A novel dual-mofs electrochemical high-efficiency catalyst composite material and preparation method thereof

An electrocatalytic material and composite material technology, applied in the field of novel dual MOFs electrochemical high-efficiency catalyst composite material and its preparation, can solve the problems of reducing volume capacity and mass capacity, low energy density, etc., to improve performance and increase specific surface area. , the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

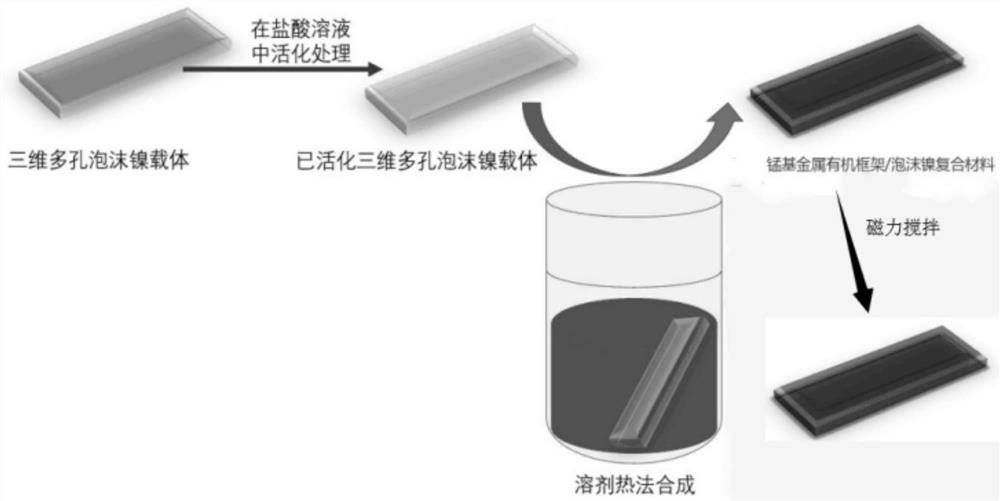

[0058] The invention provides a cobalt-based metal-organic framework / manganese-based metal-organic framework / foamed nickel composite material and a preparation method thereof, including the following procedures and steps:

[0059] Process (1): Take commercially available foam three-dimensional porous nickel foam material, composition: nickel content 99.8%; size: 250mm*200mm*1mm; surface density: 320g / m2±20;

[0060] Process (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0061] Activation solution formula: HCL, concentration 1~10mol / L

[0062] Activation process: temperature 25~60℃, time 1~45min.

[0063] The three-dimensional porous nickel foam material is activated according to the above formula and process to remove the oxide scale on the surface of the three-dimensional porous nickel foam material, and then taken out and dried to obtain an activated three-dimensional porous nickel foam material carrier.

[0064] Process (3): Prepara...

Embodiment 1

[0084] In the above-mentioned specific embodiment,

[0085] Process (1): Prepare foamed three-dimensional porous nickel foam material according to the above "specific implementation method"

[0086] Process (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0087] HCL, concentration 1mol / L, temperature 60℃, time 45min.

[0088] Process (3): Preparation of manganese-based metal organic framework / nickel foam composite material:

[0089] Step 1: Manganese chloride tetrahydrate: 60mg, 2,5-dihydroxyterephthalic acid: 60mg; DMF: 20Ml, deionized water: 1.5ml, absolute ethanol: 1.5ml

[0090] Step 2: Prepare the autoclave according to the above-mentioned "specific implementation method".

[0091] Step 3: Prepare MOF material according to the above "specific implementation method":

[0092] Step (4): prepare MOF material according to the above "specific implementation method";

[0093] Electrochemical test results:

[0094] The MOF material pre...

Embodiment 2

[0097] In the above-mentioned specific embodiment,

[0098] Process (1): Prepare foamed three-dimensional porous nickel foam material according to the above "specific implementation method"

[0099] Process (2): Preparation of activated three-dimensional porous nickel foam material carrier:

[0100] HCL, concentration 3mol / L, temperature 60℃, time 30min.

[0101] Process (3): Preparation of manganese-based metal organic framework / nickel foam composite material:

[0102] Step 1: Manganese chloride tetrahydrate: 120mg, 2,5-dihydroxyterephthalic acid: 60mg; DMF: 20ml, deionized water: 1.5ml, absolute ethanol: 1.5ml

[0103] Step 2: Prepare the autoclave according to the above-mentioned "specific implementation method".

[0104] Step 3: Prepare MOF material according to the above "specific implementation method":

[0105] Step (4): Prepare MOF material according to the above "specific implementation method"

[0106]The MOF prepared above was used as the working electrode of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com