Preparation and application of hollow tubular conductive polymer composite fiber aerogel material

A technology of conductive polymer and composite fiber, which is applied in the field of composite materials, can solve the problems of reducing the heat storage density of composite phase change materials, reducing the heat storage performance of composite phase change materials, and limited improvement of thermal conductivity, so as to achieve good light-thermal Transformation characteristics, ease of large-scale production, effects of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

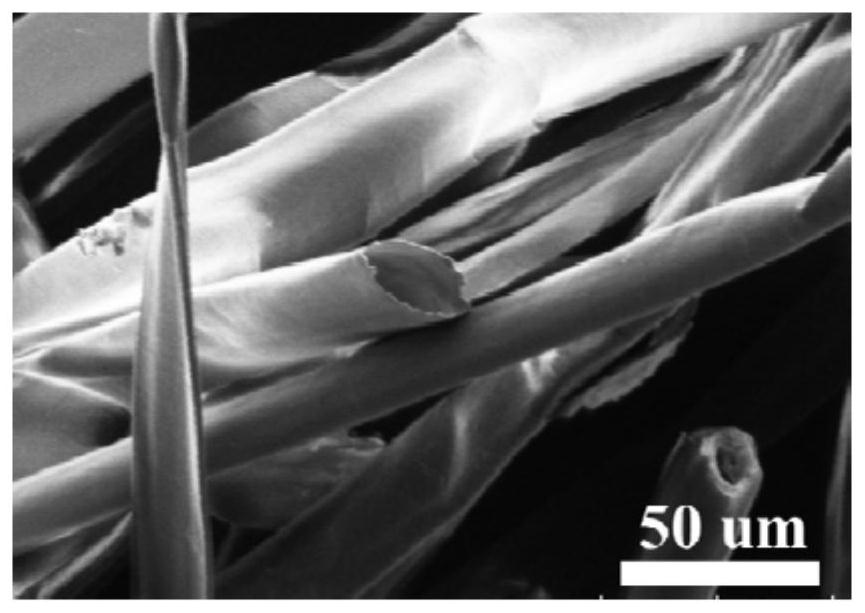

[0027] Step 1: Soak the kapok fiber in a sodium hydroxide solution with a mass concentration of 1 wt%, and treat it at 20°C for 10 minutes to remove the lipid on the fiber surface, then wash it with ethanol and water, and dry it to obtain a hydrophilic kapok fiber.

[0028] Step 2: Take a certain amount of hydrophilic kapok fiber and add it to the water to disperse evenly, then add a certain amount of pyrrole monomer and ferric chloride to the solution, and fully mix and react for 0.5h at -10°C to make the pyrrole monomer in the kapok The fibers are oxidized and polymerized on the inner and outer tube walls, and filtered to obtain polypyrrole-coated modified kapok fibers after the reaction.

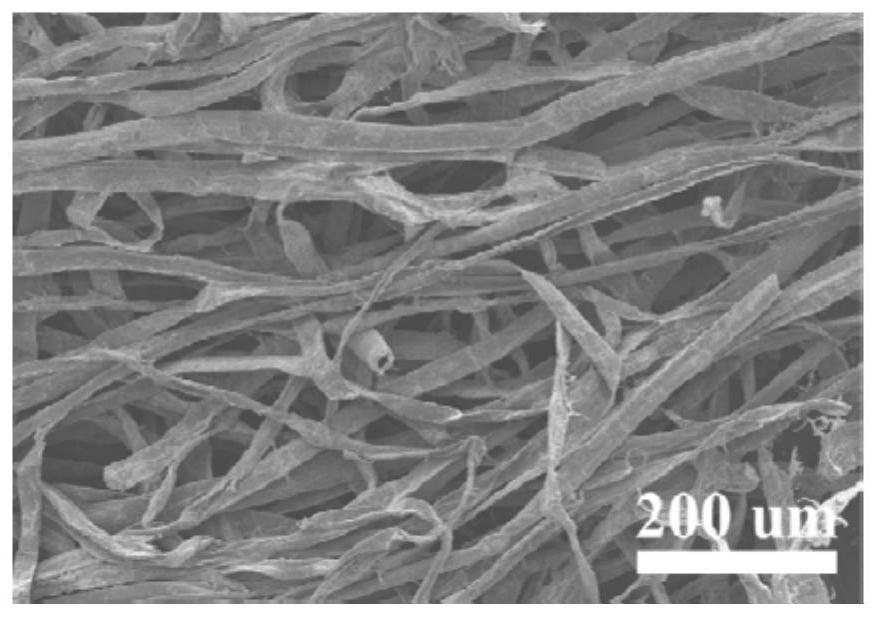

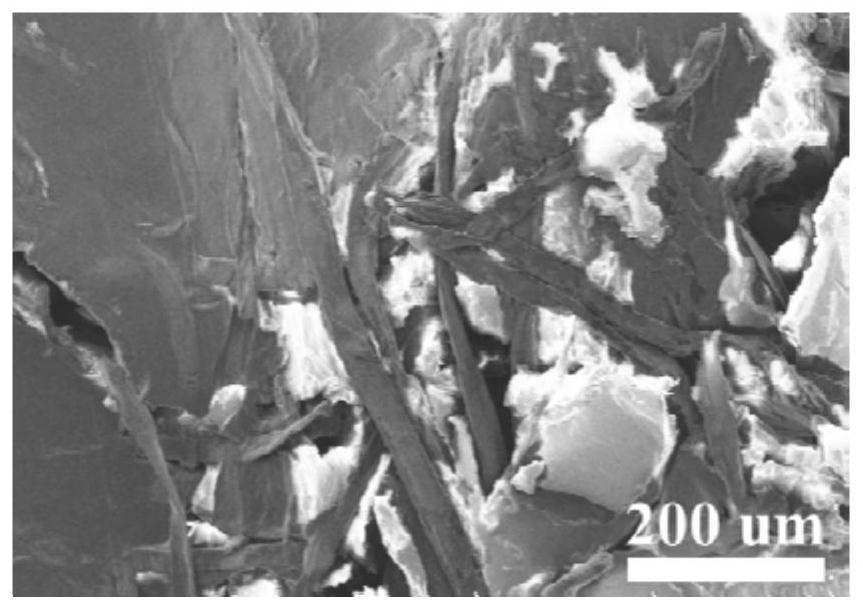

[0029] Step 3: The kapok fiber modified by the polypyrrole coating obtained in the above steps is fully mixed with water according to a mass ratio of 1:5 to form a uniform mixed solution, and liquid nitrogen is used to quickly freeze the mixed solution, and the frozen sample is Freeze-dry...

Embodiment 2

[0033] Step 1: Soak the kapok fibers in a sodium hydroxide solution with a mass concentration of 3wt%, and treat them at 60°C for 30 minutes to remove the lipids on the fiber surface, then wash them with ethanol and water, and dry them to obtain hydrophilic kapok fibers.

[0034] Step 2: Take a certain amount of hydrophilic kapok fiber and add it to the water to disperse evenly, then add a certain amount of pyrrole monomer and ammonium persulfate to the solution, and fully mix and react at 10°C for 2 hours to make the pyrrole monomer inside and outside the kapok fiber Oxidative polymerization on the tube wall, and filtration after the reaction to obtain polypyrrole-coated modified kapok fibers.

[0035] Step 3: The kapok fiber modified by the polypyrrole coating obtained in the above steps is fully mixed with water according to the mass ratio of 1:10 to form a uniform mixed solution, and the mixed solution is quickly frozen with liquid nitrogen, and the frozen sample is Freeze...

Embodiment 3

[0039] Step 1: Soak the kapok fiber in a sodium hydroxide solution with a mass concentration of 5 wt%, and treat it at 80°C for 60 minutes to remove the lipid on the fiber surface, then wash it with ethanol and water, and dry it to obtain a hydrophilic kapok fiber.

[0040]Step 2: Take a certain amount of hydrophilic kapok fiber and add it to the water to disperse evenly, then add a certain amount of aniline monomer and iron sulfate to the solution, and fully mix and react at 60°C for 6 hours so that the aniline monomer is in the inner and outer tubes of the kapok fiber The wall is oxidized and polymerized, and after the reaction is completed, the polyaniline-coated modified kapok fiber is obtained by filtration.

[0041] Step 3: The kapok fiber modified by the polyaniline coating obtained in the above steps is fully mixed with water according to a mass ratio of 1:20 to form a uniform mixed solution, and liquid nitrogen is used to quickly freeze the mixed solution, and the froz...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap