Carbon microsphere catalyst as well as preparation method and application

A technology of catalysts and carbon microspheres, which is applied in the field of carbon microsphere catalysts and preparations, can solve the problems of difficult coordination between catalyst activity and microwave absorption capacity, poor catalytic conversion effect, etc., and achieve good hydrothermal stability, high possibility, The effect of promoting chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Prepare 100ml of 6mol / L sulfuric acid solution, add 20g of glucose solid to it, stir until dissolved, then transfer the solution to a round bottom flask, heat up the oil bath to 120°C at 200r / min, and reflux for 10h. After cooling, the suction filtered solid was repeatedly washed with deionized water and ethanol to remove the sulfur introduced during the synthesis process and the excess tar attached to the surface of the carbon microspheres, and then dried at 60°C to obtain the carbon microspheres ( 6M / carbon microspheres) catalyst.

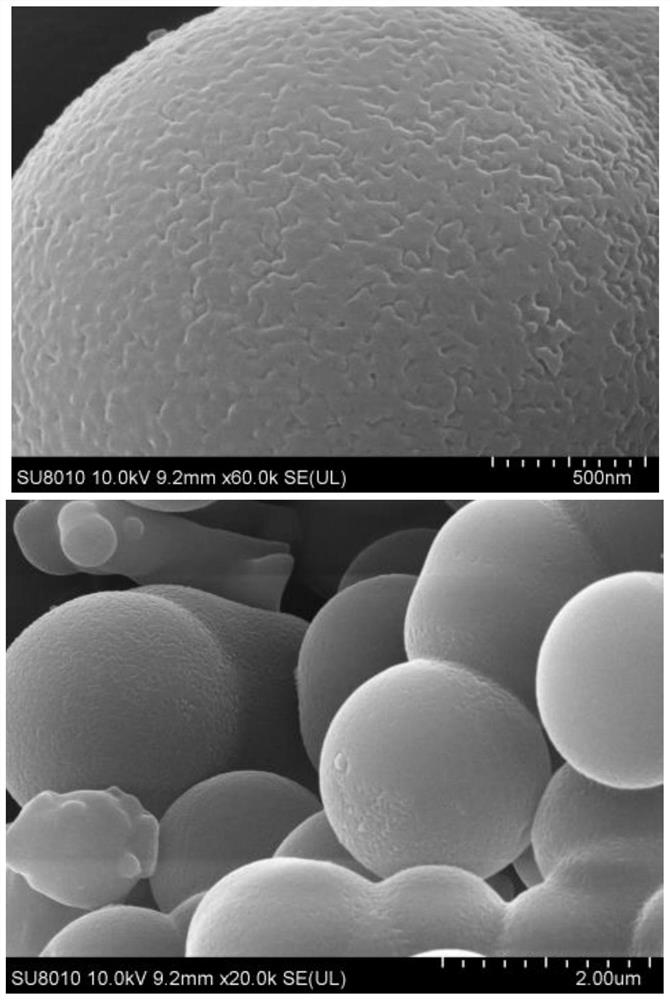

[0036] In order to verify the morphology of the synthesized catalysts, SEM characterization analysis was carried out.

[0037] figure 1 Shown is the SEM image of carbon microspheres prepared by 6mol / L sulfuric acid solution. It can be observed from the figure that the carbon source provided by glucose has basically formed carbon microspheres, and the surface of carbon microspheres has relatively abundant pores, which can provide The effe...

example 2

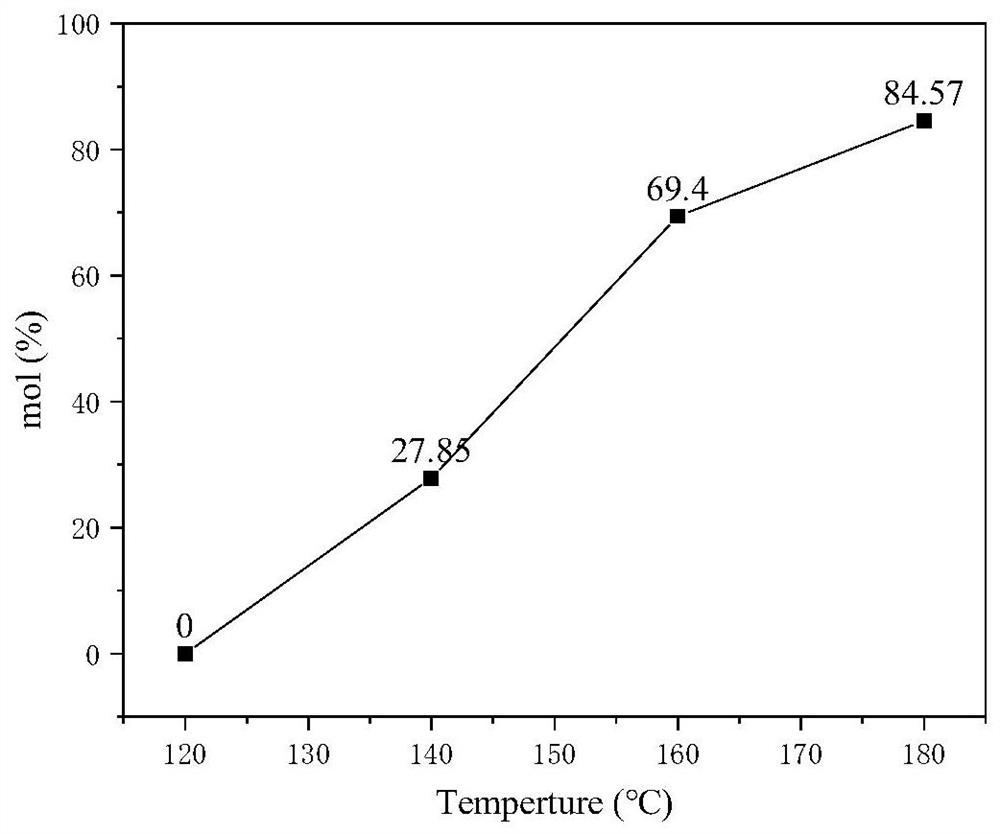

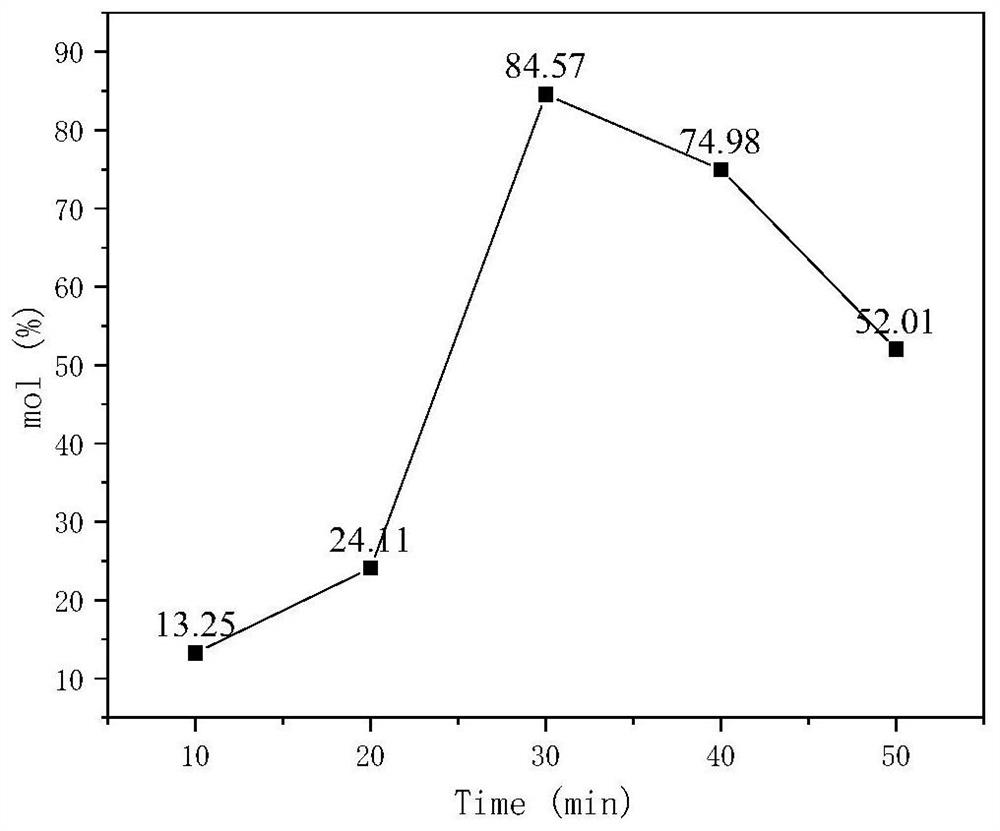

[0039] Add 0.9g of fructose, 0.1g of carbon microspheres and 10ml of deionized water into a microwave reactor, the microwave power is 50W, the reaction time range is 10-50min, and the reaction temperature range is 120-180°C. Microwave assisted temperature rise, and the product was obtained after a period of reaction. Filtration to obtain catalyst and filtrate. The catalyst was washed with deionized water and acetone several times until the filtrate did not change color, and then dried for the next use; the filtrate was sampled for HPLC detection. The result obtained is as Figure 2-6 Shown:

[0040] Figure 2-6 Shown is the effect of reaction conditions on the preparation of HMF from fructose liquefaction catalyzed by carbon microspheres microwave, figure 2 Shown is the change of HMF conversion under the influence of reaction temperature, as can be seen from the figure, with the gradual increase of temperature, the HMF yield increases gradually, and reaches the maximum va...

example 3

[0042] Add 0.05mol (0.9g) of fructose, 0.1g of catalyst and 10ml of deionized water into the microwave reactor, the microwave power is 50W, the reaction temperature is the highest temperature, and the reaction time is 30min. After the reaction is over, the product is obtained, filtered, and obtained catalyst and filtrate. The catalyst was washed with deionized water and acetone several times and then dried for the next use; the filtrate was sampled for HPLC detection. The results obtained are shown in Table 1 and Figure 7 , Figure 8 Shown:

[0043]Table 1 The effect of catalyst types on the preparation of HMF by microwave catalyzed liquefaction of fructose

[0044]

[0045] It can be seen from Table 1 that when using carbon microspheres prepared at 6 mol / L as the catalyst, the HMF yield is the largest at 84.57 mol%, while using carbon microspheres prepared at 3 mol / L as the catalyst, the HMF yield is only 6M / carbon microspheres Half of the yield of HMF was 48.41mol%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com