Cutting fluid composition and application thereof

A technology of composition and cutting fluid, which is applied in the direction of lubricating composition, petroleum industry, etc., and can solve problems such as corrosion resistance of aluminum alloys that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

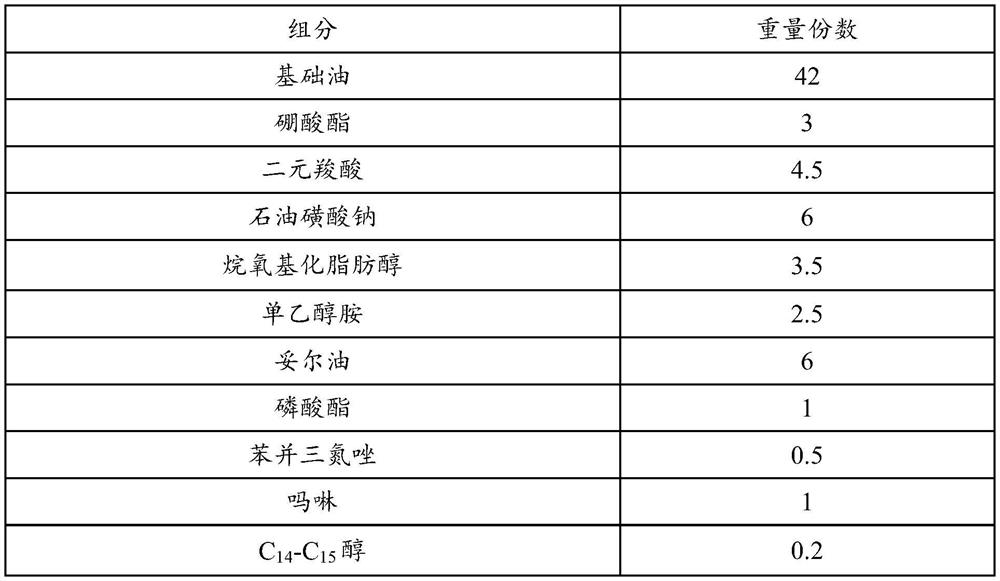

[0021] A cutting fluid composition having excellent aluminum corrosion resistance in a hard water environment comprises the following components, and each component is respectively by weight:

[0022]

[0023]

[0024] The preparation method is as follows:

[0025] (1) First add water and anti-rust agent into the reaction kettle, and fully stir for 1 hour at 40-45°C until the solution is stable and uniform and the whole is transparent;

[0026] (2) Add base oil, oily agent, sulfonate, emulsifier, alcohol amine, defoamer, corrosion inhibitor in sequence, and stir fully at 40-45°C for 1-2 hours;

[0027] (3) After confirming that the temperature is below 40°C, add the fungicide and stir for 30 minutes until it is completely dissolved;

[0028] (4) A stable and uniform liquid can be obtained by adding a couplant at the end, which is the aluminum alloy cutting fluid.

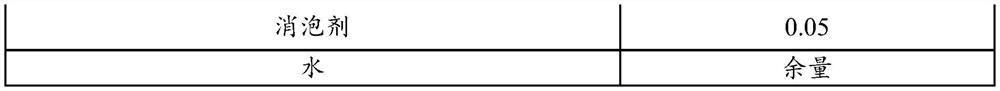

[0029] The aluminum alloy cutting aluminum sheet corrosion test:

[0030] Corrosion test of aluminum she...

Embodiment 2

[0033] A cutting fluid having excellent aluminum corrosion resistance in a hard water environment comprises the following components, and each component is respectively in parts by weight:

[0034] components parts by weight base oil 44 Borate 5 tricarboxylic acid 4 Barium Petroleum Sulfonate 7 C 12 -C 20 Fatty alcohol polyoxyethylene ether

4.2 Triethanolamine 2 Oleic acid 6.5 Phosphonate 1.5 Benzotriazole 0.2 Triazine 2 C 14 -C 15 alcohol

0.3 Defoamer 0.1 water margin

[0035] The preparation method is as follows:

[0036] (1) First add water and anti-rust agent into the reaction kettle, and fully stir for 1 hour at 40-45°C until the solution is stable and uniform and the whole is transparent;

[0037] (2) Add base oil, oily agent, sulfonate, emulsifier, alcohol amine, defoamer, corrosion inhibitor in sequence, and stir fully at 40-45°C for 1-2 hours;

[0038] (3) After ...

Embodiment 3

[0044] A cutting fluid having excellent aluminum corrosion resistance in a hard water environment comprises the following components, and the parts by weight of each component are respectively:

[0045] components parts by weight base oil 46 boric acid 3.5 tricarboxylic acid 5 Sodium petroleum sulfonate 6.5 Alkylphenol polyoxyethylene ether 4 Monoethanolamine 2.2 tall oil 7 Phosphate 1.2 Benzotriazole 0.3 Phenoxyethanol 3 C 14 -C 15 alcohol

0.2 Defoamer 0.12 water margin

[0046] The preparation method is as follows:

[0047] (1) First add water and anti-rust agent into the reaction kettle, and fully stir for 1 hour at 40-45°C until the solution is stable and uniform and the whole is transparent;

[0048] (2) Add base oil, oily agent, sulfonate, emulsifier, alcohol amine, defoamer, corrosion inhibitor in sequence, and stir fully at 40-45°C for 1-2 hours;

[0049] (3) After conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com