Compound sulfachlorpyridazine sodium powder and preparation method thereof

The technology of sulfachlordazine sodium and chlordazine sodium powder is applied in the field of compound sulfachlordazine sodium powder and preparation thereof, and can solve the problems of not being able to exert maximum curative effect, reducing animal absorption rate, reducing bioavailability and the like, and achieving The effect of improving bioavailability, improving palatability, and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

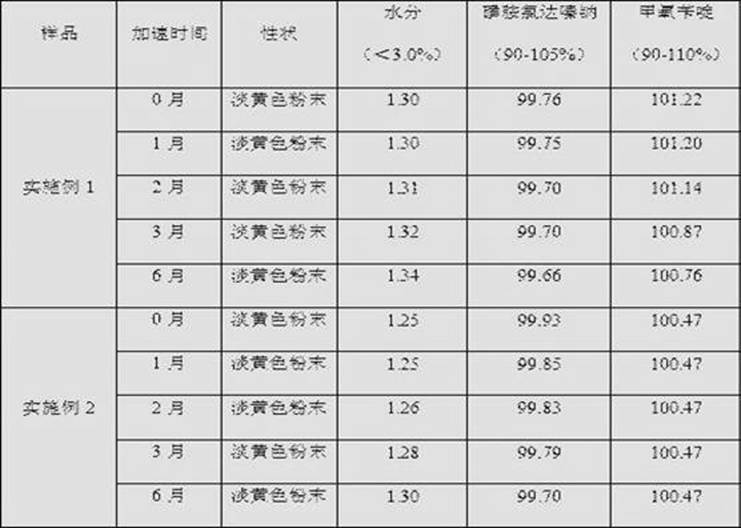

Examples

Embodiment 1

[0027] A kind of compound sulfachlordazine sodium powder of the present embodiment, every 100g includes raw materials: 62.5g of sulfachlordazine sodium, 12.5g of trimethoprim, 2g of poloxamer, 15g of beta cyclodextrin, sucrose 8g.

[0028] The method for preparing above-mentioned compound recipe sulfachlorperazine sodium powder is carried out according to the following steps:

[0029] (1) Dry beta-cyclodextrin at 105°C for 8 hours, and control the weight loss on drying within 3.0%;

[0030] (2) Weigh the dried beta-cyclodextrin, dissolve it in an appropriate amount of hot water at 60°C, add 2g of poloxamer, and stir evenly;

[0031] (3) Add the prescribed amount of sulfa synergist, keep the temperature at 60°C, and stir to dissolve;

[0032] (4) After the sulfa synergist is completely dissolved, take the prescribed amount of sulfachlordazine sodium and filler, and stir to dissolve;

[0033] (5) Turn on the machine to preheat the spray tower, set the parameters and spray dry...

Embodiment 2

[0036] A kind of compound sulfachlordazine sodium powder of the present embodiment, every 100g includes raw materials: sulfachlordazine sodium 62.5g, trimethoprim 12.5g, polysorbate 80 2g, beta cyclodextrin 13g, sucrose 10g.

[0037] The method for preparing above-mentioned compound recipe sulfachlorperazine sodium powder is carried out according to the following steps:

[0038] (1) Dry beta-cyclodextrin at 105°C for 12 hours, and control the weight loss on drying within 1.0%;

[0039] (2) Weigh the dried beta-cyclodextrin, dissolve it in an appropriate amount of hot water at 60°C, add 2g of polysorbate 80, and stir evenly;

[0040] (3) Add the prescribed amount of sulfa synergist, keep the temperature at 60°C, and stir to dissolve;

[0041] (4) After the sulfa synergist is completely dissolved, take the prescribed amount of sulfachlordazine sodium and filler, and stir to dissolve;

[0042] (5) Turn on the machine to preheat the spray tower, set the parameters and spray dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com