A processing technology of precision seamless steel pipe for gas spring

A seamless steel pipe and processing technology, applied in the direction of metal material coating process, manufacturing tools, furnace types, etc., can solve the problems of reduced function of gas springs and the need for gas springs, etc., to reduce friction, improve sealing, improve The effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

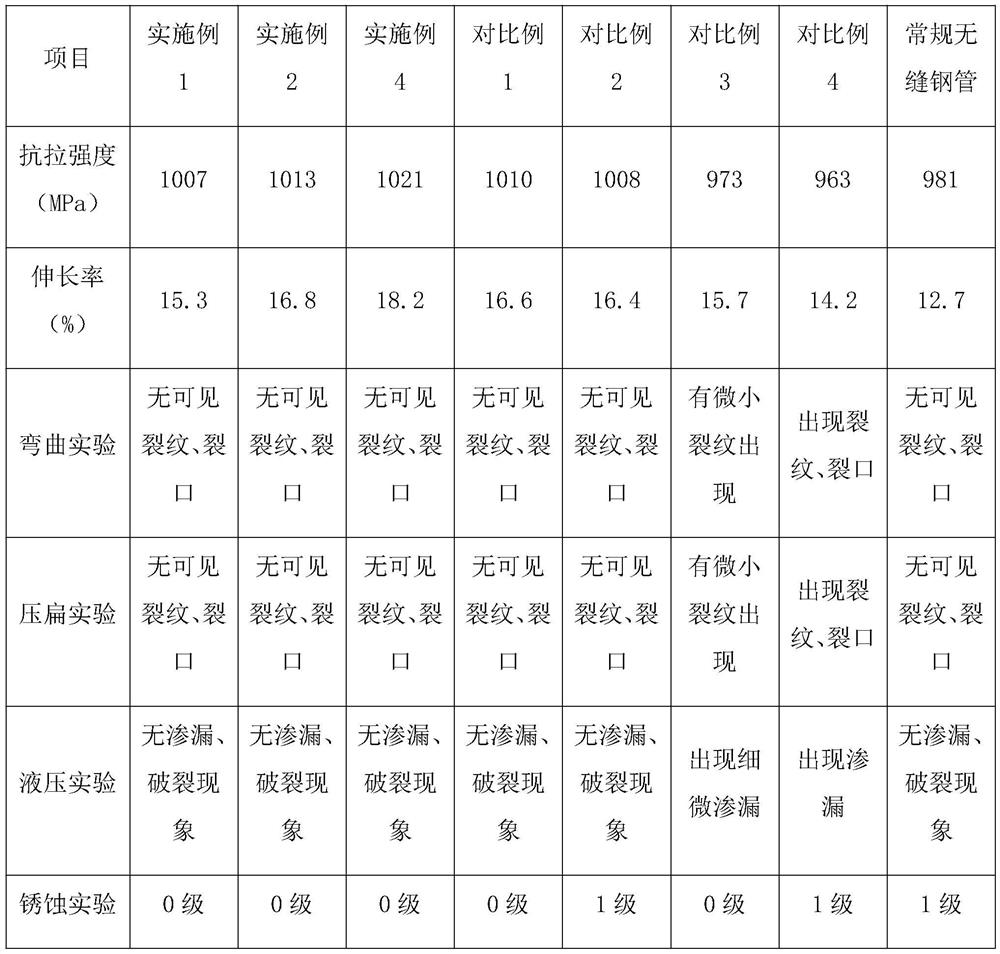

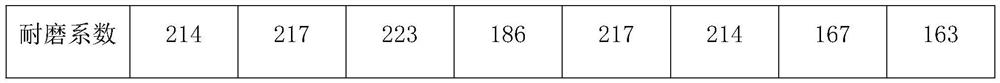

Examples

Embodiment 1

[0038] 1) Preparing steel rods: taking steel billet raw materials into the furnace, adding additives for smelting, then cooling in molds, and preparing steel rods after quenching and tempering treatment;

[0039] 2) Preparing steel pipes: take the steel rods and heat them for piercing and continuous rolling. After removing the pipes and descaling, carry out sizing, cooling and straightening, and cleaning to obtain steel pipes;

[0040] 3) Prepare coating slurry:

[0041] a) Prepare the first slurry:

[0042] Take silicon dioxide and coupling agent and add deionized water to make a dispersion; take aluminum trichloride and add ammonia water to make aluminum hydroxide colloid; take titanium dioxide, chromium carbide, and nickel-chromium alloy particles and add them to the dispersion respectively, and stir After fully mixing, add aluminum hydroxide colloid, stir and mix, dry, and keep at 550°C for 3 hours to prepare ceramic particles. At this time, the ceramic particles contain ...

Embodiment 2

[0053] 1) Preparing steel rods: taking steel billet raw materials into the furnace, adding additives for smelting, then cooling in molds, and preparing steel rods after quenching and tempering treatment;

[0054] 2) Preparing steel pipes: take the steel rods and heat them for piercing and continuous rolling. After removing the pipes and descaling, carry out sizing, cooling and straightening, and cleaning to obtain steel pipes;

[0055] 3) Prepare coating slurry:

[0056] a) Prepare the first slurry:

[0057] Take silicon dioxide and coupling agent and add deionized water to make a dispersion; take aluminum trichloride and add ammonia water to make aluminum hydroxide colloid; take titanium dioxide, chromium carbide, and nickel-chromium alloy particles and add them to the dispersion respectively, and stir After fully mixing, add aluminum hydroxide colloid, stir and mix, dry, and keep at 575°C for 3.5 hours to prepare ceramic particles. At this time, the ceramic particles contai...

Embodiment 3

[0068] 1) Preparing steel rods: taking steel billet raw materials into the furnace, adding additives for smelting, then cooling in molds, and preparing steel rods after quenching and tempering treatment;

[0069] 2) Preparing steel pipes: take the steel rods and heat them for piercing and continuous rolling. After removing the pipes and descaling, carry out sizing, cooling and straightening, and cleaning to obtain steel pipes;

[0070] 3) Prepare coating slurry:

[0071] a) Prepare the first slurry:

[0072] Take silicon dioxide and coupling agent and add deionized water to make a dispersion; take aluminum trichloride and add ammonia water to make aluminum hydroxide colloid; take titanium dioxide, chromium carbide, and nickel-chromium alloy particles and add them to the dispersion respectively, and stir After fully mixing, add aluminum hydroxide colloid, stir and mix, dry, and keep at 600°C for 4 hours to prepare ceramic particles. At this time, the ceramic particles contain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com