Hydrogenation catalyst for petroleum resin, preparation method and application thereof

A technology of hydrogenation catalyst and petroleum resin, which is applied in the direction of chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, heterogeneous catalyst chemical elements, etc., which can solve the problem of low investment, high price and unknowable formula to achieve high hydrogenation rate, stable quality index and high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

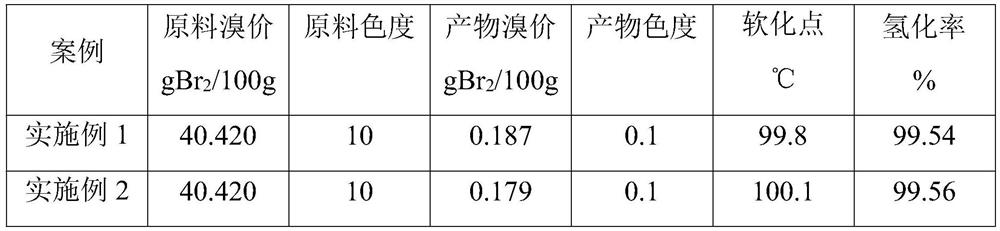

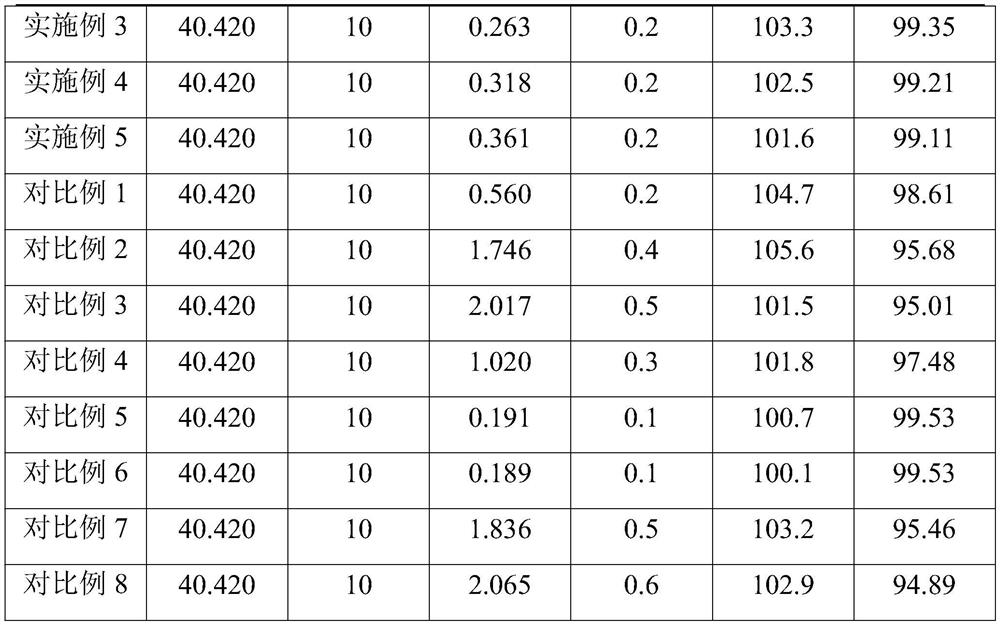

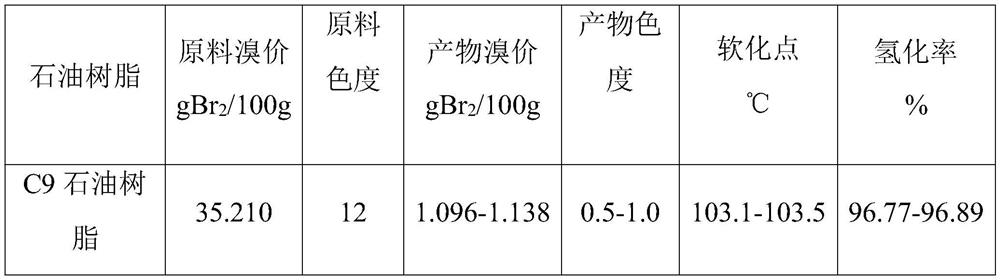

Examples

Embodiment 1

[0028] This embodiment provides a hydrogenation catalyst for petroleum resins, the catalyst uses aluminum oxide, titanium oxide, and cerium oxide as an aluminum oxide-titania-cerium oxide composite carrier, and metal nickel is loaded on the composite carrier, and on the The mass ratio of aluminum oxide, titanium oxide and cerium oxide in the composite carrier is 6:3:1, and the content of metal nickel in the catalyst is 20wt%.

[0029] The preparation method of this hydrogenation catalyst comprises the following steps:

[0030] Step 1. Preparation of alumina-titania-ceria composite carrier:

[0031] (1) Preparation of tetrabutyl titanate-alumina precursor: Dissolve 25.5g of tetrabutyl titanate in 80mL of absolute ethanol, add 12g of alumina and mix evenly, and then prepare ice with a volume ratio of 1:3:1. Acetic acid-ethanol-water solution, and dropwise added to the previous mixed solution, soaked at 40-45°C for 8h to obtain tetrabutyl titanate-alumina precursor;

[0032] (2...

Embodiment 2

[0037] This embodiment provides a hydrogenation catalyst for petroleum resins, the catalyst uses aluminum oxide, titanium oxide, cerium oxide and nickel as active components, wherein aluminum oxide, titanium oxide, and cerium oxide are used as aluminum oxide-titania-oxide A cerium composite carrier on which metal nickel is supported, and the mass ratio of alumina, titanium oxide and cerium oxide in the composite carrier is 7:3:1, and the content of metal nickel in the catalyst is 15wt%. The difference between the preparation method and Example 1 is that the calcination temperature is 650°C.

Embodiment 3

[0039] This embodiment provides a hydrogenation catalyst for petroleum resins, the catalyst uses aluminum oxide, titanium oxide, and cerium oxide as an aluminum oxide-titania-cerium oxide composite carrier, and metal nickel is loaded on the composite carrier, and on the The mass ratio of aluminum oxide, titanium oxide and cerium oxide in the composite carrier is 5:4:1, and the content of metallic nickel in the catalyst is 25 wt%. The difference between the preparation method and Example 1 is: the nickel salt solution is an aqueous solution of nickel acetate; the microwave power of step (4) is 240w, and the microwave heating time is 20min; the conditions for microwave heating in step 2 are: microwave power 400w, microwave pressure of 0.5MPa, microwave time is 20min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com