Preparation method of chitosan-loaded ciprofloxacin microsphere

The technology of chitosan and carrier ring is applied in the field of preparation of microsphere drug-carrying sustained-release system, which can solve the problems of poor bacteriostatic persistence and the like, and achieve the effects of good antibacterial properties, simple and easy operation, and excellent sustained-release performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 0.4g of chitosan powder with a molecular weight of 100,000 in 40ml of 1% acetic acid solution, add ciprofloxacin according to the mass ratio of chitosan and ciprofloxacin at 1:1, fully dissolve, and then add 5ml of Span 80 was dissolved in 120ml of liquid paraffin and dissolved completely by ultrasonication respectively. Mix the two solutions and stir and emulsify for 30min under the conditions of stirring speed 500rmp and water bath 60°C, slowly add 5ml of 50% glutaraldehyde dropwise, continue stirring and crosslinking at 500rmp and water bath 60°C for 2h, and centrifuge the obtained suspension. The obtained precipitates were washed with petroleum ether and isopropanol, centrifuged several times, and the product was dried in an oven at 80° C., and then ground with a mortar to obtain the final product chitosan-loaded ciprofloxacin microspheres.

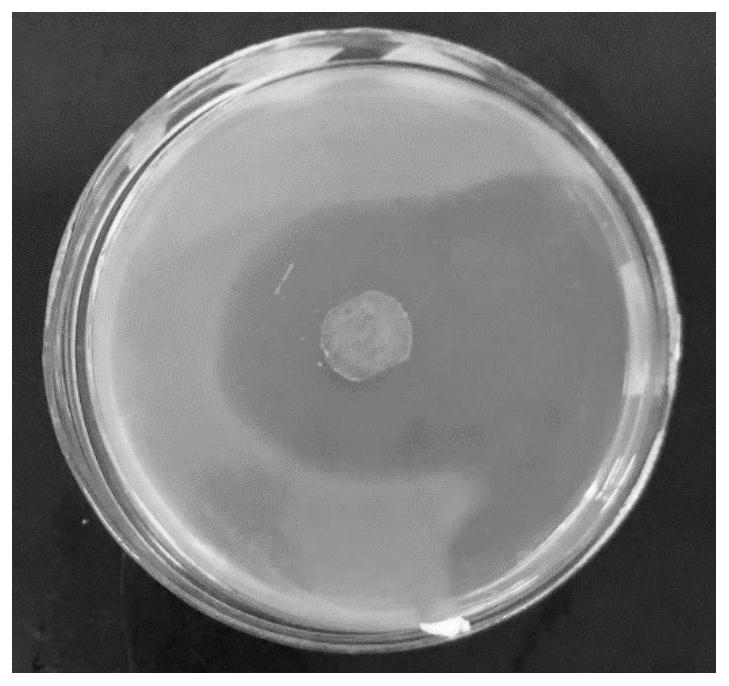

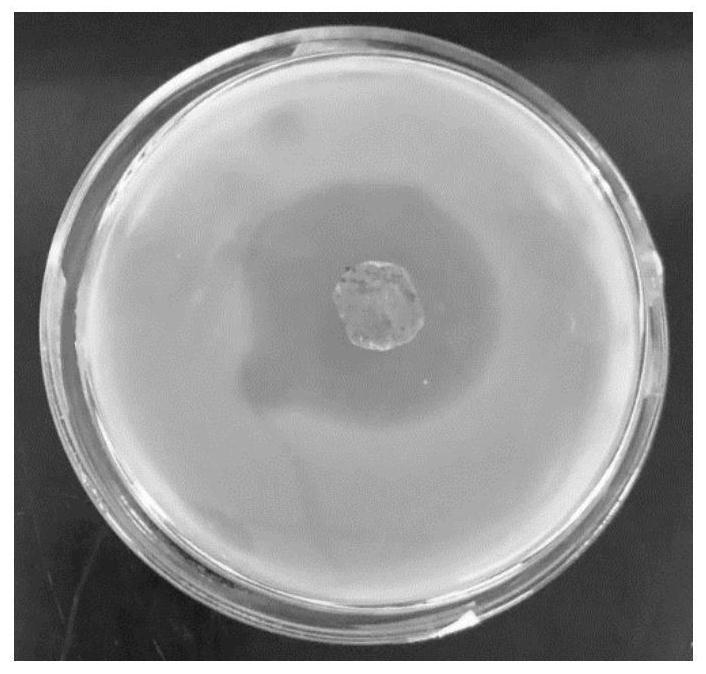

[0035] figure 2 It is the antibacterial effect diagram of 0.01 g of chitosan-loaded ciprofloxacin microspheres (ch...

Embodiment 2

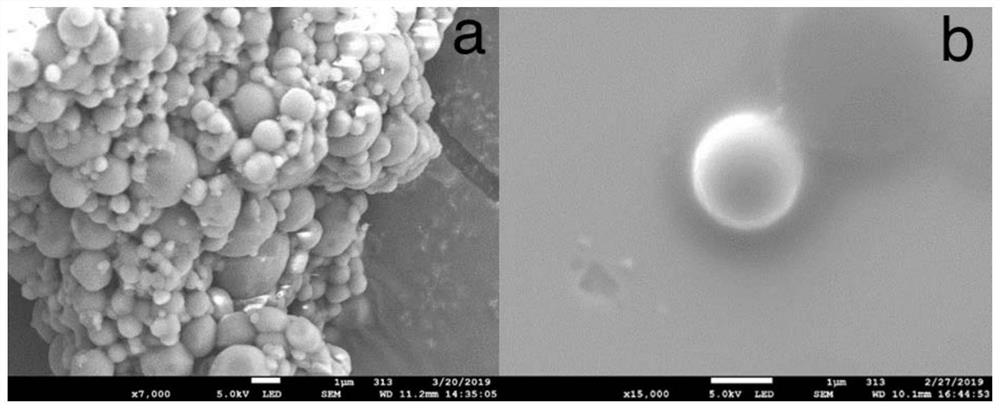

[0037] Change the mass ratio of chitosan / ciprofloxacin in Example 1 to 2:1 and 4:1 respectively, and the other steps are the same as in Example 1. figure 1 It is a scanning electron microscope image of chitosan-loaded ciprofloxacin microspheres (chitosan: ciprofloxacin=4:1), wherein the magnification of image a is 7000, and the magnification of image b is 15000. It can be seen from the figure that the particle size of the microspheres is basically distributed between 1-5 μm, which is relatively uniform. The antibacterial effect of chitosan ciprofloxacin microsphere powder with different drug loading ratios on Staphylococcus aureus, image 3 Chitosan: ciprofloxacin = 2: 1, inhibition zone D = 40mm, Figure 4 Chitosan: ciprofloxacin = 4:1, antibacterial zone D = 36mm, it can be seen that with the decrease of the dose of ciprofloxacin, the antibacterial effect is gradually weakened.

Embodiment 3

[0039] This example is basically the same as Example 1, the only difference is that the volume ratio of liquid paraffin and acetic acid solution is 4:1. The SEM image of the prepared chitosan-loaded ciprofloxacin microspheres is as follows Figure 13 As shown, the spherical shape is good, the surface is relatively smooth, and there is less adhesion, which is no obvious difference compared with the 3:1 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com