Flexible self-supporting vanadium-based heterojunction/graphene composite material as well as preparation method and application thereof

A composite material and heterojunction technology, applied in the field of flexible self-supporting vanadium-based heterojunction/graphene composite material and its preparation, can solve the problems of cumbersome process, long cycle, unsuitable for large-scale production, etc. Effect of nucleation and transformation, short preparation cycle, and excellent catalytic transformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A flexible self-supporting vanadium-based heterojunction / graphene composite material, the preparation method of which comprises the steps of:

[0038] 1) Dissolve 0.56g of vanadium pentoxide and 5mL of 30wt% hydrogen peroxide solution in 30mL of deionized water, sonicate until the solution turns brownish red; pour the resulting brownish red solution into a 40mL reaction kettle and heat it at 190°C React for 20h; get vanadium pentoxide gel;

[0039] 2) Mix the obtained vanadium pentoxide gel with 40 mL of graphene oxide solution with a concentration of 8 mg / mL, stir and sonicate; then freeze with liquid nitrogen, and then freeze-dry to obtain a precursor material;

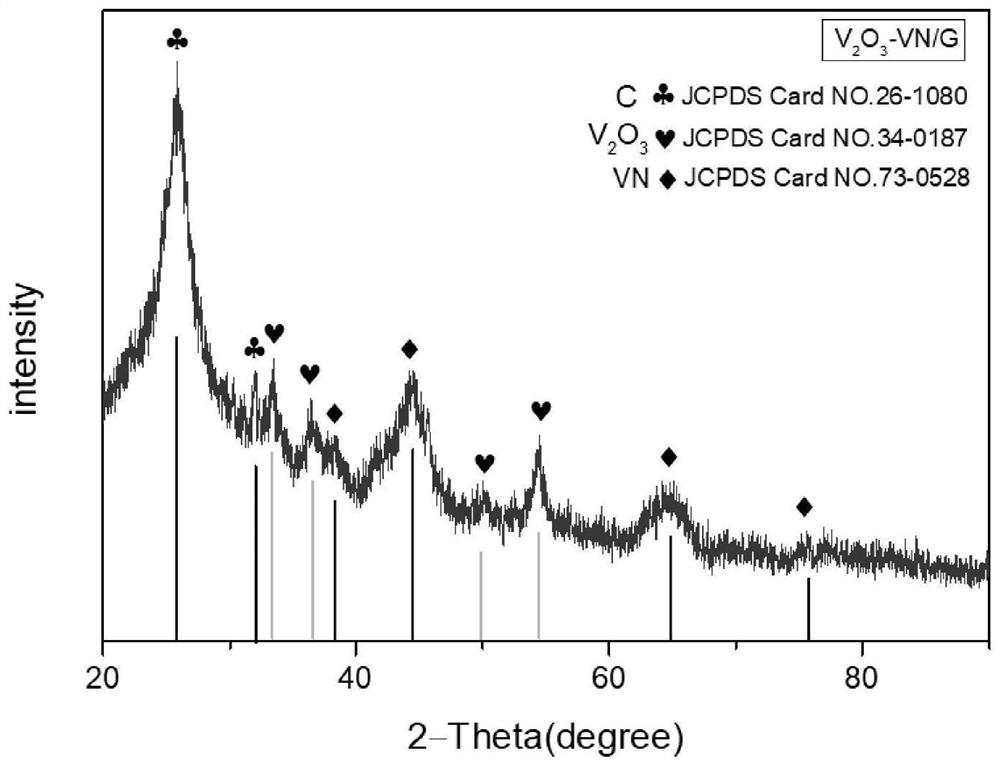

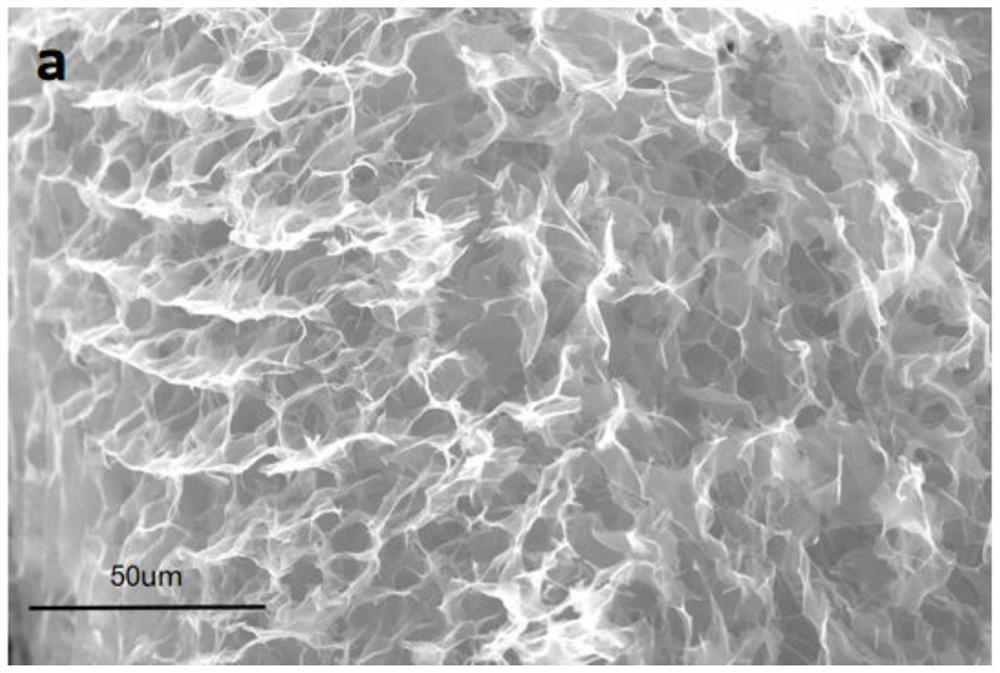

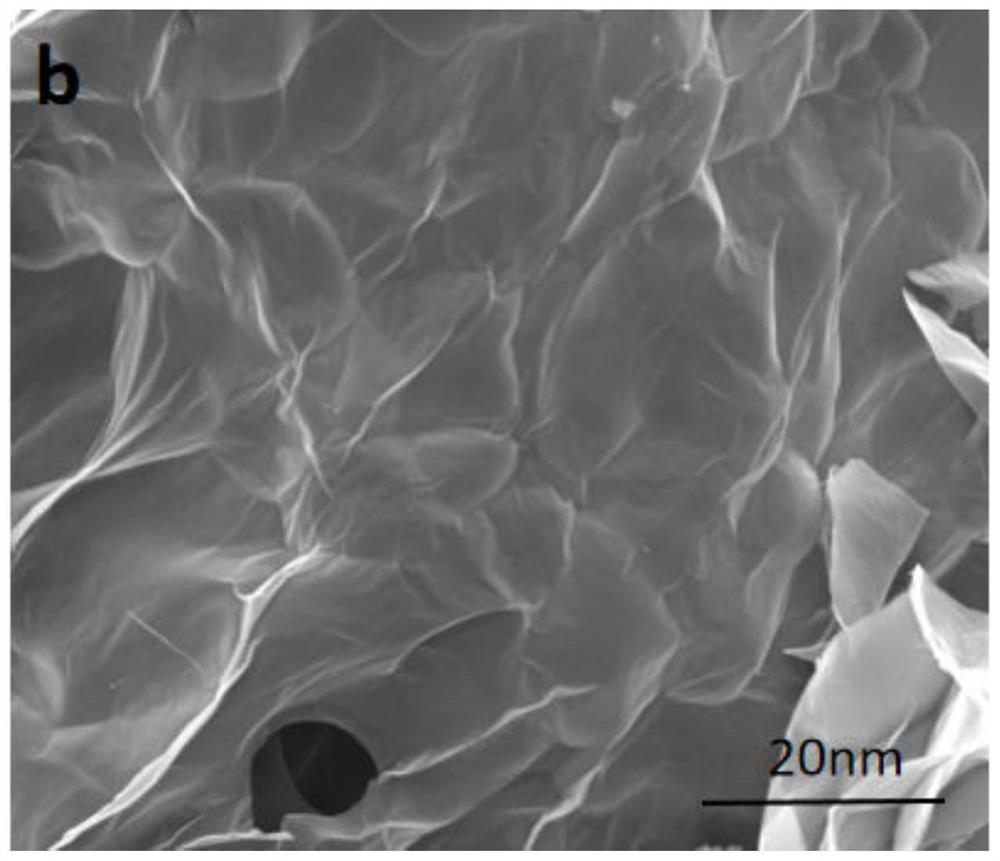

[0040] 3) Cut and press the obtained precursor material into thin slices with a diameter of 10 mm, heat-preserve at 550°C and ammonia atmosphere for 20 minutes, then replace with argon, and heat-preserve for 100 minutes under an argon atmosphere; after cooling to room temperature, a three-dimensional porous S...

Embodiment 2

[0049] A flexible self-supporting vanadium-based heterojunction / graphene composite material, the preparation method of which comprises the steps of:

[0050] 1) Dissolve 0.23g of vanadium pentoxide and 5mL of 30wt% hydrogen peroxide solution in 30mL of deionized water, sonicate until the solution turns brown-red; pour the resulting brown-red solution into a 40mL reactor and heat it at 190°C React for 20h; get vanadium pentoxide gel;

[0051] 2) Mix the obtained vanadium pentoxide gel with 20 mL of a graphene oxide solution with a concentration of 5 mg / mL, stir and sonicate; then freeze with liquid nitrogen, and then freeze-dry to obtain a precursor material;

[0052] 3) Cut and press the obtained precursor material into thin slices with a diameter of 10 mm, heat-preserve at 550°C and ammonia atmosphere for 20 minutes, then replace with argon, and heat-preserve for 100 minutes under an argon atmosphere; after cooling to room temperature, a three-dimensional porous Flexible sel...

Embodiment 3

[0055] A flexible self-supporting vanadium-based heterojunction / graphene composite material, the preparation method of which comprises the steps of:

[0056] 1) Dissolve 0.23g of vanadium pentoxide and 5mL of 30wt% hydrogen peroxide solution in 30mL of deionized water, sonicate until the solution turns brown-red; pour the resulting brown-red solution into a 40mL reactor and heat it at 190°C React for 20h; get vanadium pentoxide gel;

[0057] 2) Mix the obtained vanadium pentoxide gel with 20 mL of a graphene oxide solution with a concentration of 5 mg / mL, stir and sonicate; then freeze with liquid nitrogen, and then freeze-dry to obtain a precursor material;

[0058] 3) Cut and press the obtained precursor material into thin slices with a diameter of 10 mm, heat-preserve at 550°C and ammonia atmosphere for 30 minutes, then replace with argon, and heat-preserve for 100 minutes under an argon atmosphere; after cooling to room temperature, a three-dimensional porous Flexible sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com