Straw fermenting and curing device based on automatic production and fermenting method thereof

A fermentation device and straw technology, which is applied in the field of straw fermentation and ripening devices, can solve the problems of limiting straw fermentation feed productivity, low degree of automation, and long fermentation time, and achieve the effects of sterilization, high degree of automation, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

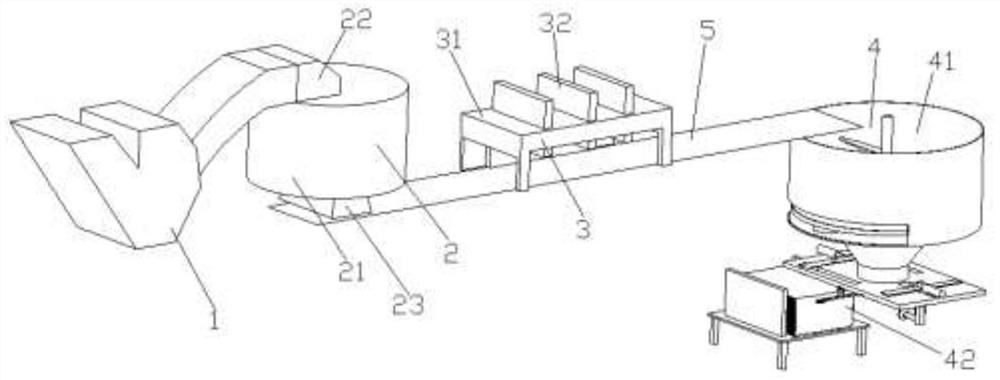

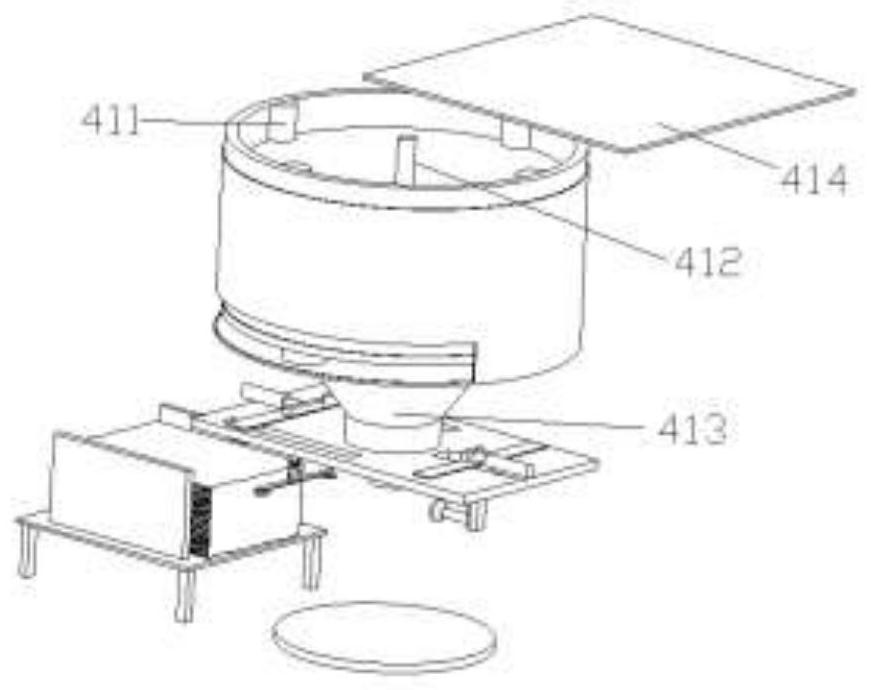

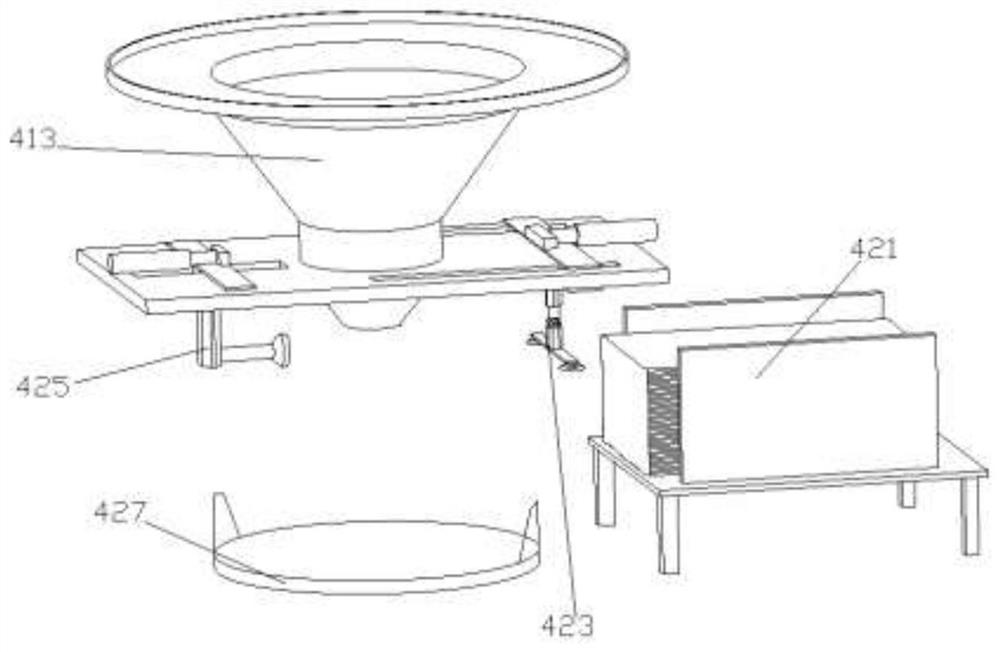

[0033] Embodiment 1: as figure 1 The shown straw fermentation and curing device based on automatic production includes a crusher 1 for crushing straw, a heating unit 2 connected to the discharge port of the crusher 1 for preliminary treatment of the broken straw, and connected to the heating unit 2 for A secondary treatment device 3 for denaturing protein in straw, a bagged fermentation device 4 connected to the secondary treatment device 3, a material conveyor belt 5 for connecting the heating unit 2, the secondary treatment device 3, and the bagged fermentation device 4;

[0034] The heating unit 2 includes a heating tank 21 for steaming the stalks crushed by the crusher 1, a feed box 22 arranged at the upper end of the heating tank 21, a discharge box 23 arranged at the lower end of the heating tank 21, and a heating tank 23 arranged at the lower end of the heating tank. The first agitator inside the body 21; the feed box 22 communicates with the discharge port of the crush...

Embodiment 2

[0055] Embodiment 2: Different from Embodiment 1, a method for fermenting stalks based on an automatic production stalk fermentation and curing device includes the following steps:

[0056] S1: Crushing

[0057] Crushing the corn stalks through the crusher 1;

[0058] S2: thermal stirring denaturation treatment

[0059] Put the crushed corn stalks into the hot tank body 21 through the feed box 22, and then steam treatment for 13 minutes under the condition of 0.8MPa; then discharge the treated corn stalks to the material conveyor belt 5 through the discharge box 23; , the corn stalk on the material conveyor belt 5 is 3kg / m;

[0060] S3: secondary denaturation treatment

[0061] The corn stalks on the material conveyor belt 5 are sprayed with a mass fraction of 1.5% sodium hydroxide solution through the alkalization box 31, and the ultraviolet germicidal lamp tube 32 irradiates the corn stalks; wherein, the material conveyor belt 5 is transported at a speed of 5m / min , the ...

Embodiment 3

[0066] Embodiment 3: Different from Embodiment 1, a method for fermenting stalks based on an automatic production stalk fermentation and curing device includes the following steps:

[0067] S1: Crushing

[0068] Crushing the corn stalks through the crusher 1;

[0069] S2: thermal stirring denaturation treatment

[0070] Put the crushed corn stalks into the hot tank body 21 through the feed box 22, and then steam treatment for 15 minutes under the condition of 1 MPa; then discharge the treated corn stalks to the material conveyor belt 5 through the discharge box 23; wherein, The corn stalk on the material conveyor belt 5 is 3kg / m;

[0071] S3: secondary denaturation treatment

[0072] The corn stalks on the material conveyor belt 5 are sprayed with a mass fraction of 1.5% sodium hydroxide solution through the alkalization box 31, and the ultraviolet germicidal lamp tube 32 irradiates the corn stalks; wherein, the material conveyor belt 5 is transported at a speed of 5m / min ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap