Welding gas mixture without oxygen combustion supporting

A gas mixture, welding gas technology, applied in gas flame welding equipment, gas fuel, welding equipment and other directions, can solve the problems of flame temperature drop, scarce output, low safety of acetylene, etc., achieve uniform heat release, reduce production costs, The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

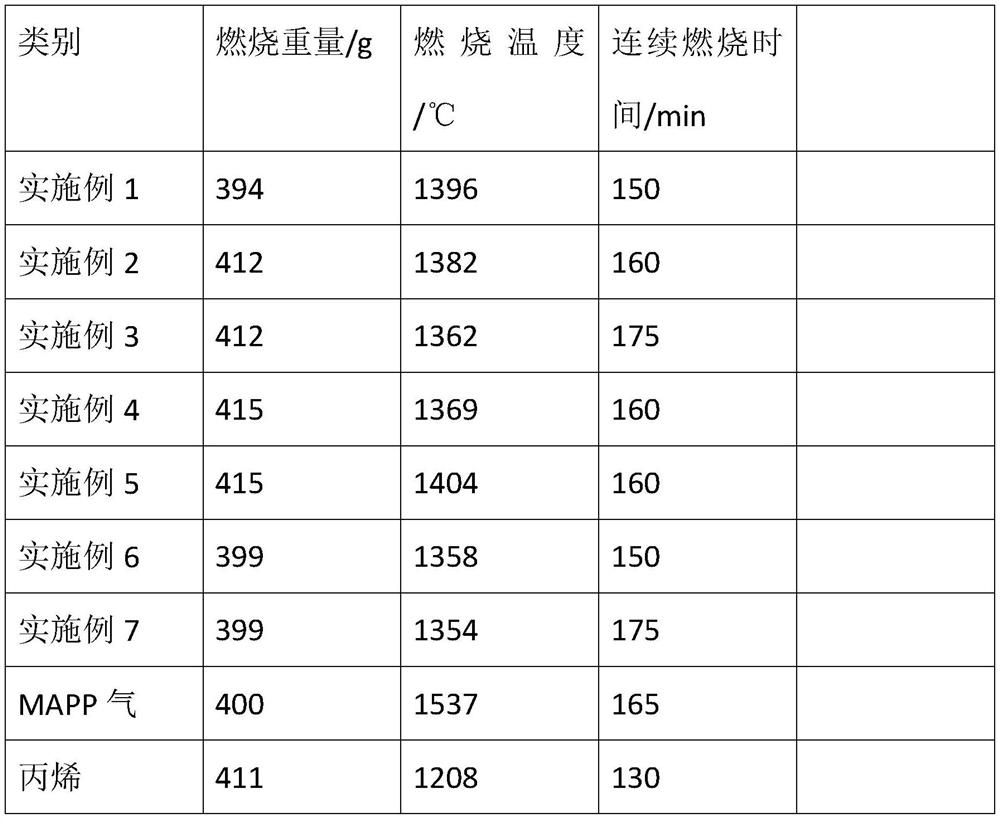

Embodiment 1

[0026] The liquefied gas that replaces MAPP is obtained by mixing and preparing two liquefied gases of propylene and dimethyl ether at a mass ratio of 9:1. In the case of no need for pure oxygen combustion, its actual combustion temperature can reach 1396°C, and the continuous combustion time is 150 minutes. Using it for 1 hour will not cause the barrel of the welding torch to heat up, and the welding effect is good.

[0027] Combustion performance test and tools:

[0028] 1) Thermometer accuracy: ±1°C.

[0029] 2) High-precision thermometer: 0.1°C (below 1000°C). 1°C (above 1000°C). Conditions of use: 0~50℃

[0030] Cold junction temperature: automatic compensation.

[0031] 3) Pressure gauge: accuracy 5psi, measuring range: (0~500psi)

[0032] 4) Electronic balance precision: 0.1g.

[0033] 5) Stopwatch, welding torch, ignition equipment.

[0034] 6) Weigh the empty bottle, take its weight after filling it with liquefied gas that replaces MAPP, and record relevant dat...

Embodiment 2

[0036] It is prepared by mixing two liquefied gases of propylene and dimethyl ether at a mass ratio of 8:2 to obtain a liquefied gas that can replace MAPP. In the case of no need for pure oxygen combustion, its actual combustion temperature can reach 1382°C, and the continuous combustion time is 160 minutes. Using it for 1 hour will not cause the gun barrel of the welding torch to heat up, and the welding effect is good.

Embodiment 3

[0038] It is prepared by mixing two liquefied gases of propylene and dimethyl ether at a mass ratio of 7:3 to obtain a liquefied gas that can replace MAPP. Without pure oxygen for combustion, its actual combustion temperature can reach 1362°C, and the continuous combustion time is 175 minutes. Using it for 1 hour will not cause the barrel of the welding torch to heat up, and the welding effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com