Method for synthesizing CdSe-BiOCl heterojunction

A synthesis method and heterojunction technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve problems such as toxic and harmful chemical reagents, complex synthesis process, etc., and achieve improved photocatalytic The effect of performance, simple preparation process and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

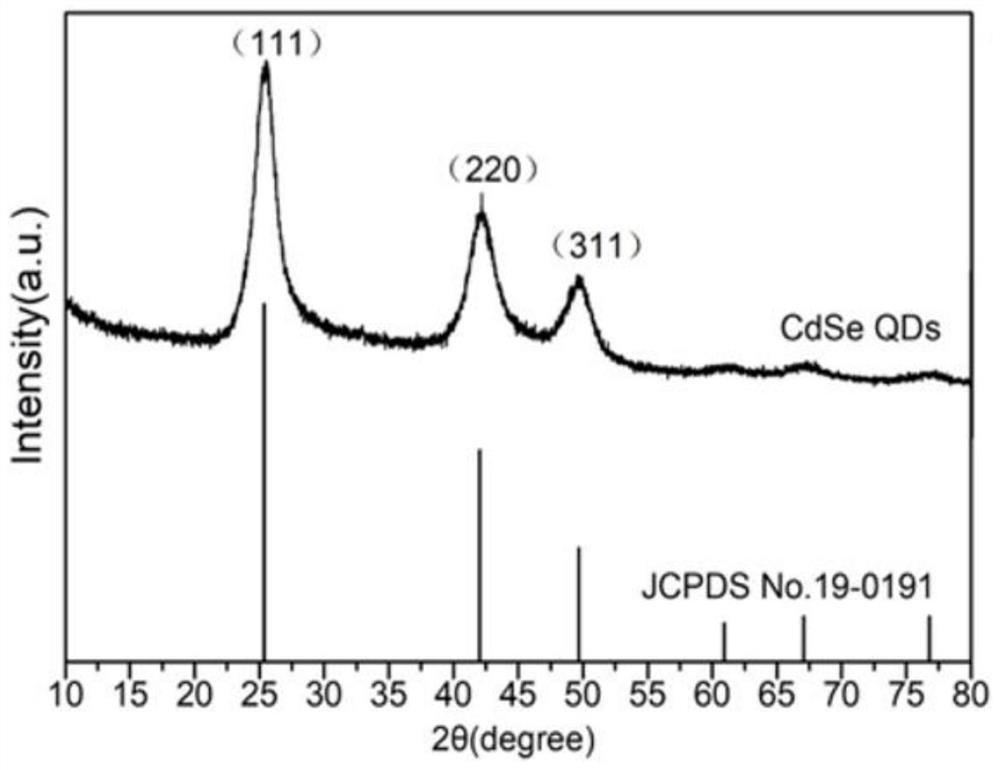

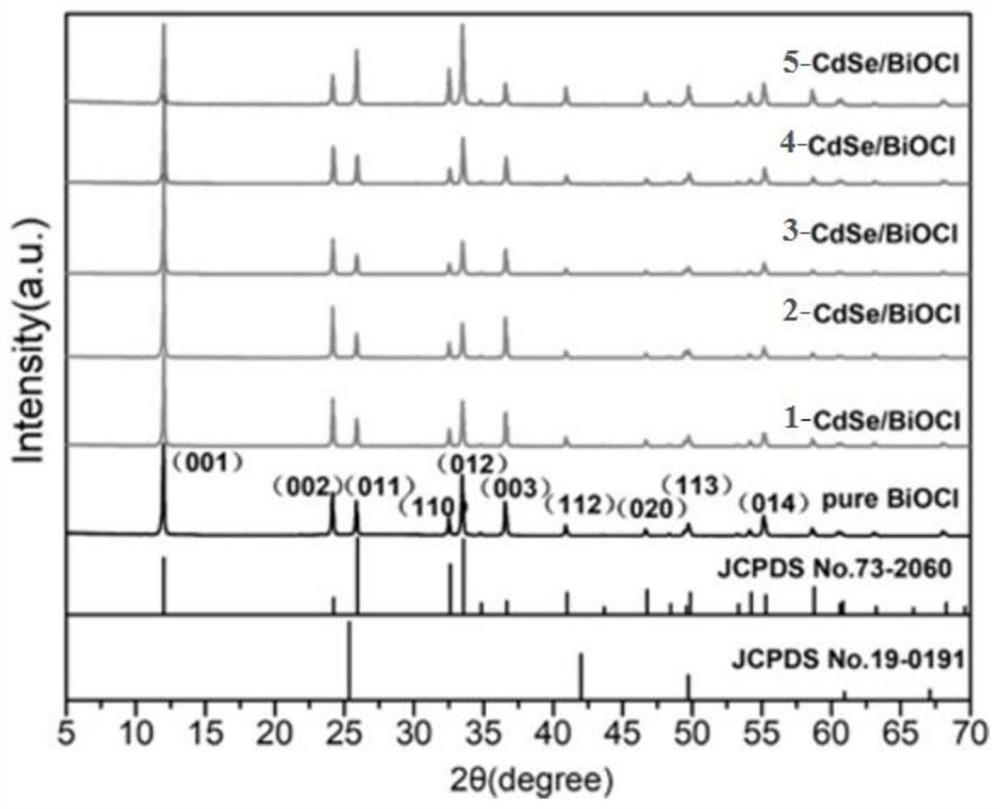

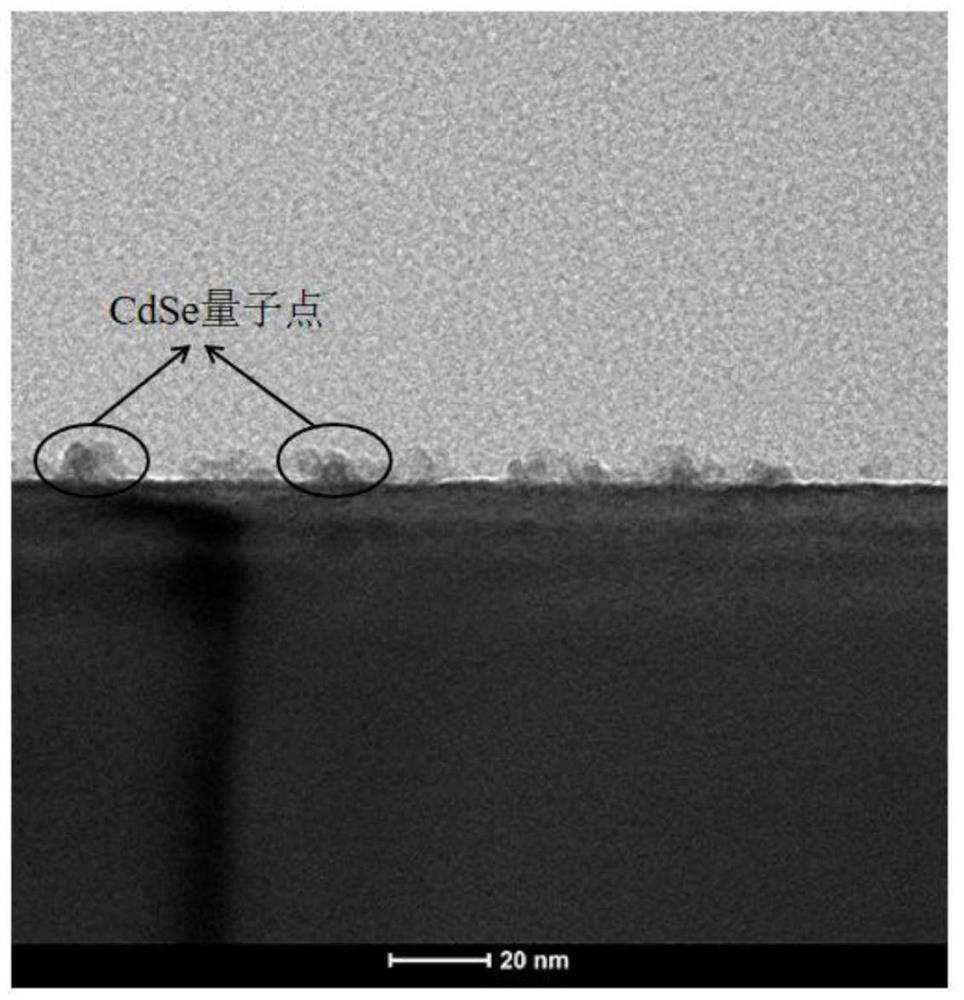

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of BiOCl, weigh 4.850g Bi(NO 3 ) 3 ·5H 2 O and 0.877g NaCl(Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to NaCl was 1:1.5), and 60 mL of deionized water was added, and magnetically stirred until the solid was completely dissolved. The solution was transferred to a polytetrafluoroethylene liner of a 100mL hydrothermal reactor, and reacted at 120°C for 24h. After cooling to room temperature, the product was centrifuged to collect the precipitate, washed three times with deionized water, and dried in an oven at 60°C for 10 h to obtain BiOCl nanosheets.

[0038] 2. Se source precursor preparation, weigh 0.395g selenium powder and 1.975g Na 2 SO 3 (Selenium powder and Na 2 SO 3 The mass ratio of 1:5), and added 30mL deionized water, moved to a 100mL three-necked flask. Under the protection of nitrogen, stir magnetically, and reflux in a constant temperature water bath at 60° C. for 8 hours, and extract the clear liquid by suction filtration to obtain the S...

Embodiment 2

[0042] 1. Preparation of BiOCl, weigh 4.850Bi(NO 3 ) 3 ·5H 2 O and 0.818g NaCl(Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to NaCl is 1:1.4), and magnetically stirred until the solid is completely dissolved. The solution was transferred to the polytetrafluoroethylene lining of a 100mL hydrothermal reactor, and reacted at 135°C for 21h. The product was centrifuged to collect the precipitate, washed three times with deionized water, and dried in an oven at 65 °C for 9 h to prepare BiOCl nanosheets.

[0043] 2. Se source precursor preparation, weigh 0.395g selenium powder and 1.876g Na 2 SO 3 (Selenium powder and Na 2 SO 3 The mass ratio of 1:4.75), and added 30mL deionized water, moved to a 100mL three-necked flask. Under the protection of nitrogen, stir magnetically, and reflux in a constant temperature water bath at 68° C. for 7 hours, and extract the clear liquid by suction filtration to obtain the Se source precursor.

[0044] 3. Dissolve 1.066g of cadmium acetate dihy...

Embodiment 3

[0047] 1. Preparation of BiOCl, weigh 4.850g Bi(NO 3 ) 3 ·5H 2 O and 0.760g NaCl(Bi(NO 3 ) 3 ·5H 2 The molar ratio of O to NaCl is 1:1.3), add 60 mL of deionized water, and stir magnetically until the solid is completely dissolved. The solution was transferred to the polytetrafluoroethylene lining of a 100mL hydrothermal reactor, and reacted at 150°C for 18h. The product was centrifuged to collect the precipitate, washed three times with deionized water, and dried in an oven at 70°C for 8 hours to obtain BiOCl nanosheets.

[0048] 2. Se source precursor preparation, weigh 0.395g selenium powder and 1.778g Na 2 SO 3 (Selenium powder and Na 2 SO 3 The mass ratio of 1:4.5), and added 30mL deionized water, moved to a 100mL three-necked flask. Under the protection of nitrogen, stir magnetically, and reflux in a constant temperature water bath at 75° C. for 6 h, and extract the clear liquid by suction filtration to obtain the Se source precursor.

[0049] 3. Dissolve 1.06...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com