Process method for preparing cefradine through microreactor

A technology of microreactor and cephradine, which is applied in the direction of organic chemistry, can solve the problems of large amount of liquid nitrogen, environmental pollution, safety hazards, etc., and achieve the effects of reducing emissions, reducing production costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

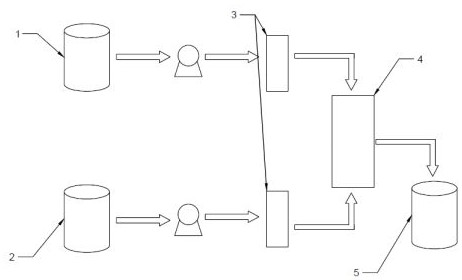

[0024] A kind of processing method preparing cephradine by microreactor, comprises the following steps:

[0025] S1: Preparation of mixed acid anhydride: Dissolve 55g of dihydrodecane salt, 0.3ml of pyridine, and 3.0ml of NMA in 140ml of dichloromethane, add 20ml of pivaloyl chloride after cooling down to generate mixed anhydride in mixed anhydride tank 1.

[0026] S2: Dissolution of 7-ADCA: Dissolve 40 g of 7-ADCA in 7-ADCA tank 2 in 100 ml of dichloromethane, add 30 ml of tetramethylguanidine after cooling down.

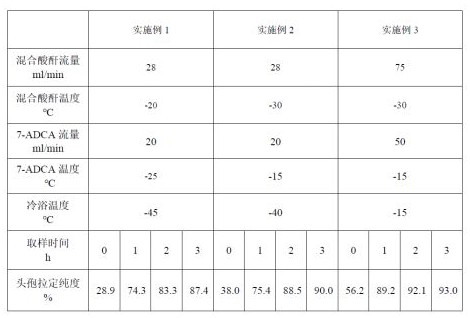

[0027] S3: The mobile phase is mixed acid anhydride with a temperature of -20°C and a flow rate of 28ml / min, and 7-ADCA with a temperature of -25°C and a flow rate of 20ml / min is used as a dispersed phase. 7-ADCA is dispersed through the membrane and microchannel The mixed acid anhydride in the mixture is mixed and reacted in the microreactor 4, and the reaction temperature is -45°C. After the reaction is completed, samples are taken from the storage tank 5 for det...

Embodiment 2

[0030] A kind of processing method preparing cephradine by microreactor, comprises the following steps:

[0031] S1: Preparation of mixed acid anhydride: Dissolve 55g of dihydrodecane salt, 0.3ml of pyridine, and 3.0ml of NMA in 140ml of dichloromethane, add 20ml of pivaloyl chloride after cooling down to generate mixed anhydride in mixed anhydride tank 1.

[0032] S2: Dissolution of 7-ADCA: Dissolve 40g of 7-ADCA in 7-ADCA tank 2 in 100ml of dichloromethane, add 30ml of tetramethylguanidine after cooling down;

[0033] S3: The mobile phase is mixed acid anhydride at a temperature of -30°C and a flow rate of 28ml / min, and the dispersed phase is 7-ADCA at a temperature of -15°C and a flow rate of 20ml / min. 7-ADCA is dispersed through the membrane and microchannel The mixed acid anhydride in the mixture is mixed and reacted in the microreactor 4, and the reaction temperature is -40°C. After the reaction, samples are taken every 1 hour for detection.

[0034] According to the ab...

Embodiment 3

[0036] A kind of processing method preparing cephradine by microreactor, comprises the following steps:

[0037] S1: Preparation of mixed acid anhydride: Dissolve 55g of dihydrodecane salt, 0.3ml of pyridine, and 3.0ml of NMA in 140ml of dichloromethane, add 20ml of pivaloyl chloride after cooling down to generate mixed anhydride in mixed anhydride tank 1.

[0038] S2: Dissolution of 7-ADCA: Dissolve 40g of 7-ADCA in 7-ADCA tank 2 in 100ml of dichloromethane, add 30ml of tetramethylguanidine after cooling down;

[0039] S3: The mobile phase is mixed acid anhydride with a temperature of -30°C and a flow rate of 75ml / min, and the dispersed phase is 7-ADCA with a temperature of -15°C and a flow rate of 50ml / min. 7-ADCA is dispersed through the membrane and microchannel The mixed acid anhydride in the mixture is mixed and reacted in the microreactor 4, and the reaction temperature is -40°C. After the reaction, samples are taken every 1 hour for detection.

[0040] According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com