A method for improving the mechanical properties of automobile panels

A technology for automobile panels and panels, applied in the direction of reducing gas emissions, can solve the problems of poor tempering stability, increased costs, increased welding, etc., and achieve the effects of performance balance improvement, reduced segregation, and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

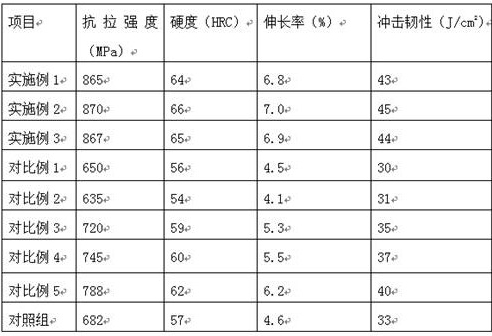

Examples

Embodiment 1

[0018] A method for improving the mechanical properties of automobile panels. In the processing of automobile panels, the prepared inorganic nanopowder is added to the base alloy melt of the panel, and the addition amount is 0.012% of the mass fraction of the alloy melt. Melting and mixing Uniform, pouring molding then, be processed into automobile cover part; The preparation method of described inorganic nanopowder comprises the following steps:

[0019] (1) Put 0.25 moles of chromium trioxide powder in a beaker, add 100 ml of potassium bromate solution, heat in a constant temperature water bath at 60°C, stir and dissolve at 300 rpm for 30 minutes, add 20 ml of ethanol, and stir After uniformity, add 5 ml of hydrochloric acid solution dropwise, age in a closed thermostat for 2 days, place the aged mixed solution in a drying cylinder in a supercritical drying oven, set the temperature at 2°C, feed in liquid carbon dioxide, replace and remove Ethanol and water, then slowly rele...

Embodiment 2

[0028] A method for improving the mechanical properties of automobile panels. In the processing of automobile panels, the prepared inorganic nanopowder is added to the base alloy melt of the panel, and the addition amount is 0.013% of the mass fraction of the alloy melt. Melting and mixing Uniform, pouring molding then, be processed into automobile cover part; The preparation method of described inorganic nanopowder comprises the following steps:

[0029] (1) Put 0.26 moles of chromium trioxide powder in a beaker, add 105 ml of potassium bromate solution, heat in a constant temperature water bath at 65°C, stir and dissolve at 330 rpm for 35 minutes, add 25 ml of ethanol, and stir After uniformity, add 5.5 ml of hydrochloric acid solution dropwise, age in a closed thermostat for 2 days, place the aged mixed solution in a drying cylinder in a supercritical drying oven, set the temperature at 3°C, feed in liquid carbon dioxide, replace and remove Ethanol and water, then slowly re...

Embodiment 3

[0038]A method for improving the mechanical properties of automobile panels. In the processing of automobile panels, the prepared inorganic nanopowder is added to the base alloy melt of the panel, and the addition amount is 0.014% of the mass fraction of the alloy melt. Melting and mixing Uniform, pouring molding then, be processed into automobile cover part; The preparation method of described inorganic nanopowder comprises the following steps:

[0039] (1) Put 0.27 moles of chromium trioxide powder in a beaker, add 110 ml of potassium bromate solution, heat in a constant temperature water bath at 70°C, stir and dissolve at 350 rpm for 40 minutes, add 30 ml of ethanol, and stir After uniformity, add 6 ml of hydrochloric acid solution dropwise, age in a closed thermostat for 3 days, place the aged mixed solution in a drying cylinder in a supercritical drying oven, set the temperature at 4°C, feed in liquid carbon dioxide, replace and remove Ethanol and water, then slowly relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com