Binder and lithium ion battery containing same

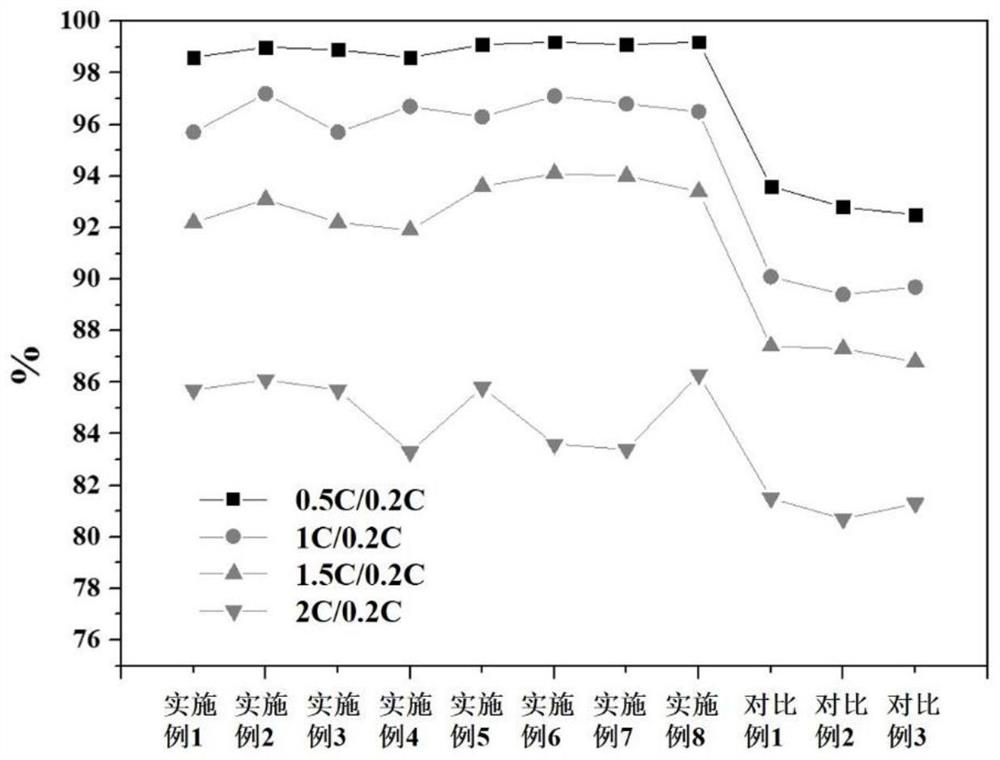

A lithium-ion battery and binder technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor processing performance of pole pieces, limited battery cycle life, failure to fully cover pole pieces, etc., to achieve Low-temperature performance improvement, expansion rate suppression, and effects of low expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] [Preparation method of cross-linked polymer]

[0057] As previously mentioned, the present invention also provides a method for preparing the above-mentioned cross-linked polymer, the method comprising the steps of:

[0058] (1) Make monomer A, monomer B and monomer C polymerize in the solvent system;

[0059] (2) After the completion of the polymerization reaction, adjust the pH value of the system, optionally adding or not adding diamine substances to obtain the cross-linked polymer;

[0060] Wherein, the monomer A, monomer B, monomer C and diamines have the meanings as described above.

[0061] According to an embodiment of the present invention, the mass ratio of monomer A, monomer B and monomer C is (6-8):(1.95-4):(0.001-0.4), for example (6.5-7.5): (2.2~3.5): (0.005~0.3).

[0062] According to an embodiment of the present invention, the solvent in the solvent system is water, such as deionized water.

[0063] According to the embodiment of the present inventio...

Embodiment 1

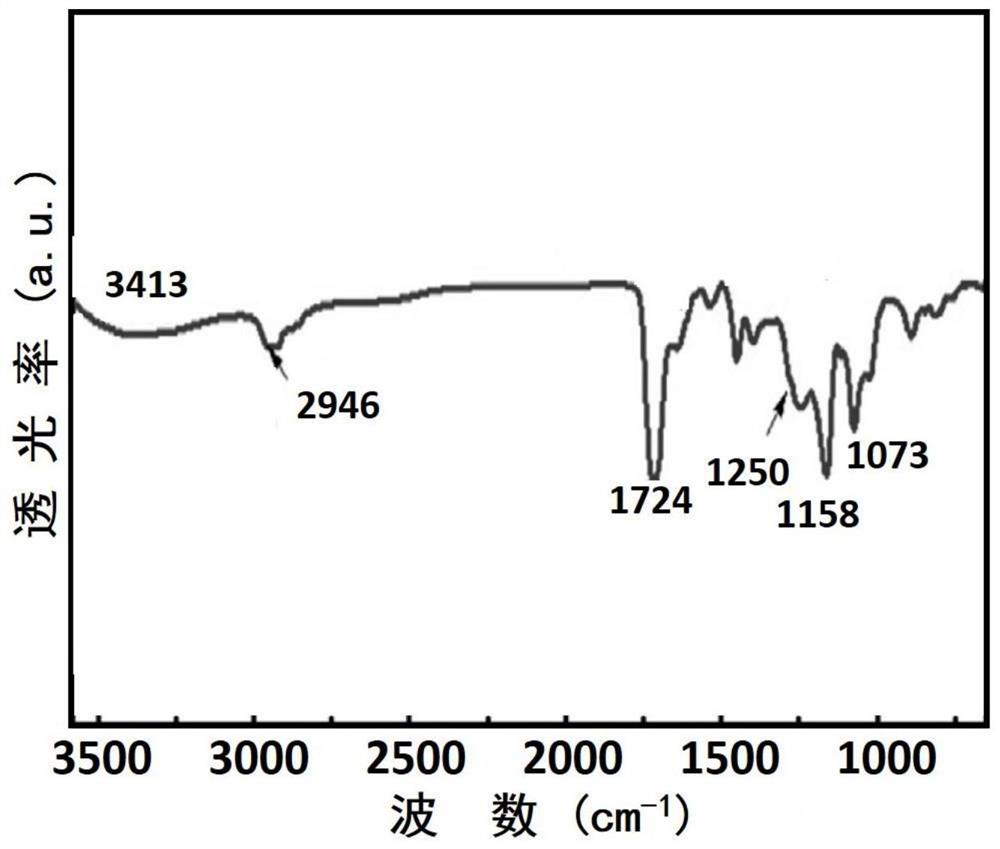

[0139] Preparation of cross-linked soluble polymers:

[0140] (1) Take 10 parts by mass of hydroxyethyl acrylate (monomer A), 0.2 parts by mass of N-methylol acrylamide (monomer C), and 2.5 parts by mass of acrylic acid (monomer B) to 200 parts by mass In deionized water, 800rpm mechanical stirring, nitrogen gas was introduced, the temperature was raised to 40°C, kept for 30min, 0.05 parts by mass of ammonium persulfate and 0.05 parts by mass of tetramethylethylenediamine were added, and reacted for 12 hours.

[0141] (2) Prepare a lithium hydroxide aqueous solution with a concentration of 5wt%, dropwise add it to the reaction system of step (1), adjust the pH to 7, and continue stirring for 2 hours to obtain a cross-linked soluble polymer with a viscosity of 8000mPa·s.

[0142] Each monomer is converted substantially completely, and the prepared polymer has a cross-linked structure of -A-B-C-.

[0143] The solid content of the prepared polymer was 6 wt%, and the weight avera...

Embodiment 2

[0152] Other operations are the same as in Example 1, and the difference is only that the cross-linked soluble polymer is prepared as follows:

[0153] (1) Add 10 parts by mass of hydroxypropyl acrylate, 0.3 parts by mass of N-methylolacrylamide, and 3 parts by mass of acrylic acid to 200 parts by mass of deionized water, stir mechanically at 800 rpm, feed nitrogen, and heat up to 40°C, keep warm for 30min, add 0.05 parts by mass of ammonium persulfate and 0.05 parts by mass of sodium bisulfite, and react for 12 hours.

[0154] (2) be prepared into a lithium hydroxide aqueous solution with a concentration of 5 wt%, dropwise added to the reaction system of step (1), adjust the pH to 7, and continue stirring for 2 hours to obtain a cross-linked soluble polymer with a viscosity of 8700mPa·s , the solid content is 5.8wt%, and the weight average molecular weight is about 650,000.

[0155] The above adhesive was tested, its glass transition temperature was 37°C, and its electrical ...

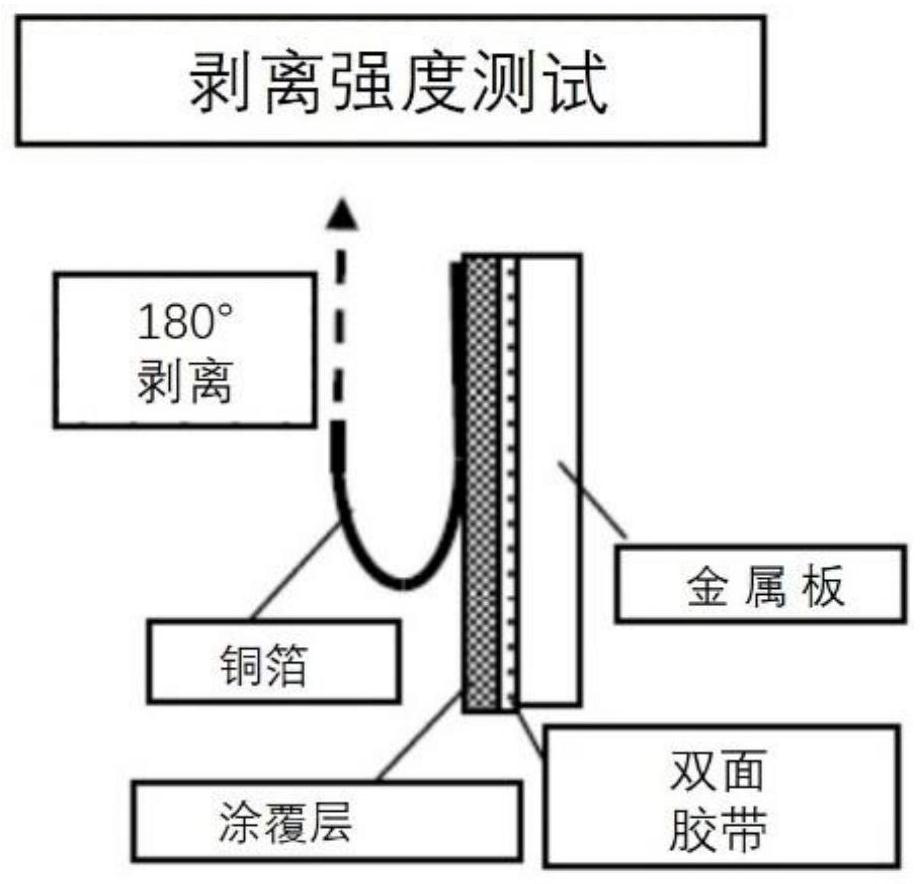

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com