Preparation method of high-strength lithium ion battery silicon alloy composite anode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low mechanical strength and achieve the effects of excellent electrochemical performance, high mechanical elasticity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a high-strength lithium-ion battery silicon alloy composite negative electrode material, comprising the following steps:

[0033] (1) Mix ferrosilicon alloy powder, silicon nanopowder, carbon material, polyacrylonitrile, pullulan gum or Glen gum and N,N-dimethylformamide to form a mixed slurry, each group in the negative electrode material The mass percentages are: ferrosilicon alloy powder 10-20%, silicon nano-powder 25-45%, carbon material (one or more of graphene, carbon black, carbon nanotube or conductive graphite) 15-25% , Polyacrylonitrile 15-25%, pullulan gum or Glen gum 5-10%, N,N-dimethylformamide 5-15%.

[0034] (2), pulverizing the mixed slurry described in step (1);

[0035] (3), the solution obtained in step (2) is ground, and the grinding beads are zirconium beads, and N,N-dimethylformamide is added during the grinding process;

[0036] (4), and then apply the slurry obtained by grinding in step (3) on the copper foil, the thickne...

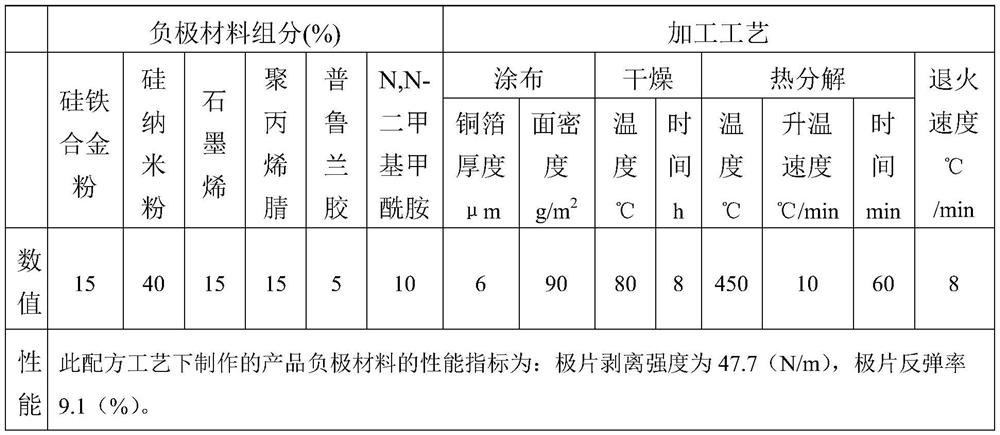

Embodiment 1

[0041]

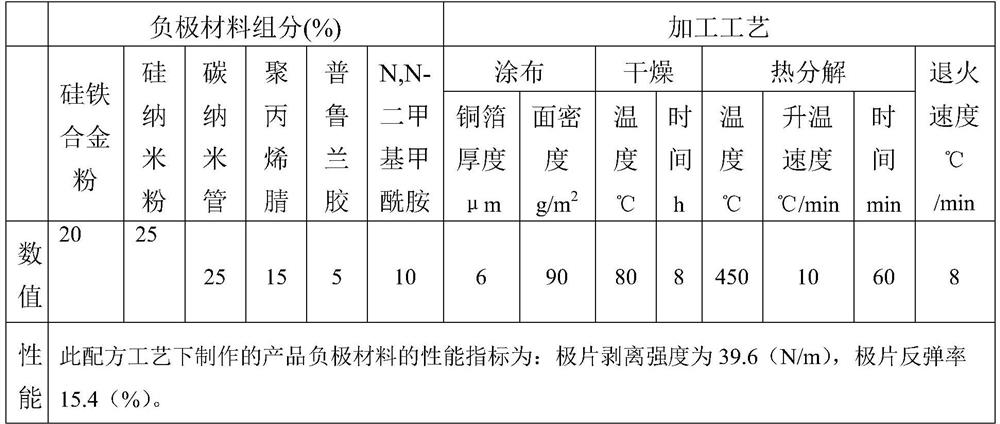

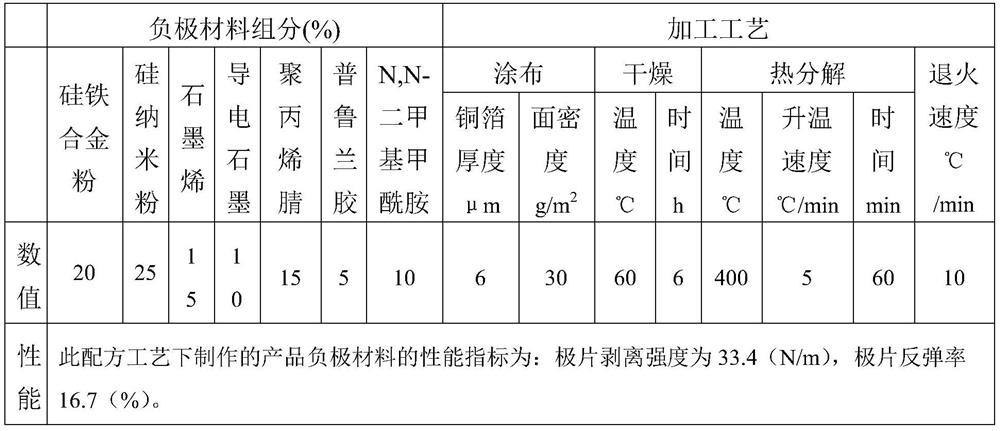

Embodiment 2

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com