Preparation method of metal-acid-base function integrated catalyst and application of metal-acid-base function integrated catalyst in catalytic cracking of lignin ether bonds to prepare aromatic substances

A catalyst quality and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, organic compound preparation, etc., can solve problems such as difficult recovery, achieve separation and recovery difficulties, and avoid a large amount of The effect of low energy consumption for acid/alkali, reaction and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of PD / MGO-C and Its Catalytic Performance Experiment

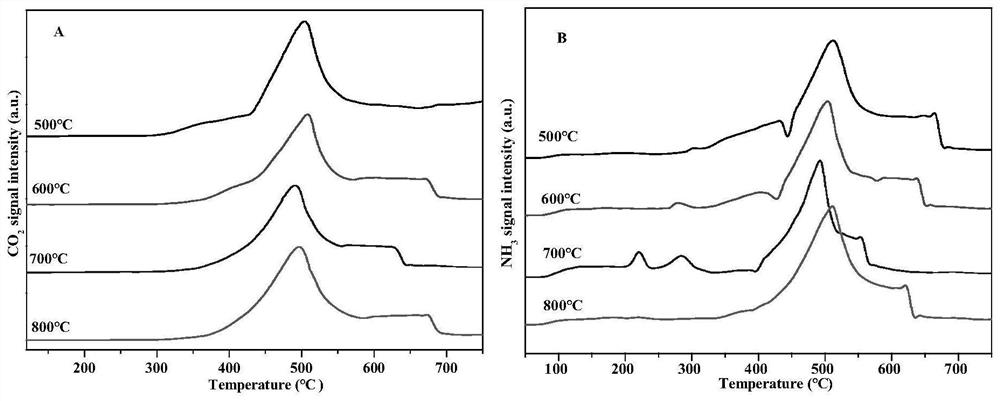

[0027] (1) Weigh 0.36 g of nine hydrogen nitrate and 0.17 g of citric acid into the crucible, add 3 ml of deionized water, and then add 1.0 g of nano magnesium oxide after stirring, and continue to stir in liquid volatiles at 80 ° C, The sample was then placed in a muffle furnace, and then warmed to 450 ° C for 2 h. After the calcination, the sample was transferred to the reduced tube, and 2 h was reduced by hydrogen at 500 ° C. Subsequently, the reducing furnace was heated to 700 ° C, and hydrogen was switched into nitrogen and purged for 60 min, and the furnace temperature was continued to adjust the heat treatment temperature of 1000 ° C. Nitrogen in 50 ~ 80 ml / min is mixed with methanol vapor by methanol steam generator (65 ° C water bath), and mixed gas enters the reduction furnace to modify MGO, and the mixed air access time is 10 min. Stopping the heating procedure after the mixture is ...

Embodiment 2

[0030] Example 2: Preparation of RU / MGO-C and its catalytic performance experiment

[0031] (1) in the same manner (1) in the first embodiment.

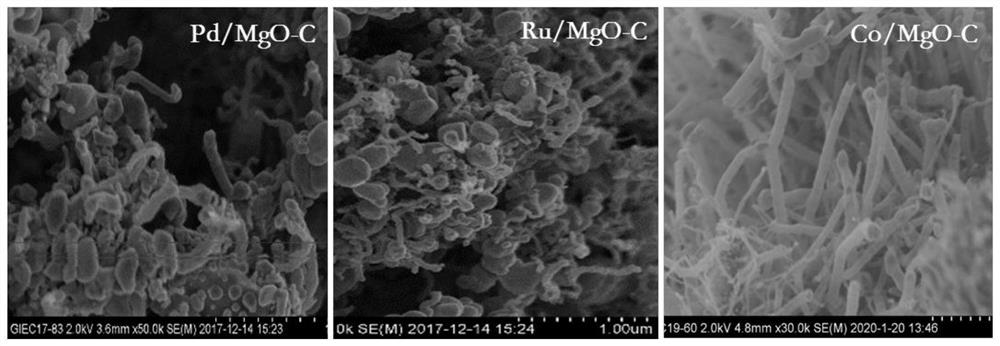

[0032] (2) Weigh 0.136 g of Rucl3, dissolved in 2.5 ml of anhydrous ethanol, continuously stirred and added 0.5 g of MgO-C sample, and uniformly dispersed the solid, stirred to ethanol all volatilize 2 h. After drying sample was ground, 2 h was reduced at 300 ° C (10 min) to obtain a Ru / MgO-C catalyst, and its SEM map see figure 1 .

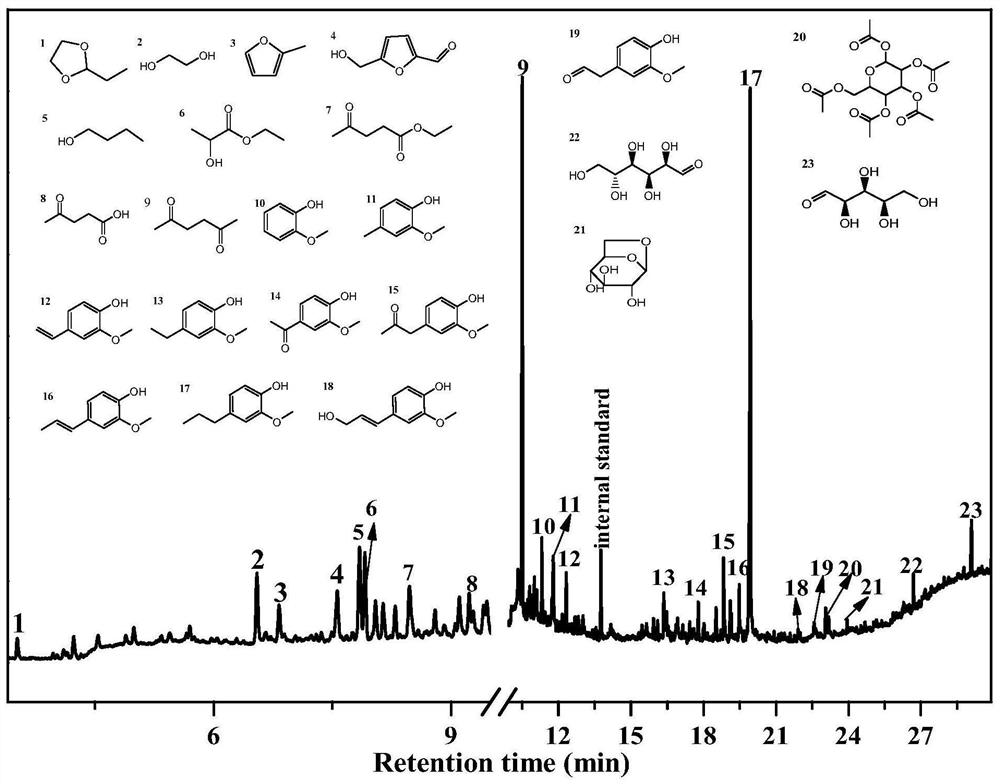

[0033] (3) Take 0.1 mmol dimer-creator chipphenol-glycerol-β-创 木 醚, 25 ml of ethyl acetate / water two-phase solvent (ethyl acetate / water = 4: 1, v / v) and 50 mGRU / mgO-C catalyst was added to 50 mL of Hakobloy reactor, and the gas was sealed with hydrogen. The gas was used for 3 times, and 15bar hydrogen was charged, the reaction temperature was 140 ° C, the reaction was 4 h, and the stirring speed was 500 rpm. The results of the reaction are shown in Table 1.

Embodiment 3

[0034] Example 3: Preparation of CO / MGO-C and Its Catalytic Performance Experiment

[0035] (1) in the same manner (1) in the first embodiment.

[0036] (2) Weigh 0.331G COCL 2 , Dissolved in 2.5 ml of anhydrous ethanol, continuously stirred and added 0.5 g of MgO-C sample, and uniformly dispersed the solid, stirred until all volatilizers were volatilized after each volatilization of 100 ° C for 2 h. After drying samples were ground, 2 h was reduced in a 600 ° C reduction furnace (warmed by 30 min) to give a CO / MgO-C catalyst. SEM map figure 1 .

[0037] (3) Take 0.1 mmol dimer-creator chipphenol-glycerol-β-创 木 醚, 25 ml of ethyl acetate / water two-phase solvent (ethyl acetate / water = 4: 1, v / v) and 50 mg CO / MgO-C catalyst was added to 50 mL of the Hanse alloy reaction kettle, and the gas was sealed with hydrogen gas 3 times, and 15bar hydrogen was charged, the reaction temperature was 140 ° C, the reaction was 4 h, and the stirring velocity was 500 rpm. The results of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com