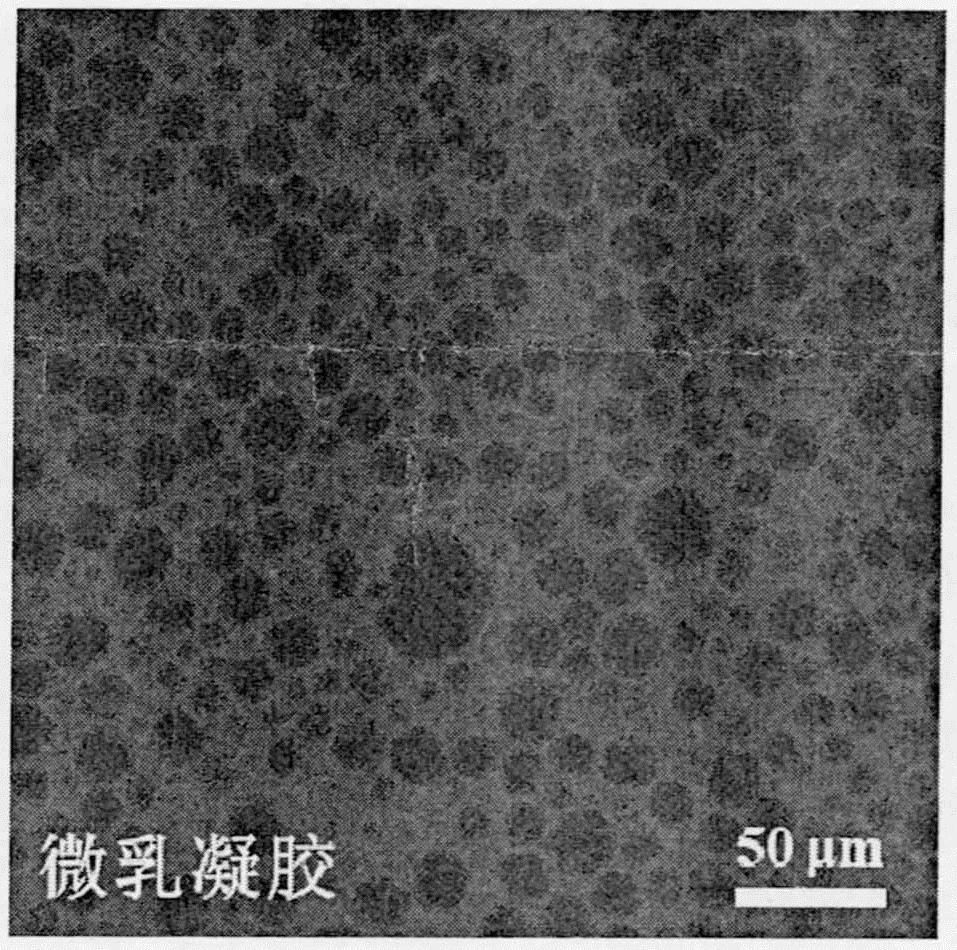

Antibacterial microemulsion gel and preparation method thereof

A technology of microemulsion gel and gelatin, which is applied in the field of biomedical engineering, can solve the problems of inability to achieve therapeutic purposes, lack of fine control of concentration, and low concentration of antibacterial agents, so as to improve resource utilization, reduce resistance to drug-resistant bacterial infections, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 1.25g of B-type gelatin in 25mL of distilled water, stir at 50°C to form a gelatin solution, add 25mL of acetone, remove the supernatant, redissolve the precipitate in 15mL of distilled water and adjust the pH value to 12.0, add dropwise acetone again until A precipitate was generated, and then 250 μL of glutaraldehyde solution (25% aqueous solution) was added to the solution to continue the constant temperature reaction at 50° C. for 3 hours, and the reacted solution was refrigerated and centrifuged at 10,000 g for 30 minutes to obtain gelatin nanoparticles.

[0023] Take 8mL sodium periodate (0.5M) solution and add 10mL dextran aqueous solution (1g, 10%w / v, M w =60000), stirred at room temperature in the dark for 4 hours, and added 10 mL of ethylene glycol solution to terminate the reaction. Afterwards, the solution was fully dialyzed with deionized water and freeze-dried to obtain the oxidized polysaccharide.

[0024] Configure 2mL of continuous phase aqueo...

Embodiment 2

[0026] Dissolve 1.25g of B-type gelatin in 25mL of distilled water, stir at 50°C to form a gelatin solution, add 25mL of acetone, remove the supernatant, redissolve the white precipitate in 15mL of distilled water and adjust the pH value to 12.0, then add acetone dropwise again Until a white precipitate was produced, then 1.25 mL of genipin aqueous solution (10%) was added to the solution to continue the constant temperature reaction at 50° C. for 5 hours, and the reacted solution was refrigerated and centrifuged at 10,000 g for 30 minutes to obtain gelatin nanoparticles.

[0027] Take 8 mL of sodium periodate (0.5M) solution and add 10 mL of sodium hyaluronate aqueous solution (1 g, 10% w / v), stir at room temperature in the dark for 4 hours, and add 10 mL of ethylene glycol solution to terminate the reaction. Afterwards, the solution was fully dialyzed with deionized water and freeze-dried to obtain the oxidized polysaccharide.

[0028] Prepare 1 mL of continuous phase aqueou...

Embodiment 3

[0030]Dissolve 1.25g of B-type gelatin in 25mL of distilled water, stir at 50°C to form a gelatin solution, add 25mL of acetone, remove the supernatant, redissolve the precipitate in 15mL of distilled water and adjust the pH value to 12.0, add dropwise acetone again until A precipitate was generated, and then 625 μL of genipin aqueous solution (5%) was added to the solution to continue the constant temperature reaction at 50° C. for 10 hours, and the reacted solution was refrigerated and centrifuged at 10,000 g for 30 minutes to obtain gelatin nanoparticles.

[0031] Take 8mL sodium periodate (0.5M) solution and add 10mL sodium carboxymethylcellulose aqueous solution (1g, 10%w / v, M w =90000), stirred at room temperature in the dark for 4 hours, and added 10 mL of ethylene glycol solution to terminate the reaction. Afterwards, the solution was fully dialyzed with deionized water and freeze-dried to obtain the oxidized polysaccharide.

[0032] Configure 1.5mL of continuous phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com