Phosphoric acid treated Trogers Base polymer gas separation membrane as well as preparation method and application thereof

A gas separation membrane and gas separation technology, applied in separation methods, gas treatment, semi-permeable membrane separation, etc., can solve the problems of low separation efficiency and low separation selectivity, achieve high selectivity, wide source of raw materials, phosphoric acid treatment The process is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Example 1: D-Preparation of base polymer film:

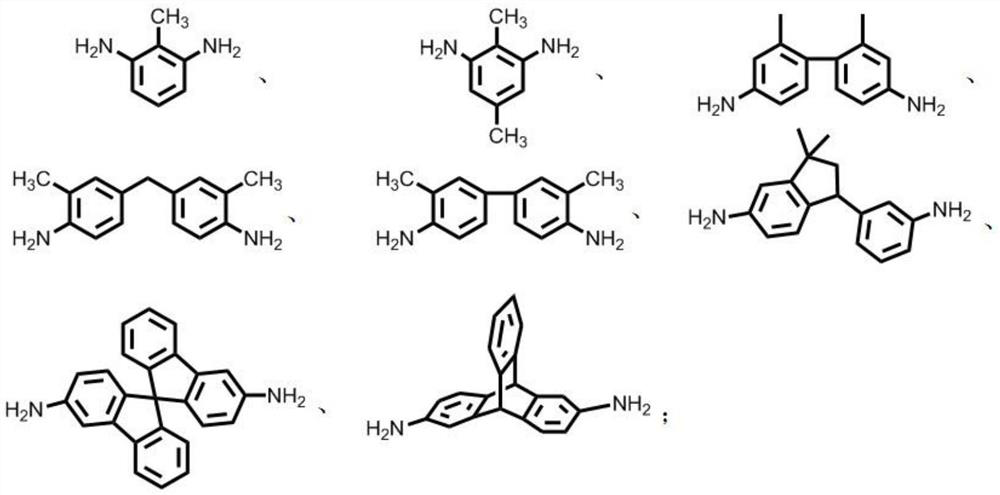

[0038](1) Synthesis of polymer: Under ice bath, add 4,4'-diamino-3,3'-dimethylbiphenyl 10g (47.169mmol) into a three-necked flask with mechanical stirring, and dimethyl biphenyl 21ml (235.8mmol) of formaldehyde was fully dissolved, 80ml of trifluoroacetic acid was slowly added dropwise into it, after stirring at room temperature for 96 hours, the solution was slowly poured into ammonia water, filtered, washed with methanol 3-5 times, and dried.

[0039]

[0040](2)D-Preparation of base polymer film: 0.3g D-The base was dissolved in 3ml of chloroform, filtered, and the obtained polymer solution was slowly poured on a clean glass plate, and allowed to flow naturally, so that the solvent was slowly evaporated at room temperature to form a film, and the obtained film was Soak in methanol for 12 hours, and then dry in a vacuum oven at 120°C for 12 hours. The resulting polymer film has a thickness of approximately 50 μm.

Embodiment 2

[0041]Example 2: M-Preparation of base polymer film:

[0042](1) Synthesis of polymer: Under ice bath, add 4,4'-diamino-3,3'-dimethyldiphenylmethane 10.65g (47.169mmol), and two into a three-necked flask with mechanical stirring. Methanol formal 21ml (235.8mmol), fully dissolved, slowly drip 80ml trifluoroacetic acid into it, after stirring at room temperature for 96 hours, slowly pour the solution into ammonia water, filter, wash with methanol 3-5 times, dry,

[0043]

[0044](2)M-Preparation of base polymer film: 0.3gM-The base was dissolved in 3ml of chloroform, filtered, and the obtained polymer solution was slowly poured on a clean glass plate, and allowed to flow naturally, so that the solvent was slowly evaporated at room temperature to form a film, and the obtained film was Soak in methanol for 12 hours, and then dry in a vacuum oven at 120°C for 12 hours. The resulting polymer film has a thickness of approximately 50 μm.

Embodiment 3

[0045]Example 3: Trip-Preparation of base polymer film:

[0046](1) Synthesis of polymer: Under ice bath, add 13.4g (47.169mmol) of 2,6-triptycene diamine and 21ml (235.8mmol) of dimethanol formal into a three-necked flask with mechanical stirring. Dissolve, slowly add 80ml of trifluoroacetic acid dropwise to it, after stirring at room temperature for 96 hours, slowly pour the solution into ammonia water, filter, wash with methanol 3-5 times, and dry.

[0047]

[0048](2)Trip-Preparation of base polymer film: 0.3gTrip-The base was dissolved in 3ml of chloroform, filtered, and the obtained polymer solution was slowly poured on a clean glass plate, and allowed to flow naturally, so that the solvent was slowly evaporated at room temperature to form a film, and the obtained film was Soak in methanol for 12 hours, and then dry in a vacuum oven at 120°C for 12 hours. The resulting polymer film has a thickness of approximately 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com