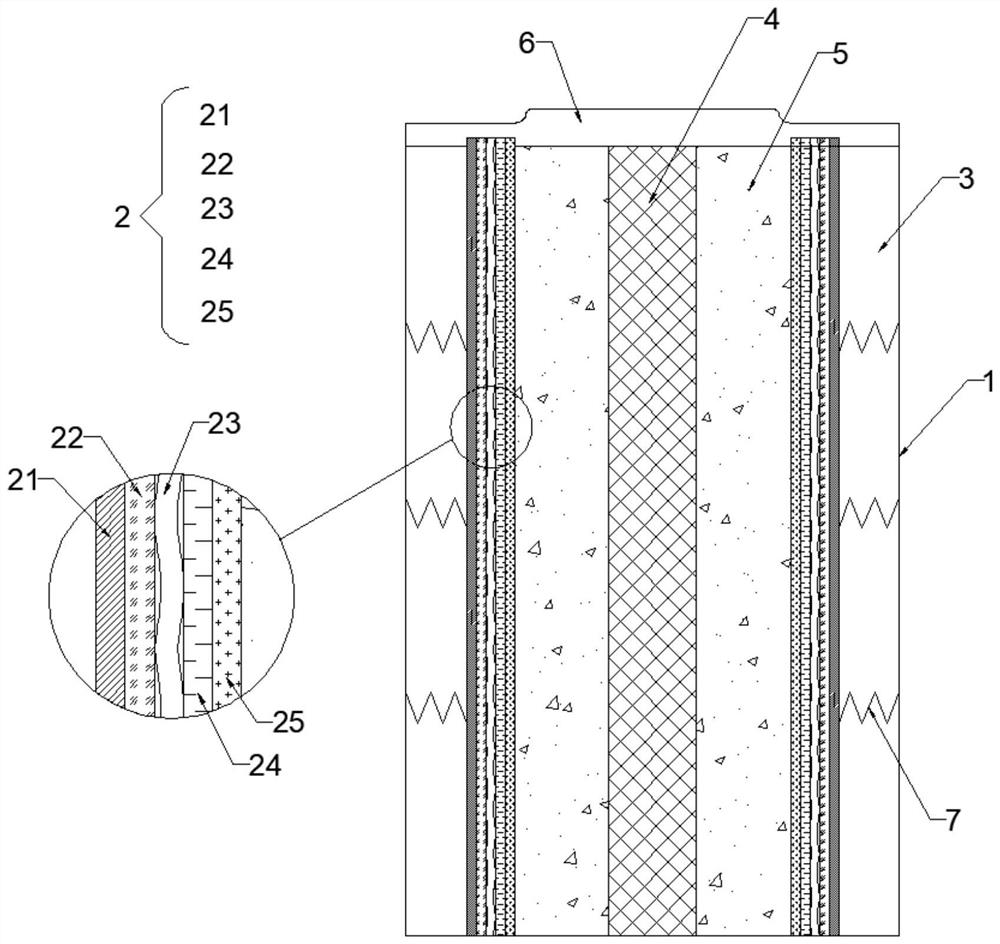

Porous zinc electrode, preparation method thereof and zinc-air battery comprising porous zinc electrode

A zinc electrode and porous structure technology, applied in electrode manufacturing, primary battery electrodes, battery electrodes, etc., can solve problems such as affecting output current, low electron speed of zinc flakes, electrolyte leakage, etc. Conducive to circulation and diffusion, and the effect of increasing the amount of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] In a specific embodiment, the present invention provides a kind of preparation method of porous zinc electrode, and described preparation method comprises:

[0101] (1) Prepare electroplating solution: add water and stir ruthenium source, zinc source, electrolyte and additive, obtain electroplating solution after completely dissolving;

[0102] (2) Use a template with a three-dimensional network structure as the cathode, and zinc as the anode, insert it into the electroplating solution containing the ruthenium source and soak for 5-10 minutes, and then apply a current between the anode and the cathode, using constant current method, constant voltage method or pulse method for electroplating;

[0103] (3) Post-treatment: the template deposited with the zinc layer is rinsed and dried in sequence to obtain a porous zinc electrode.

[0104] The porous zinc electrode prepared by the above preparation method has a three-dimensional network structure, a porosity of 70-80%, an...

Embodiment 1

[0110] This embodiment provides a preparation method of a porous zinc electrode, the preparation method comprising:

[0111] (1) Preparation of electroplating solution: add water and stir ruthenium source, zinc source, electrolyte and additives, and obtain electroplating solution after completely dissolving. Wherein, the ruthenium source is ruthenium chloride, and the concentration of ruthenium chloride is 4.8mg / L. The zinc source is zinc oxide, and the concentration of zinc oxide is 50g / L. The electrolyte is ferrous sulfate, sodium sulfate, sodium chloride, potassium chloride and copper chloride, the concentration of ferrous sulfate is 20g / L, the concentration of sodium sulfate is 35g / L, and the concentration of sodium chloride is 25g / L. The concentration of potassium chloride is 20g / L, and the concentration of copper chloride is 15g / L. The pH of the plating solution was 2.

[0112] (2) With porous iron having a three-dimensional network structure as the cathode and zinc a...

Embodiment 2

[0120] This embodiment provides a preparation method of a porous zinc electrode, the preparation method comprising:

[0121] (1) Preparation of electroplating solution: add water and stir ruthenium source, zinc source, electrolyte and additives, and obtain electroplating solution after completely dissolving. Wherein, the ruthenium source is ruthenium sulfate, and the concentration of ruthenium sulfate is 4.8 mg / L. The zinc source includes zinc oxide and zinc sulfate, the concentration of zinc oxide is 25g / L, and the concentration of zinc sulfate is 30g / L.

[0122] The electrolyte is ferrous chloride, sodium chloride, potassium sulfate, copper sulfate and copper chloride, the concentration of ferrous chloride is 30g / L, the concentration of sodium chloride is 30g / L, and the concentration of potassium sulfate is 18g / L , the concentration of copper sulfate is 16g / L, and the concentration of copper chloride is 5g / L. The pH of the electroplating solution is 3;

[0123] (2) With p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com