Low-temperature-resistant and high-temperature-resistant flame-retardant wire cable

A wire and cable, high temperature technology, applied in the field of low temperature and high temperature flame retardant wire and cable and its preparation, can solve the problems of reduced cold resistance, lack of low temperature resistance flame retardant wire and cable preparation method, cable short-circuit failure, etc., and achieves good flame retardant. Insulation performance, adaptability to mass production, low formulation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

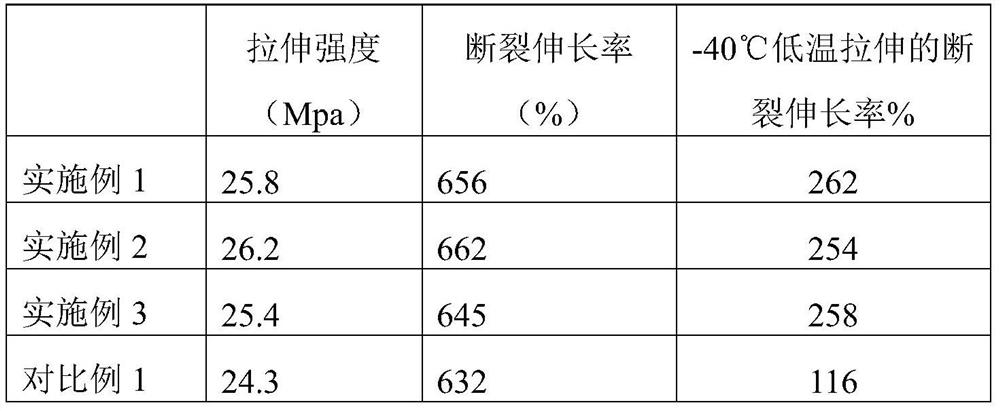

Examples

Embodiment 1

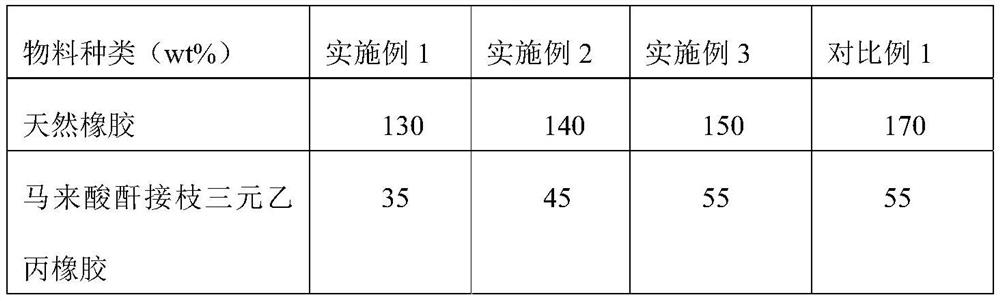

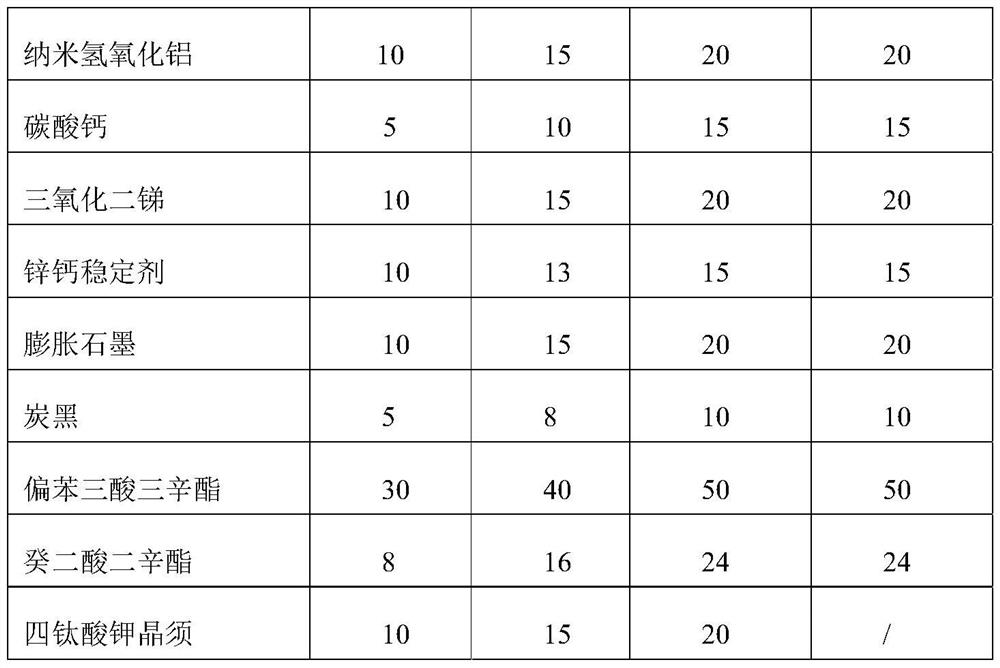

[0033] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0034] (1) Add natural rubber, maleic anhydride grafted EPDM rubber, nano-aluminum hydroxide, calcium carbonate, antimony trioxide, zinc-calcium stabilizer, expanded graphite, and carbon black into a high-speed mixer, and heat to 75 ℃, mix for 20min;

[0035] (2) Add the remaining raw materials to the mixture in step (1), continue mixing for 30 minutes, and leave to age for 5 hours;

[0036] (3) The extrusion temperature of the twin-screw extruder is set to be 175° C., and the screw speed is 125 rpm, and the product obtained in step (2) is added to the twin-screw extruder for extrusion and granulation, and the pellets are cooled to room temperature, screen defective products, and pack to obtain the wire and cable.

Embodiment 2

[0038] (1) Add natural rubber, maleic anhydride grafted EPDM rubber, nano-aluminum hydroxide, calcium carbonate, antimony trioxide, zinc-calcium stabilizer, expanded graphite, and carbon black into a high-speed mixer, and heat to 80 ℃, mix for 15min;

[0039] (2) Add remaining raw materials to the mixture in step (1), continue mixing for 40 minutes, and leave to age for 6 hours;

[0040] (3) The extrusion temperature of the twin-screw extruder is set to be 185°C, and the screw speed is 120 rpm, and the product obtained in step (2) is added to the twin-screw extruder for extrusion and granulation, and the pellets are cooled to room temperature, screen defective products, and pack to obtain the wire and cable.

Embodiment 3

[0042] (1) Add natural rubber, maleic anhydride grafted EPDM rubber, nano-aluminum hydroxide, calcium carbonate, antimony trioxide, zinc-calcium stabilizer, expanded graphite, and carbon black into a high-speed mixer, and heat to 80 ℃, mix for 20min;

[0043] (2) Add remaining raw materials to the mixture in step (1), continue mixing for 40 minutes, and leave to age for 6 hours;

[0044] (3) The extrusion temperature of the twin-screw extruder is set to be 185°C, and the screw speed is 125 rpm, and the product obtained in step (2) is added to the twin-screw extruder for extrusion and granulation, and the pellets are cooled to room temperature, screen defective products, and pack to obtain the wire and cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com