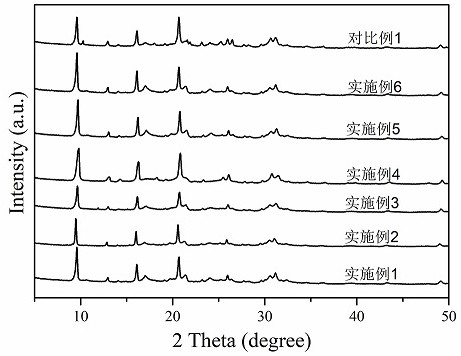

Preparation method of hierarchical pore SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve catalyst, molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of expensive organic templates, inability to realize industrialization, increase synthesis cost and environmental pollution, and achieve Improve selectivity, slow down the formation of carbon deposits, and increase the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

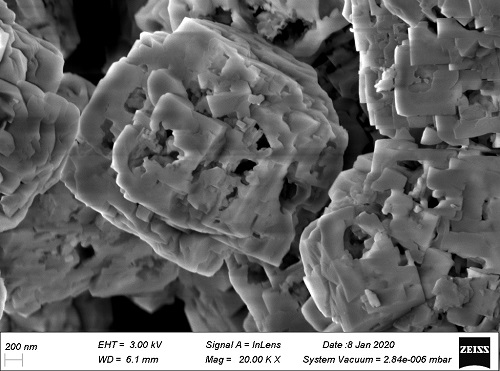

Embodiment 1

[0049] Preparation of aluminum phosphate balls: Add 0.1mol / L newly prepared aluminum phosphate solution and 0.1mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 3 hours of hydrothermal treatment at 90°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product is nearly spherical in shape with an average particle size of 100nm.

[0050] Mix and grind aluminum phosphate balls and white carbon black in a mortar for 20 minutes to obtain a precursor dry powder; place the obtained precursor dry powder in a polytetrafluoro cup on the upper part of the crystallization kettle, and the polytetrafluoro cup is supported by a bracket. Place deionized water and triethylamine at the bottom; the molar ratio of each component in the reactor is 1.5 triethylamine: 17H 2 O: 0.5SiO 2 : 1Al 2 o 3 : 1P 2 o 5 . Seal the crystallization ket...

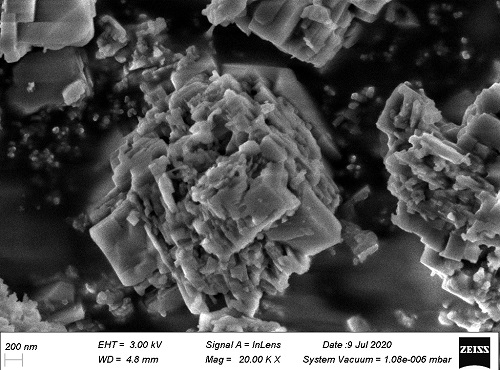

Embodiment 2

[0053] Preparation of aluminum phosphate balls: Add 0.1mol / L newly prepared aluminum phosphate solution and 0.1mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 3 hours of hydrothermal treatment at 90°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product is nearly spherical in shape with an average particle size of 100nm.

[0054] Mix and grind aluminum phosphate balls and silica sol in a mortar for 20 minutes to obtain a precursor, dry it in an oven, and grind it into a powder after the water evaporates completely to obtain a dry powder of a molecular sieve precursor; In the polytetrafluoro cup on the upper part of the crystallization kettle, the polytetrafluoro cup is supported by a bracket, and deionized water and morpholine are placed at the bottom of the kettle; the molar ratio of each component in the reaction k...

Embodiment 3

[0057] Preparation of aluminum phosphate balls: Add 0.2mol / L newly prepared aluminum phosphate solution and 0.2mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 2 hours of hydrothermal treatment at 100°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product has a nearly spherical shape with an average particle size of 200nm.

[0058] Mix and grind aluminum phosphate balls, tetraethyl orthosilicate and triethanolamine in a mortar for 10 minutes to obtain dry precursor powder; place the dry precursor powder in the polytetrafluoro cup on the upper part of the crystallization kettle Supported by a bracket, deionized water is placed at the bottom of the kettle; the molar ratio of each component in the reactor is 3 triethanolamine: 20H 2 O: 0.6SiO 2 : 1Al 2 o 3 : 1P 2 o 5 . Seal the crystallization kettle and place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com