Thermal-shock-resistant oxide wave-transparent ceramic material and preparation method thereof

A technology of ceramic materials and thermal shock resistance, which is applied in the field of thermal shock resistant oxide wave-transparent ceramic materials and its preparation, can solve the problems of material damage, limit the application range of materials engineering, poor reliability, etc., reduce the coefficient of thermal expansion and improve mechanical properties Performance and high temperature stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

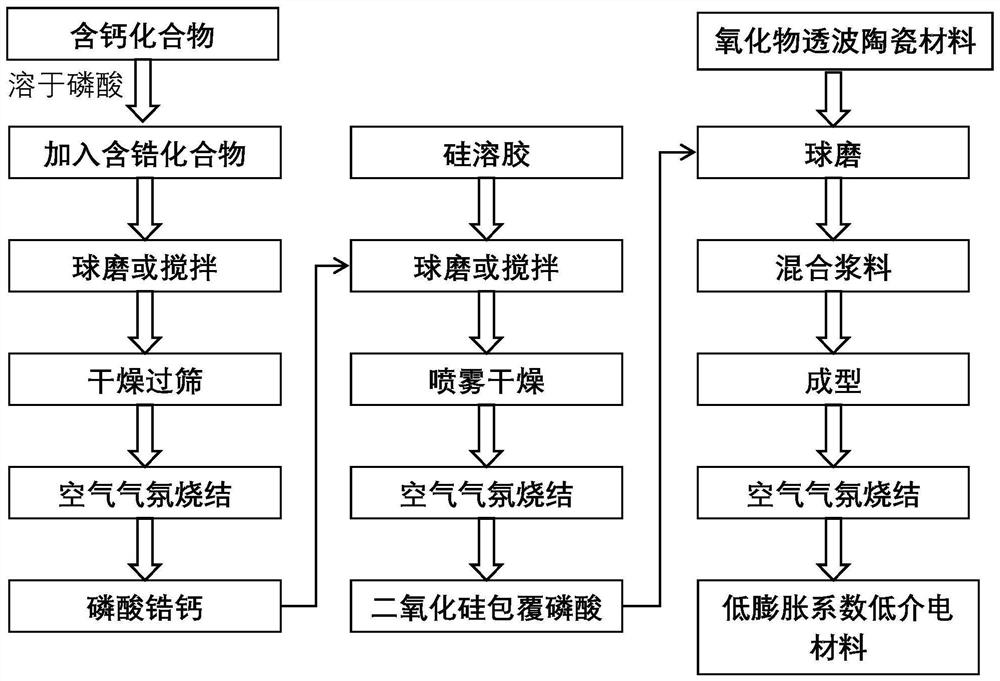

[0039] figure 1 It is a flow chart of the preparation of the thermal shock resistant oxide wave-transparent ceramic material of the present invention. The preparation method of the thermal shock resistant oxide wave-transparent ceramic material comprises the following steps:

[0040] (1) Prepare zirconium calcium phosphate ceramic particles, the specific process is as follows:

[0041] According to CaZr 4 (PO 4 ) 6 According to the corresponding molar ratio, the calcium-containing compound is first dissolved in the phosphoric acid solution, and then the zirconium-containing compound is added, mixed evenly by ball milling or stirring, then dried and sieved, and heat-treated in an air atmosphere to obtain calcium-zirconium phosphate ceramic particles. The calcium-containing compound is one or more of calcium hydroxide, calcium oxide or calcium carbonate, and the zirconium-containing compound is one or more of zirconium oxide, zirconium hydroxide or zirconium carbonate. The ...

Embodiment 1

[0051] According to CaZr 4 (PO 4 ) 6 According to the corresponding molar ratio, calcium hydroxide is firstly dissolved in the phosphoric acid solution, and then zirconium oxide is added, mixed by ball milling, dried and sieved, heat treated at 1400°C for 2 hours, and a well-crystallized calcium zirconium phosphate ceramic powder is obtained.

[0052] Add the calcium zirconium phosphate powder into the silica sol solution and stir evenly. The silica sol accounts for 5% by volume of the coated particles, the average particle diameter of the silica sol is 10nm, and the mass percentage concentration is 4%. It is powdered by spray drying, and then in Heat treatment at 1150°C for 2 hours to obtain calcium zirconium phosphate ceramic particles coated with silica with a particle size of 10 microns.

[0053] In the quartz powder, 18% by volume of silicon dioxide-coated calcium zirconium phosphate ceramic particles is mixed, and the addition ratio of solvent water is 120% of the tota...

Embodiment 2

[0055] According to CaZr 4 (PO 4 ) 6 According to the corresponding molar ratio, firstly dissolve calcium carbonate in the phosphoric acid solution, then add zirconium hydroxide and zirconium carbonate, mix evenly by ball milling, dry and sieve, heat treatment in air atmosphere at 1300°C for 3 hours, and obtain well-crystallized calcium zirconium phosphate ceramic powder .

[0056] Add the calcium zirconium phosphate powder into the silica sol solution and stir evenly. The silica sol accounts for 15% by volume of the coated particles, the average particle diameter of the silica sol is 20nm, and the mass percentage concentration is 10%. Heat treatment at 1250° C. for 1 h in an atmosphere to obtain silicon dioxide-coated zirconium calcium phosphate ceramic particles with a particle size of 25 microns.

[0057] In yttrium silicate (Y 2 o 3 ·SiO2 2 ) The ceramic material powder is mixed with 60% by volume of silica-coated calcium zirconium phosphate ceramic particles, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com