A method for comprehensive recovery of copper-containing sulfur-gold ore charcoal leach barren solution resources

A technology of gold ore and carbon, applied in the direction of metal cyanide, improvement of process efficiency, simple alkali metal cyanide, etc., can solve the problems of thiocyanate recovery or treatment, inability to realize efficient cyanide recovery, chemical consumption, etc. It can shorten the separation and purification process, inhibit the oxidation process of cyanide, and improve the recovery rate of cyanide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

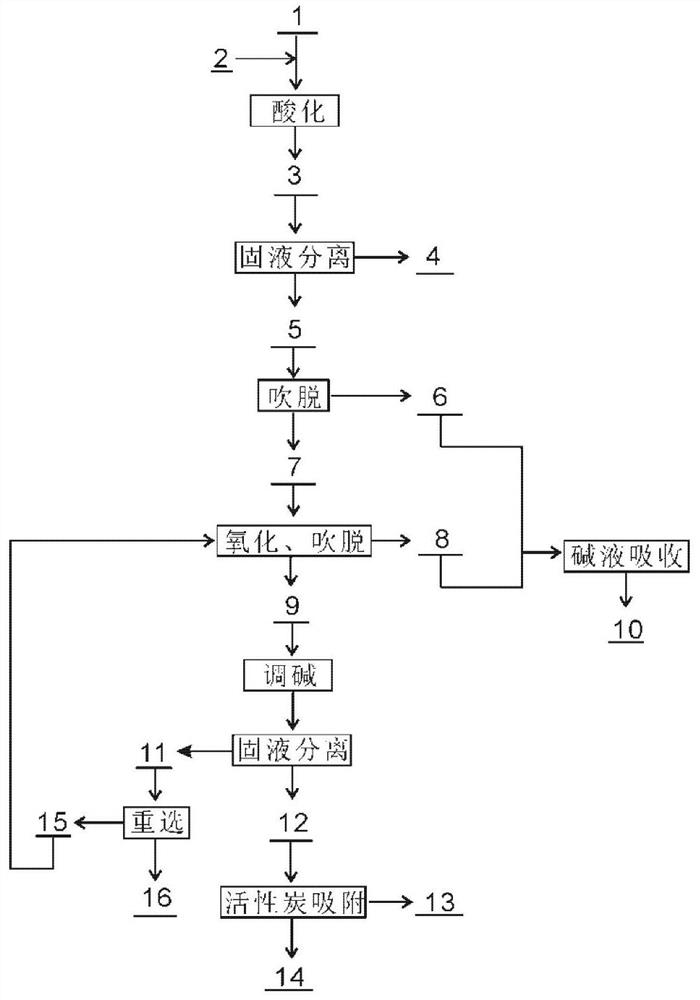

[0028] This embodiment provides a method for comprehensive recovery of copper-containing sulfur-gold ore charcoal leach solution resources, such as figure 1 shown, including the following steps:

[0029] S1. Using acid 2 to adjust the pH value of copper-containing sulfide-gold ore charcoal leach solution 1 to 2.5-3.5, carry out copper precipitation, copper is precipitated in the form of cuprous thiocyanide, and acidified slurry 3 is obtained;

[0030] S2. Separating the acidified slag 3 obtained in step S1 from solid to liquid to obtain a copper concentrate 4 and a copper-removed liquid 5, wherein the copper concentrate 4 can be sold to a smelter for copper smelting;

[0031] S3. Pump the copper-removed liquid 5 obtained in step S2 to the stripping tower, and obtain the HCN gas 6 and the stripped liquid 7 after stripping; the HCN gas 6 is absorbed by the lye;

[0032] S4, the stripped liquid 7 obtained in step S3 is selectively oxidized by an electrocatalytic oxidation method...

Embodiment 2

[0039] This embodiment provides an application example of the method described in Embodiment 1. Including the following steps:

[0040] S1, the copper-containing sulfur-gold ore charcoal leach solution (concentration of Au 0.20mg / L, concentration of Cu 1000mg / L, total cyanide concentration 1000mg / L, concentration of thiocyanate 10g / L) in the reaction tank with concentrated sulfuric acid For acidification, the pH detection device of the reaction tank is interlocked with the sulfuric acid metering peristaltic pump to control the pH of the reaction at 2.5-3.5, and the reaction is stirred in the reaction tank for 30 minutes. Acidified slurry is obtained.

[0041] S2. Pump the acidified slurry to the deep cone thickener with a slurry pump, and at the same time add a polymer flocculant with a mass concentration of 0.1% to the feed barrel of the thickener, and control the amount of the polymer flocculant to 10g / t dry copper Slag; deep cone dense underflow is filtered and washed wit...

Embodiment 3

[0046] This embodiment provides an application example of the method described in Embodiment 1. Including the following steps:

[0047] S1, with copper-containing sulfur-gold ore charcoal leach solution (concentration 0.05mg / L of Au, the concentration 100mg / L of Cu, total cyanogen concentration 100mg / L, about 200mg / L of thiocyanate concentration) in reaction tank with concentrated Sulfuric acid is acidified, and the pH detection device of the reaction tank is interlocked with the sulfuric acid metering peristaltic pump to control the pH of the reaction at 2.5-3.5, and the reaction is stirred in the reaction tank for 30 minutes.

[0048] S2. Pump the acidified slurry to the deep cone thickener with a slurry pump, and at the same time add a polymer flocculant with a mass concentration of 0.1% to the feed barrel of the thickener, and control the amount of the polymer flocculant to 10g / t dry copper Slag; deep cone dense underflow is filtered and washed with a plate and frame filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com