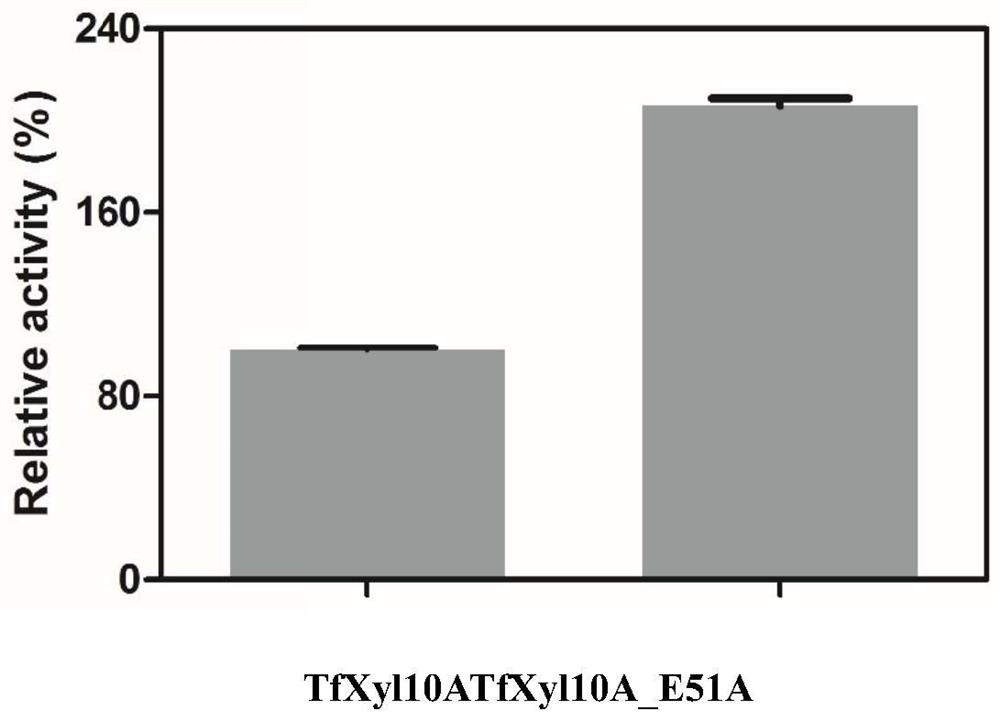

A kind of mutant heat-resistant and alkali-resistant xylanase for papermaking and its application

A technology of xylanase and xylan, which is applied in the field of genetic engineering, can solve problems such as shortening the process flow, and achieve the effects of reducing cost, reducing use, and reducing kappa value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the mutation of xylanase TfXyl10A and the construction of recombinant vector

[0023] (1) Obtain the xylanase TfXyl10A gene from the NCBI database, connect the TfXyl10A gene and the plasmid blunt-e1 (pEASY blunt-e1) to obtain the blunt-e1-TfXyl10A plasmid, the nucleoside of the blunt-e1-TfXyl10A plasmid The acid sequence is shown in SEQ ID No.3. Using the above-mentioned recombinant plasmid as a template, design mutation primers for site-directed mutation. The primer sequences are as follows:

[0024] E51A-sense: AGATGAAGTGGGCGTCGCTGGAG;

[0025] E51A-antisense: CCAGCGACGCCCACTTCATCTCG;

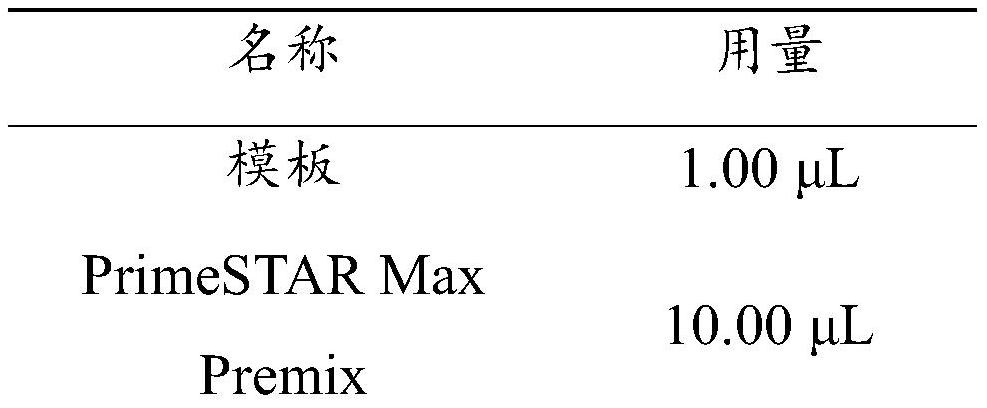

[0026] The PCR amplification reaction system is as follows:

[0027]

[0028]

[0029] The reaction procedure is as follows:

[0030] Preheating, 94°C, 5min; denaturation, 94°C, 30s; annealing, 55-65°C, 30s; 30cycles; extension, 72°C, 2min; re-extension, 72°C, 10min; 4°C, forever.

[0031] (2) Take 3 μL of the PCR product for agarose gel electrophoresis verific...

Embodiment 2

[0039] Embodiment 2, construction contains the recombinant engineered bacterium of above-mentioned mutant gene TfXyl10A_1

[0040] In this example, the recombinant engineering bacteria containing the above-mentioned mutant gene TfXyl10A_1 were constructed, and the specific steps were as follows: add 2 μL of the above-mentioned mutant plasmid blunt-e1-TfXyl10A-E51A with correct sequencing to 50 μL of Escherichia coli BL-21 competent cells, and ice bath for 30 minutes; 42 Heat shock at ℃ for 90 s; ice bath for 2 min, add 1 mL of liquid LB, incubate in a shaker at 37 °C for 1-1.5 h; centrifuge at 8000 rpm for 2 min, discard the supernatant (leave a little bottom liquid). Spread the remaining solution on an LB plate containing 100 μg / mL ampicillin, spread evenly until dry, and incubate overnight at 37°C; pick a single clone the next day and inoculate it in 5 mL of LB medium containing 100 μg / mL ampicillin , 37°C and 200rpm for overnight culture to obtain recombinant engineering ba...

Embodiment 3

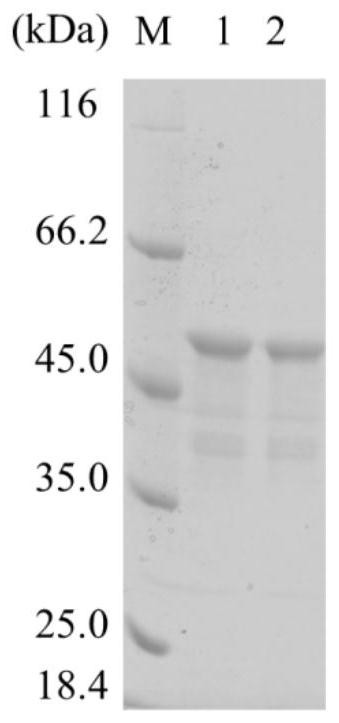

[0041] Embodiment 3: Recombinant expression of mutant gene TfXyl10A_1

[0042] Fermentative expression and purification of the mutant xylanase TfXyl10A_E51A encoded by the above mutant gene TfXyl10A_1, the specific steps are as follows:

[0043] (1) Heterologous expression of recombinant protein:

[0044] Get the recombinant engineered bacterium containing the above-mentioned mutant gene TfXyl10A-1 obtained in Example 2, and cultivate overnight at 37° C. at 200 rpm in 5 mL LB medium (containing 100 μg / mL ampicillin);

[0045] Transfer the cultured bacterial solution overnight to a 1L Erlenmeyer flask containing 300mL LB medium (containing 100μg / mL ampicillin), and culture at 37°C for about 3 hours until OD600=0.6-0.8; the final concentration of adding is 0.5mM IPTG, induced at 20°C for 20h; 8000rpm, centrifuged at 4°C for 10min, to obtain bacterial pellet;

[0046] NaH at pH 8.0 2 PO 4 -Resuspend the bacteria in NaCl buffer, put the bacteria in a 100mL centrifuge tube; put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com