Passivating agent, passivating method thereof and method for preparing semiconductor film

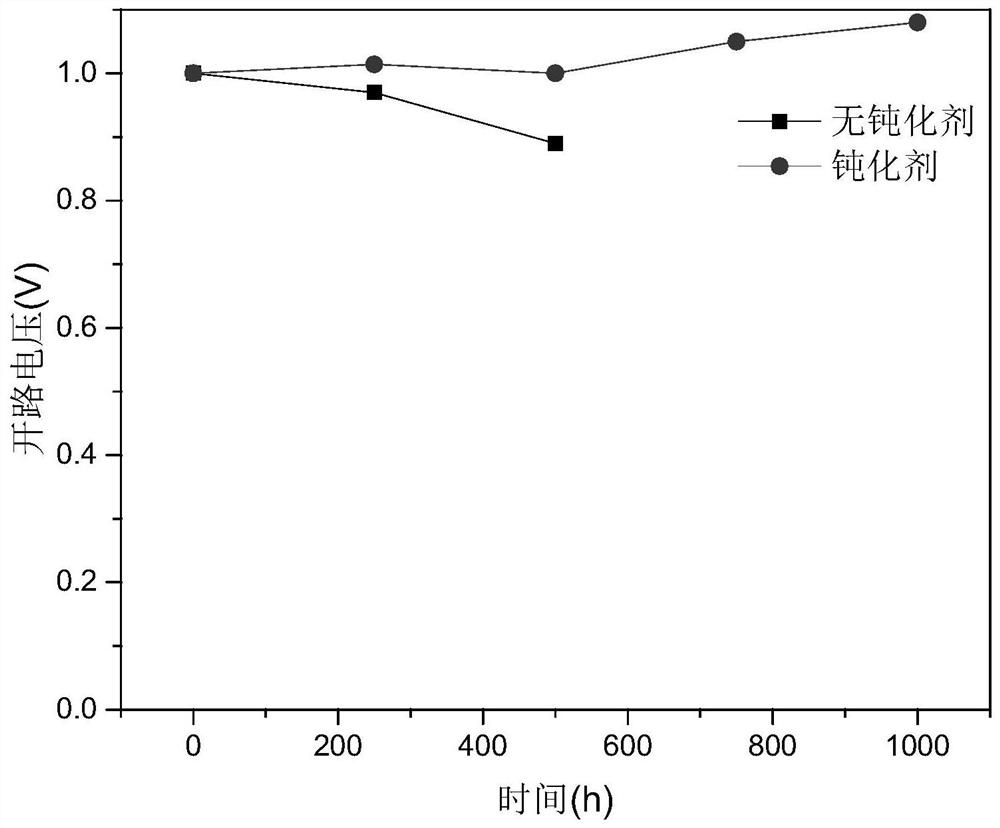

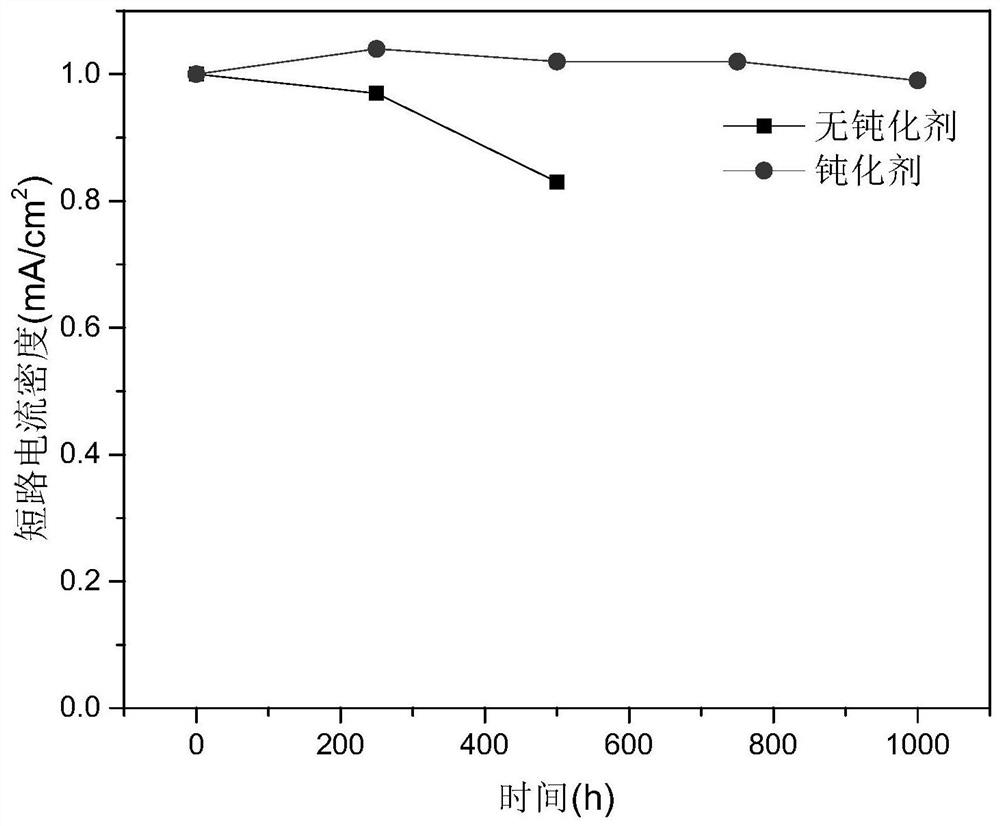

A passivating agent, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of battery hysteresis effect device performance deterioration, etc., to improve the quality, uniformity and repeatability of semiconductor film formation performance, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 of a preparation method of a perovskite layer solar cell of the present invention comprises the following steps:

[0070] (1) Clean the ITO transparent conductive glass, treat the surface with plasma, and set aside.

[0071] (2) CuI hole transport layer was prepared on ITO by slit coating method with a thickness of 30nm.

[0072] (3) Add the passivating agent—1-octyl-3-methylimidazolium bromide salt into methanol solvent to prepare a solution with a mass-volume ratio of 1 mg / mL. The solution was evenly coated on the surface of the hole transport layer material, and then baked at 100 degrees for 5 minutes.

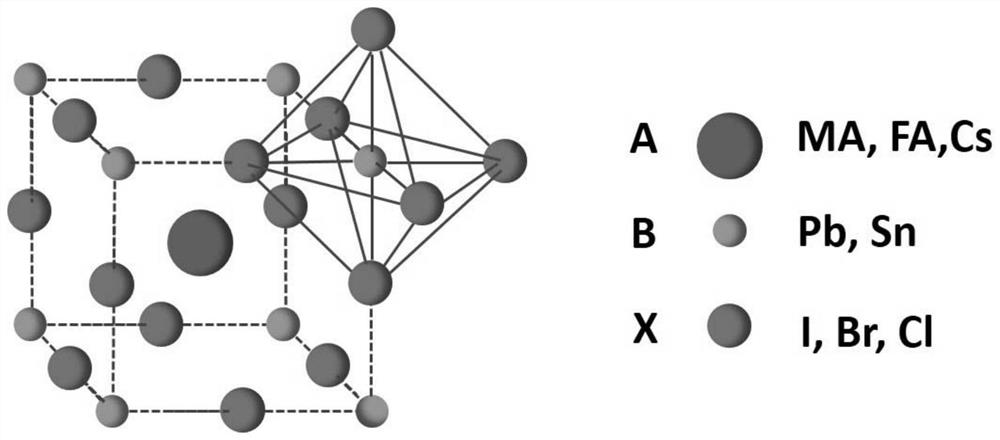

[0073] (4) Prepare the perovskite layer on the hole transport layer coated with passivating agent, adopt the co-evaporation method, and obtain the FAMACsPb(I) with a thickness of 500nm X Br 1-X ) 3 Perovskite thin film layer.

[0074] (5) The electron transport layer PCBM was prepared on the perovskite thin film layer, and a PCBM layer with a thickn...

Embodiment 2

[0077] Embodiment 2 of a preparation method of a perovskite layer solar cell of the present invention comprises the following steps:

[0078] (1) Clean the ITO transparent conductive glass, treat the surface with plasma, and set aside.

[0079] (2) CuI hole transport layer was prepared on ITO by slit coating method with a thickness of 30nm.

[0080] (3) The perovskite layer was prepared on the hole transport layer, and the co-evaporation method was used to obtain FAMACsPb(I) with a thickness of 500nm. X Br 1-X ) 3 Perovskite thin film layer.

[0081] (4) Add the passivating agent—1-octyl-3-methylimidazolium bromide salt into methanol solvent to prepare a solution with a mass-volume ratio of 1 mg / mL. The solution is evenly coated on the perovskite film layer, and then baked at 100 degrees for 5 minutes.

[0082] (5) The electron transport layer PCBM was prepared on the perovskite thin film layer, and a PCBM layer with a thickness of 10 nm was obtained by using a slit coati...

Embodiment 3

[0085] Embodiment 3 of a preparation method of a perovskite layer solar cell of the present invention comprises the following steps:

[0086] (1) Clean the ITO transparent conductive glass, treat the surface with plasma, and set aside.

[0087] (2) NiO hole transport layer was prepared on ITO by slot coating method with a thickness of 30nm.

[0088] (3) Add the passivating agent—1-hexyl-2,3-dimethylimidazolium tetrafluoroborate into the perovskite precursor solution PS, the molar ratio of the passivating agent to the total amount of halogen in the solution PS 1:1000, mix well.

[0089] (4) On the hole transport layer, the solution PS obtained in step (3) is used to prepare a perovskite layer, and the doctor blade coating method is used to obtain FAMACsPb(I X Br 1-X ) 3 Perovskite.

[0090] (5) The electron transport layer ZnO was prepared on the perovskite thin film layer, and a ZnO layer with a thickness of 100 nm was obtained by spraying.

[0091] (6) An electrode laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com