Wollastonite-loaded strontium and lanthanum solid base catalyst as well as preparation method and application thereof

A technology of solid base catalyst and wollastonite, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve complex process, leaching deactivation, raw oil Higher quality requirements and other issues, to achieve the effect of wide sources, simple and feasible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]In the second aspect, the present invention provides a preparation method of the solid base catalyst, which includes the following steps:

[0027]Add the strontium source, lanthanum source and wollastonite powder to water, stir and immerse;

[0028]The impregnated product is dried, calcined and activated to obtain a solid base catalyst.

[0029]In some embodiments, the strontium source is a compound that is soluble in water and the cation is strontium ion, such as strontium chloride, strontium nitrate and the like.

[0030]In some embodiments, the lanthanum source is a compound that is soluble in water and the cation is a lanthanum ion, such as lanthanum chloride, lanthanum nitrate, and the like.

[0031]In order to reduce the influence of anions on the catalyst preparation process and catalytic effect, the strontium source and the lanthanum source are preferably nitrates.

[0032]In some embodiments, during the dipping process, the concentration of the strontium salt solution is 0.9-0.1 mol / L;...

Embodiment 1

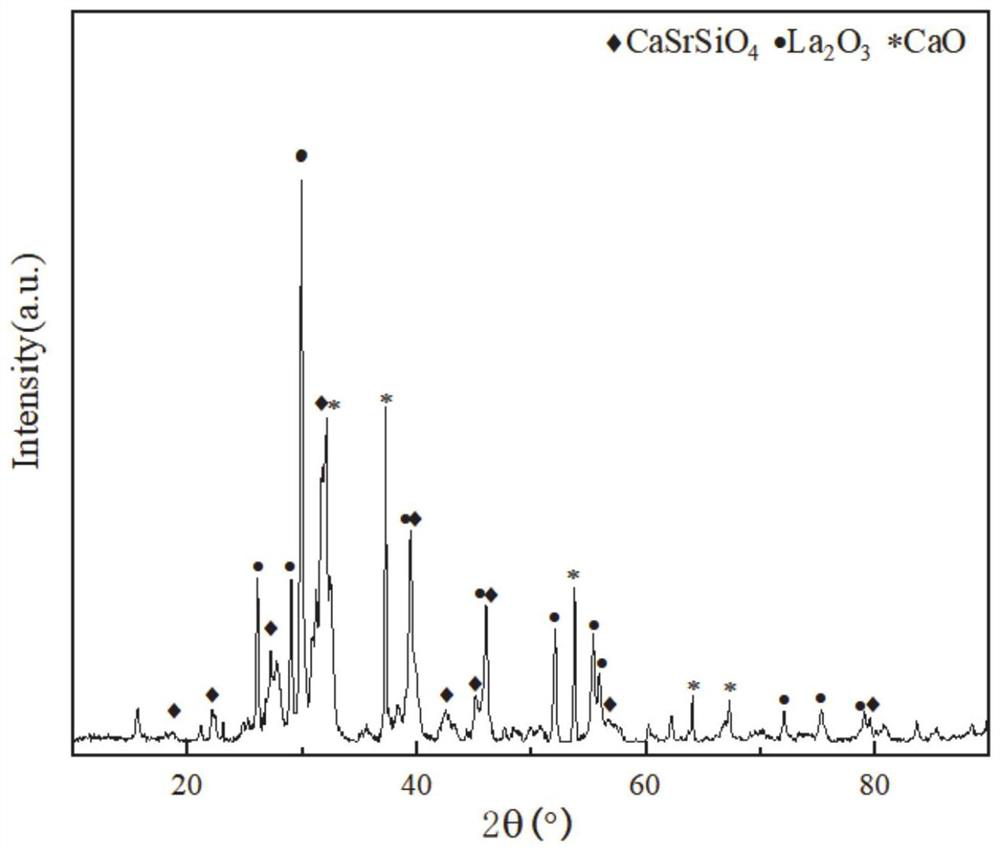

[0050]Weigh 12g natural wollastonite ore powder, 14.81g strontium nitrate (Sr(NO3)2·4H2O) and 9.75g lanthanum nitrate (La(NO3)3·XH2O) Add to 100 mL of deionized water, stir and immerse for 0.5 h to obtain a mixed solution. Put the beaker of the mixed solution into a water bath with a stirring device, and evaporate to dryness in a water bath at 80°C. The obtained catalyst precursor was dried at 120°C for 12 hours, and then heated from 20°C to 900°C at a heating rate of 5°C / min, and then calcined and activated for 5 hours to obtain a wollastonite load with a strontium / lanthanum molar ratio of 7 / 3. Highly stable solid base catalyst of strontium and lanthanum.

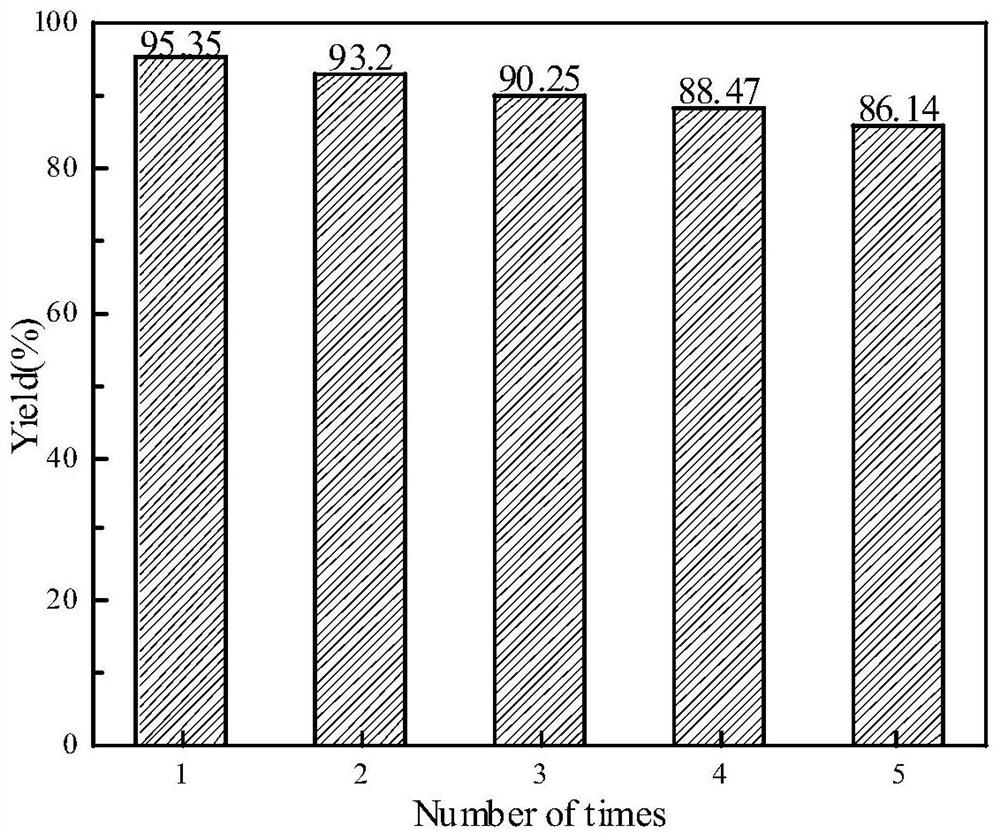

[0051]10.5g methanol, 20g palm oil and 1.6g catalyst were successively added into the autoclave, heated to 150°C and maintained for 3h under continuous stirring at a speed of 1200r / min. Separate the solid catalyst from the reaction product through a centrifuge, pour the liquid product into a separatory funnel, let it stand for sepa...

Embodiment 2

[0056]Weigh 12g natural wollastonite ore powder, 19.05g strontium nitrate (Sr(NO3)2·4H2O) and 3.25g lanthanum nitrate (La(NO3)3·XH2O) Add to 100 mL of deionized water, stir and immerse for 0.5 h to obtain a mixed solution. Put the beaker of the mixed solution into a water bath with a stirring device, and evaporate to dryness in a water bath at 80°C. The obtained catalyst precursor was dried at 120°C for 12 hours, and then heated from 20°C to 900°C at a heating rate of 5°C / min, and then calcined and activated for 5 hours to obtain a wollastonite load with a strontium / lanthanum molar ratio of 9 / 1. Highly stable solid base catalyst of strontium and lanthanum.

[0057]10.5g methanol, 20g palm oil and 1.6g catalyst were successively added into the autoclave, and heated to 150°C and maintained for 3h under continuous stirring at a speed of 1200r / min. Separate the solid catalyst from the reaction product through a centrifuge, pour the liquid product into a separatory funnel, let it stand for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com