Device and process for removing oxalate in sodium aluminate solution

A technology of medium oxalate and removal device, which is applied in the purification of aluminate/alumina/aluminum hydroxide, the preparation of alkali metal aluminate/alumina/aluminum hydroxide, and the aluminum compound, etc., can solve the problem of decomposing foam. , the problem of high alkali consumption and loss of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

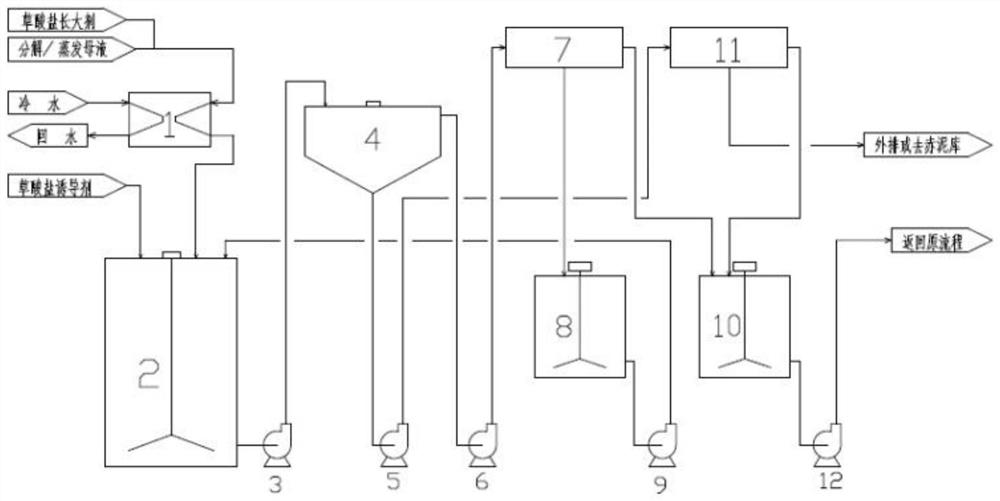

Method used

Image

Examples

Embodiment 1

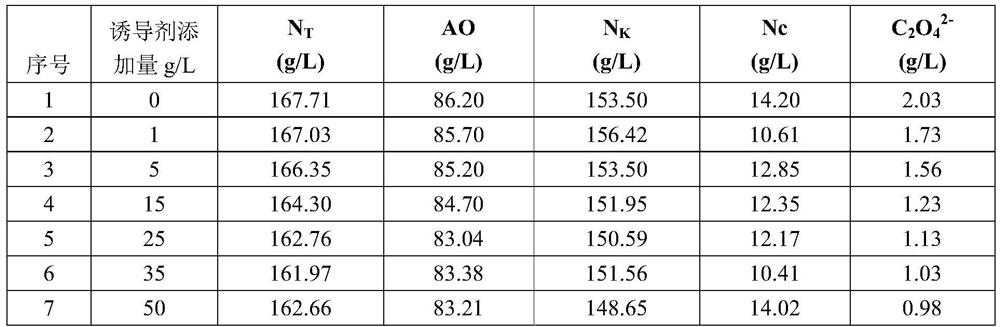

[0058] In a constant temperature water bath shaking device, place 6 groups of 500mL conical beakers, put 250mL decomposition mother liquor in each beaker, add 1, 5, 15, 25, 35, 45g / L yttrium oxalate and 100ppm crystal growth chitosan, the oscillation frequency is 30 Hz, react at a temperature of 60 °C for 2 hours, use a vacuum filtration device to quickly separate the solid from the liquid, and analyze the Na in the filtrate 2 o T (N T ), Al 2 o 3 (AO), Na 2 o k (N K ), Na 2 o C (N C ), Na 2 C 2 o 4 (C 2 o 4 2- ), the experimental results are shown in Table 1.

[0059] Table 1. Embodiment 1 experimental result

[0060]

[0061] It can be seen from Table 1 that as the addition of yttrium oxalate inducer gradually increased from 1g / L, the concentration of oxalate in the sodium aluminate solution decreased gradually after the reaction, and the concentration of oxalate dropped from 2.03g / L to 0.98g / L; When the addition amount is more than 25g / L, the amount of o...

Embodiment 2

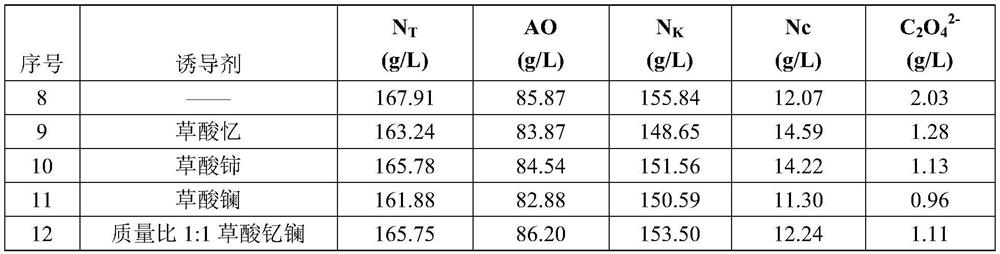

[0063] Place 6 sets of 500mL conical beakers in a constant temperature water bath shaking device, put 250mL decomposition mother liquor in each beaker, add 10g / L yttrium oxalate, cerium oxalate, lanthanum oxalate or their mixture and 100ppm crystal growth agent Chitosan, the oscillation frequency is 30Hz, after reacting at a temperature of 70°C for 6 hours, the solid-liquid separation is carried out quickly with a vacuum filtration device, and the Na in the filtrate is analyzed 2 o T 、Al 2 o 3 、Na 2 o k 、Na 2 o C 、Na 2 C 2 o 4 , the experimental results are shown in Table 2.

[0064] Table 2. Embodiment 2 experimental results

[0065]

[0066]

[0067] It can be seen from Table 2 that adding 10 g / L rare earth oxalate as a crystal inducer in the sodium aluminate solution has a significant effect on inducing the crystallization of sodium oxalate. After the reaction, the concentration of oxalate in the sodium aluminate solution dropped from 2.03 g / L to 0.96 g / L; ...

Embodiment 3

[0069] In a constant temperature water bath oscillation device, place 6 groups of 500mL conical beakers, put 250mL decomposition mother liquor in each beaker, add 10g / L yttrium oxalate, and add 50ppm dextran and chitosan with a molecular weight of about 2 million Sugar, aminopolysaccharide, pullulan, rhamnose, and a mixture of dextran and rhamnose with a mass ratio of 1:1, the oscillation frequency is 30Hz, react at a temperature of 40°C for 1 hour, and then vacuum filter The device quickly performs solid-liquid separation and analyzes Na in the filtrate 2 o T 、Al 2 o 3 、Na 2 o k 、Na 2 o C 、Na 2 C 2 o 4 , the particle size of the filter cake was analyzed with a laser particle size analyzer, and the experimental results are shown in Table 3.

[0070] Table 3. Embodiment 3 experimental results

[0071]

[0072] It can be seen from Table 3 that the addition of 50ppm polysaccharide polymer in the sodium aluminate solution has a significant effect on promoting the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com