Method for producing glycolate

A glycolic acid ester and oxalic acid ester technology, which is applied in the preparation of carboxylate esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low yield of glycolic acid esters and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

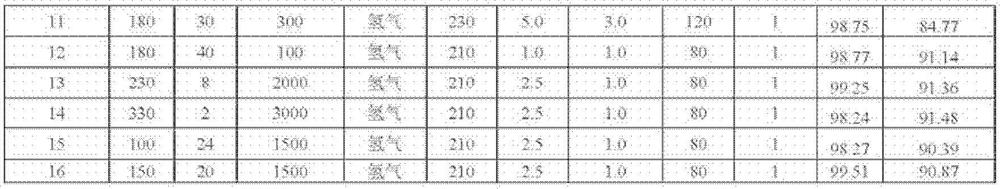

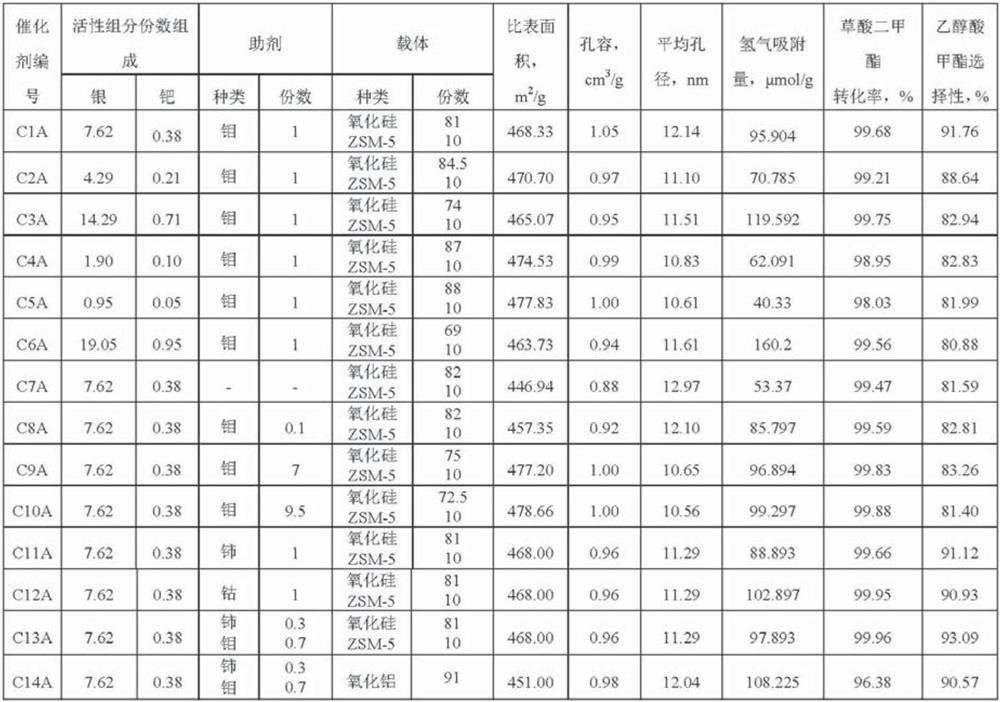

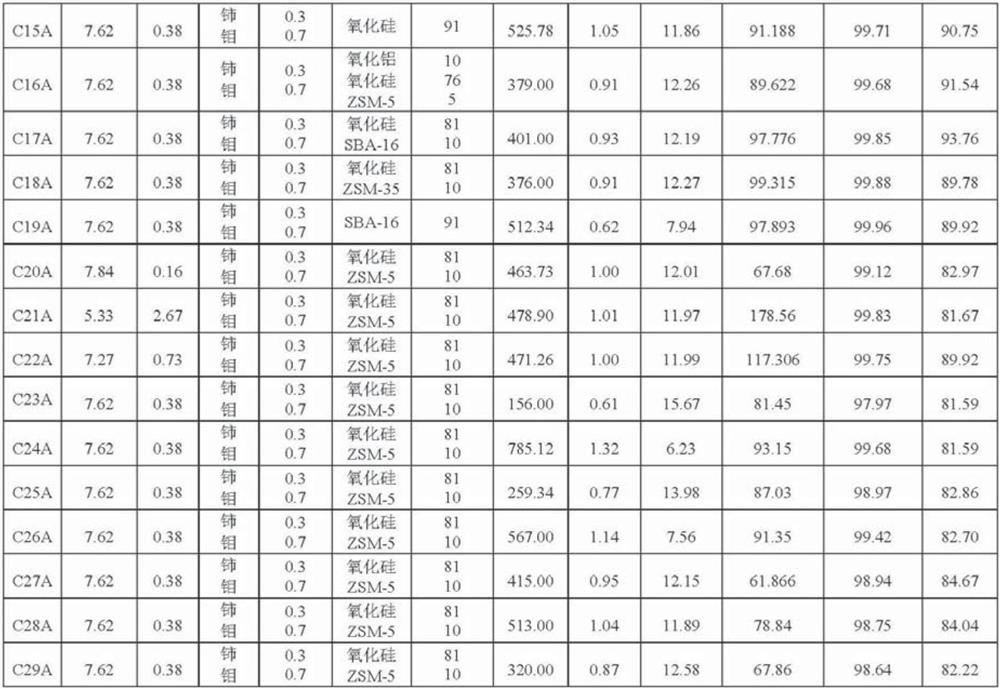

Examples

Embodiment 1

[0037] A certain amount of silver nitrate, palladium nitrate and ammonium molybdate is added to 1 liter of deionized water, and it is mixed with solution I containing 0.07mol / L silver nitrate, 0.0036mol / L palladium nitrate and 0.01mol / L ammonium molybdate, under stirring The specific surface area of 81g is 448.33m 2 / g, average pore diameter 12.51nm, pore volume 1.09cm 3 The ratio of silicon dioxide per gram to 10g silicon aluminum is 316, and the specific surface area is 220.4m 2 / g, average pore diameter 3.44nm, pore volume 0.45cm 3 / g of ZSM-5 was added to solution I to obtain slurry II, and then 3mol / L ammonium bicarbonate water was added to slurry II as a precipitant, and the pH at the end point was controlled to be 6.5, aged at 100°C for 6 hours, and then After filtering and washing the slurry, the obtained filter cake was dried at 120°C for 10 hours, calcined at 400°C for 5 hours, and pressed into tablets after calcined to obtain the catalyst CA1 for oxalate ester s...

Embodiment 2

[0039] A certain amount of silver nitrate, palladium nitrate and ammonium molybdate is added to 1 liter of deionized water, and it is mixed with solution I containing 0.04mol / L silver nitrate, 0.002mol / L palladium nitrate and 0.01mol / L ammonium molybdate, under stirring The specific surface area of 84.5g is 448.33m 2 / g, average pore diameter 12.51nm, pore volume 1.09cm 3 The ratio of silicon dioxide per gram to 10g silicon aluminum is 316, and the specific surface area is 220.4m 2 / g, average pore diameter 3.44nm, pore volume 0.45cm 3 / g of ZSM-5 was added to solution I to obtain slurry II, and then 3mol / L ammonium bicarbonate water was added to slurry II as a precipitant, and the pH at the end point was controlled to be 6.5, aged at 100°C for 6 hours, and then After filtering and washing the slurry, the obtained filter cake was dried at 120°C for 10 hours, calcined at 400°C for 5 hours, and pressed into tablets after calcined to obtain the catalyst CA2 for synthesizing g...

Embodiment 3

[0041] A certain amount of silver nitrate, palladium nitrate and ammonium molybdate is added to 1 liter of deionized water, and it is mixed with solution I containing 0.14mol / L silver nitrate, 0.0068mol / L palladium nitrate and 0.01mol / L ammonium molybdate, under stirring The specific surface area of 74g is 448.33m 2 / g, average pore diameter 12.51nm, pore volume 1.09cm 3 The ratio of silicon dioxide per gram to 10g silicon aluminum is 316, and the specific surface area is 220.4m 2 / g, average pore diameter 3.44nm, pore volume 0.45cm 3 / g of ZSM-5 was added to solution I to obtain slurry II, and then 3mol / L ammonium bicarbonate water was added to slurry II as a precipitant, and the pH at the end point was controlled to be 6.5, aged at 100°C for 6 hours, and then The slurry was filtered and washed, and the obtained filter cake was dried at 120°C for 10 hours, calcined at 400°C for 5 hours, and pressed into tablets after calcined to obtain the catalyst CA3 for synthesizing gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com