Ball-milling spray regeneration method of waste lithium ion battery positive electrode material

A technology for lithium-ion batteries and cathode materials, which is applied in the field of ball milling spray regeneration of nickel-cobalt-lithium manganese oxide cathode materials for waste lithium-ion batteries. and other problems, to achieve the effect of being conducive to industrialized large-scale production, reducing electrochemical performance, and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

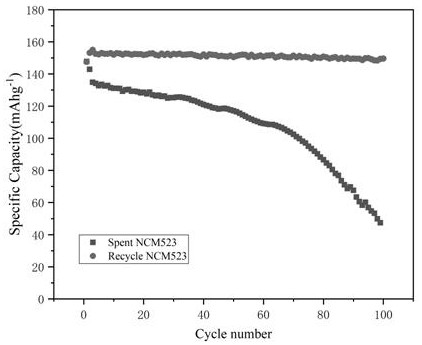

[0032] A ball-milling and spraying regeneration method for positive electrode materials of waste lithium-ion batteries adopts the following steps:

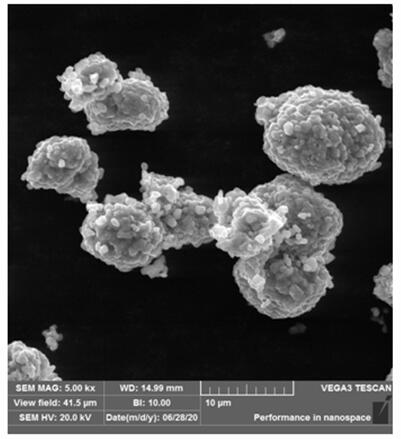

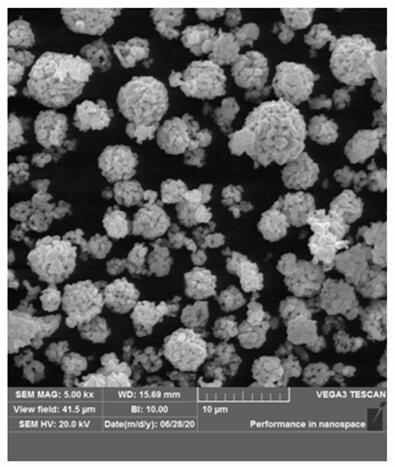

[0033] (1) Immerse the waste lithium-ion battery NCM523 in a NaCl solution with a mass fraction of 5% at room temperature for 24 hours, then manually disassemble and separate the battery case and battery cell, and immerse the positive electrode sheet in a NaOH solution with a concentration of 3mol / L. Peel off the positive electrode material, wash with a sodium hydroxide solution with a concentration of 1.5mol / L at 60°C for more than 3 times to remove residual aluminum, etc., then perform suction filtration to obtain the positive electrode material, and finally calcinate in air at 650°C for 10 hours to remove the aluminum on the surface of the electrode. PVDF and conductive carbon were ground and passed through a 200-mesh sieve to obtain NCM523 positive electrode powder for waste lithium-ion batteries;

[0034] (2) Detect the conte...

Embodiment 2

[0041] A ball-milling and spraying regeneration method for positive electrode materials of waste lithium-ion batteries adopts the following steps:

[0042] (1) Immerse the waste lithium-ion battery NCM622 in a NaCl solution with a mass fraction of 5% at room temperature for 24 hours, then manually disassemble and separate the battery case and battery cell, and immerse the positive electrode sheet in a NaOH solution with a concentration of 3mol / L. Peel off the positive electrode material, wash with a sodium hydroxide solution with a concentration of 1mol / L at 70°C for more than 3 times to remove residual aluminum, etc., then perform suction filtration to obtain the positive electrode material, and finally calcinate at 650°C in air for 10 hours to remove PVDF and Conductive carbon, ground through a 200-mesh sieve to obtain waste lithium-ion battery NCM622 positive electrode powder;

[0043] (2) Detect the content of each element in the positive electrode powder, mix the powder, ...

Embodiment 3

[0050] A ball-milling and spraying regeneration method for positive electrode materials of waste lithium-ion batteries adopts the following steps:

[0051] (1) Immerse the waste lithium-ion battery NCM811 in a NaCl solution with a mass fraction of 5% at room temperature and discharge it for 24 hours, then manually disassemble and separate the battery case and battery cell, and immerse the positive electrode sheet in a NaOH solution with a concentration of 3mol / L. Peel off the positive electrode material, wash with a sodium hydroxide solution with a temperature of 80°C and a concentration of 0.5mol / L for more than 3 times to remove residual aluminum, etc., then perform suction filtration to obtain the positive electrode material, and finally calcine in air at 650°C for 10 hours to remove the electrode surface PVDF and conductive carbon were ground and passed through a 200-mesh sieve to obtain NCM811 positive electrode powder for waste lithium-ion batteries;

[0052] (2) Detect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com